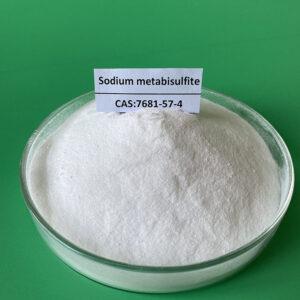

ZINC CHLORIDE

Zinc Chloride (ZnCl₂)

Professional Grade Zinc Chloride 98%+ Purity – Advanced Industrial Chemical

Zinc chloride is a highly versatile inorganic salt widely utilized in galvanizing operations, battery manufacturing, chemical synthesis, wood preservation, and textile processing. Our premium-grade zinc chloride delivers exceptional Lewis acid catalytic properties for organic synthesis, metallurgical fluxing, and specialized industrial applications with consistent performance standards.

✅ 98%+ Industrial & Technical Grade Purity – Superior Quality Control

✅ White Crystalline Granules – High Solubility & Chemical Reactivity

✅ Industrial, Technical & Laboratory Grades Available

✅ CAS 7646-85-7 Certified with Enhanced Storage Stability

✅ Used in Galvanizing, Battery Production, Chemical Synthesis, Wood Treatment, and Textile Processing

Zinc Chloride for Industrial & Chemical Manufacturing Applications

Zinc chloride (ZnCl₂) presents as white, highly hygroscopic granules or crystalline powder with exceptional Lewis acid properties, serving critical functions across galvanizing operations, electrochemical applications, organic synthesis, metallurgical processes, and advanced material manufacturing. This versatile inorganic compound provides unique catalytic and fluxing capabilities essential for metal processing operations, battery technology, and specialized chemical synthesis requiring precise zinc chemistry.

At Chemicals & Process Equipment Limited, we supply technical-grade and industrial-grade Zinc Chloride (98% minimum purity) manufactured under strict quality control protocols and industrial performance specifications. Our product portfolio meets demanding requirements for metallurgical applications, chemical manufacturing, and research applications across diverse industrial sectors.

✅ Technical Grade Standards – CAS 7646-85-7 Specification Compliance

✅ Industrial Quality Control – Metallurgical & Chemical Manufacturing

✅ Laboratory Grade Certification – Research & Development Quality

✅ Multi-Application Platform – Versatile Chemical Performance

✅ Complete Documentation – Comprehensive Quality Assurance Package

Technical Specifications & Chemical Properties

| Property | Specification |

|---|---|

| Chemical Formula | ZnCl₂ |

| CAS Number | 7646-85-7 |

| EC Number | 231-592-0 |

| HS Code | 2827.32.00 |

| Molecular Weight | 136.315 g/mol |

| Appearance | White granules or crystalline powder, hygroscopic |

| Purity | ≥ 98.0% (Technical/Industrial Grade) |

| pH (5% Solution) | 4.0-5.5 |

| Water Solubility | 432 g/100mL at 25°C |

| Density | 2.907 g/cm³ (anhydrous) |

| Melting Point | 290°C |

| Boiling Point | 756°C |

| Heavy Metals | ≤ 50 ppm (as Pb) |

| Packaging Options | 25kg bags, 500kg drums, 1000kg big bags |

Specialized Packaging Solutions:

- 25kg moisture-barrier polyethylene bags with desiccant protection

- 500kg Fiber drums with humidity-controlled interior sealing

- 1000kg Bulk bags for high-volume industrial operations

- Vacuum-sealed packaging for laboratory-grade applications

Metallurgical & Galvanizing Applications

Hot-Dip Galvanizing Operations Zinc chloride finds wide application in metallurgical fluxes, serving as a critical fluxing agent in hot-dip galvanizing processes where it removes oxide films from steel surfaces, ensuring optimal zinc adhesion and coating uniformity. It effectively cleans metal substrates, promotes zinc wetting, and prevents dross formation during galvanizing operations.

Soldering & Metal Processing It is used to clean metal surfaces by dissolving the layer of oxides, ensuring a stronger solder joint. In soldering flux applications, zinc chloride removes oxidation from copper, brass, and other metal surfaces, enabling superior joint formation and enhanced electrical conductivity in electronic assembly operations.

Steel Surface Treatment Zinc chloride functions as an effective pickling agent for steel surface preparation, removing mill scale, rust, and oxide layers prior to galvanizing, painting, or further processing. It provides controlled etching action while maintaining substrate integrity and surface finish quality.

Metallurgical Catalyst Applications In advanced metallurgical processes, zinc chloride serves as a catalyst for metal purification, alloy formation, and specialized heat treatment operations. It facilitates controlled reactions and enables precise metallurgical transformations in high-temperature processing environments.

Chemical Synthesis & Manufacturing Applications

Lewis Acid Catalysis Anhydrous zinc compound is a Lewis acid, readily forming complexes with a variety of Lewis bases, making it invaluable for Friedel-Crafts reactions, aldol condensations, and esterification processes in pharmaceutical and fine chemical manufacturing. A lewis acid used to catalyze the Fischer Indole synthesis an the Friedel-Crafts acylation reactions.

For comprehensive information on zinc chloride applications in Lewis acid catalysis, refer to this detailed catalysis guide by ScienceDirect. Our industrial chemicals expertise provides specialized guidance for optimal catalytic performance.

Organic Compound Production chemical synthesis of organic compounds, such as benzaldehyde, and processes to produce other compounds of zinc. Zinc chloride is used in the manufacture of various dyes, intermediate chemicals and solvents such as ethyl acetate, enabling controlled synthesis of aromatic compounds, pharmaceutical intermediates, and specialty chemicals.

Dehydrating & Condensing Agent Used as dehydrating and condensing agent in organic synthesis industry and catalyst for production of vanillin, Cyclamen aldehyde, anti-inflammatory painkillers and cation exchange resin. Zinc chloride removes water from reaction systems and promotes condensation reactions in pharmaceutical manufacturing and specialty chemical production.

Polymerization Catalyst In polymer chemistry, zinc chloride initiates and controls polymerization reactions, particularly in the production of specialty polymers, resins, and advanced materials. Used as solvent of polyacrylonitrile, it enables controlled molecular weight distribution and polymer property optimization.

Battery & Electrochemical Applications

Primary Battery Electrolyte The electrolyte consists of zinc chloride optionally including small amounts of ammonium chloride in heavy-duty carbon-zinc batteries. The zinc chloride cell of the industrial HD type is applied for low to intermediate continuous and intermittent heavy-rate discharge performance.

Secondary Battery Manufacturing Zinc chloride serves as an electrolyte component in rechargeable zinc-based battery systems, providing enhanced ionic conductivity, improved charge-discharge efficiency, and extended cycle life in advanced energy storage applications.

Electroplating Operations electroplating applications utilize zinc chloride as an electrolyte additive, promoting uniform zinc deposition, improving coating adhesion, and enhancing corrosion resistance in decorative and protective plating processes.

Advanced Electrochemical Systems In fuel cells and specialized electrochemical devices, zinc chloride functions as an ionic conductor, corrosion inhibitor, and performance enhancer for next-generation energy conversion and storage technologies.

Textile & Dyeing Applications

Textile Processing Operations Zinc chloride finds wide application in textile processing, where it serves as a mercerizing agent, sizing compound, and fabric treatment chemical. Used as mordant, Mercerizing agent and sizing agent in Dyeing industry, ensuring optimal dye penetration and color fastness.

Dye Manufacturing & Processing It has a wide range of applications, many of which are used in printing and dyeing plants and in the production of dyes. Zinc chloride functions as a mordant in textile dyeing, fixing dyes permanently to fabric fibers and enhancing color intensity and wash fastness.

Fabric Finishing & Treatment In textile finishing operations, zinc chloride provides flame retardant properties, antimicrobial treatment, and fabric conditioning effects. It improves textile durability, appearance, and functional performance characteristics.

Fiber Processing & Modification Zinc chloride enables controlled fiber modification, including cellulose dissolution, fiber swelling, and surface treatment operations that enhance textile processing efficiency and final product quality.

Wood Preservation & Treatment Applications

Wood Protection Systems It acts as a fungicide, protecting wood from rot and decay. wood preservation applications utilize zinc chloride’s biocidal properties to prevent fungal attack, insect infestation, and moisture-related deterioration in treated lumber and engineered wood products.

Timber Impregnation Processes Zinc chloride penetrates deeply into wood structures, providing long-term protection against biological degradation while maintaining wood strength and dimensional stability. It enables controlled preservation treatment for construction lumber and specialty wood applications.

Fire Retardant Wood Treatment fire retardants incorporate zinc chloride to reduce wood flammability, delay ignition, and minimize flame spread in treated wood products. It provides Class A fire rating compliance for structural and architectural applications.

Advanced Wood Modification In engineered wood manufacturing, zinc chloride facilitates chemical modification of wood polymers, improving dimensional stability, moisture resistance, and mechanical properties of composite wood products.

Industrial & Specialty Applications

Oil & Gas Industry oil and gas drilling operations employ zinc chloride as a drilling fluid additive, completion brine component, and formation damage prevention agent. It provides density control, fluid loss prevention, and clay stabilization in challenging downhole environments.

Pharmaceutical Manufacturing These compounds find applications in pharmaceuticals, where zinc chloride serves as a reagent in active pharmaceutical ingredient (API) synthesis, drug formulation stabilizer, and analytical testing standard for pharmaceutical quality control.

Ceramic & Advanced Materials applications in pharmaceuticals, catalysts, ceramics, and rubber industries. In ceramic manufacturing, zinc chloride functions as a fluxing agent, sintering aid, and ceramic property modifier for specialty ceramic applications requiring precise chemical composition.

Rubber & Polymer Processing rubber industries utilize zinc chloride as a vulcanization accelerator, polymer modifier, and processing aid in specialty rubber formulations requiring enhanced mechanical properties and chemical resistance.

Antimicrobial & Preservation Applications

Antimicrobial Systems Zinc chloride exhibits antimicrobial and tissue-preserving properties, making it effective for disinfection applications, antimicrobial coatings, and preservation systems requiring broad-spectrum biocidal activity.

Deodorant & Personal Care deodorants incorporate zinc chloride for its odor-controlling and antimicrobial properties. It provides long-lasting protection against bacterial growth and maintains product stability in personal care formulations.

Medical & Healthcare Applications In medical device manufacturing and healthcare applications, zinc chloride serves as a sterilization agent, wound care component, and medical equipment treatment chemical with proven antimicrobial efficacy.

Industrial Preservation Systems Zinc chloride functions as a broad-spectrum preservative in industrial fluids, metalworking coolants, and process chemicals, preventing microbial contamination and maintaining system performance.

Quality Control & Analytical Testing

Comprehensive Quality Assurance Every production batch undergoes rigorous testing to ensure compliance with technical-grade, pharmaceutical, and industrial specifications. Our quality control laboratory employs advanced analytical techniques including ICP-OES analysis, potentiometric titration, and gravimetric methods to verify purity and identify trace contaminants.

Quality testing procedures include:

- Zinc content determination via complexometric titration

- Chloride analysis using potentiometric methods

- Heavy metals testing by atomic absorption spectroscopy

- Moisture content analysis through Karl Fischer titration

- pH measurement using calibrated electrode systems

- Particle size distribution via laser diffraction analysis

Storage & Handling Specifications

Optimal Storage Requirements

- Maintain storage temperature between 15-30°C in controlled humidity conditions

- Protect from moisture exposure using sealed container storage

- Store in dry, well-ventilated areas away from incompatible materials

- Separate from alkalis, strong bases, and reactive metals

- Implement desiccant protection for long-term storage stability

Professional Handling Guidelines

- Use appropriate personal protective equipment including chemical-resistant gloves

- Provide adequate ventilation during material handling and processing operations

- Avoid dust generation through controlled transfer and handling procedures

- Maintain emergency eyewash and safety shower facilities in work areas

- Follow industrial hygiene protocols for chemical handling operations

Solubility & Chemical Compatibility

Enhanced Solubility Properties Zinc Chloride Solution is easily soluble in water, soluble in methanol, ethanol, glycerin, ether, acetone, and insoluble in liquid chlorine. This exceptional solubility profile enables diverse application formulations and processing methods across multiple industrial sectors.

Chemical Compatibility Matrix

- Compatible with most organic solvents and polar compounds

- Forms stable complexes with ammonia and organic amines

- Reacts with alkalis to form zinc hydroxide precipitates

- Compatible with acidic solutions and most metal salts

- Incompatible with strong bases and alkali metal hydroxides

Regulatory Compliance & Documentation

Industrial Safety Standards Our zinc chloride meets international quality standards and regulatory requirements for industrial chemical applications. Complete documentation includes Safety Data Sheets with GHS classification, transportation guidelines per UN/DOT regulations, and occupational exposure limits.

Quality Management Compliance

- ISO 9001 quality management system certification

- cGMP manufacturing practices for pharmaceutical applications

- Complete batch documentation with certificate of analysis

- Regulatory compliance statements for industrial applications

- Environmental impact assessment for sustainable operations

Environmental & Safety Considerations

Environmental Impact Management Zinc chloride applications are designed to minimize environmental impact through controlled usage protocols, waste minimization practices, and responsible disposal methods. It biodegrades naturally to zinc ions and chloride, reducing long-term environmental accumulation.

Workplace Safety Protocols Established occupational exposure limits ensure safe workplace handling during zinc chloride processing and application operations. Proper ventilation, personal protective equipment, and emergency response procedures maintain worker safety and health protection.

Why Choose Chemicals & Process Equipment Limited?

✔ Multi-Grade Excellence – Technical, industrial, and laboratory specifications available ✔ Quality Leadership – Advanced testing ensures consistent high-purity standards

✔ Application Expertise – Technical support across diverse industrial applications ✔ Regulatory Assurance – Complete documentation for industrial and research use ✔ Global Distribution – Reliable supply chain supporting international operations

Our zinc chloride products represent the highest standards in inorganic chemistry, specifically formulated for demanding metallurgical, chemical synthesis, and industrial manufacturing applications. We provide comprehensive technical support, regulatory documentation, and quality assurance to ensure optimal performance across your specialized chemical processes.

For detailed specifications, application protocols, or technical documentation, contact our specialized chemical team. We provide comprehensive support including process optimization, method development, and regulatory compliance assistance to maximize effectiveness in your metallurgical, chemical synthesis, or industrial manufacturing applications.

Reviews

There are no reviews yet.