Water Bottle Grade PET Chip (CP-302)

Water Bottle Grade PET Chip (CP-302)

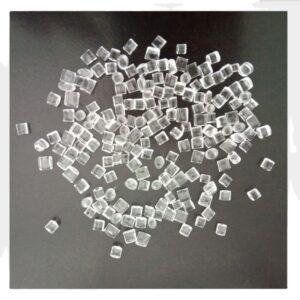

Premium Quality Water Bottle Grade PET Chip (CP-302) – Food-Safe Polyester for Drinking Water Bottles, Beverage Containers, Food Packaging & Consumer Applications

Water Bottle Grade PET Chip (CP-302) are high-performance polyethylene terephthalate resins extensively utilized in drinking water bottle manufacturing, beverage container production, food packaging applications, and consumer products requiring superior clarity, food safety, and exceptional processability.

✅ Ultra-High Performance PET Chip (CP-302) – Superior Clarity & Food-Safe Performance

✅ Water Bottle Specialized Grade – Blow Molding, Injection Stretch, FDA Approved for Beverage Applications

✅ Excellent Barrier Properties – Food Contact Safe, Low Acetaldehyde for Optimal Taste Protection

✅ Multi-Application Compatible – Enhanced Water Bottles, Beverage Containers & Food Packaging Properties

✅ Drinking Water Bottles, CSD Containers, Juice Bottles & Food-Safe Packaging Applications

High-Quality Water Bottle Grade PET Chip (CP-302) for Beverage Manufacturing & Food Packaging

Water Bottle Grade PET Chip (CP-302) represents advanced polyester technology specifically formulated for drinking water bottle manufacturing, beverage container production, food packaging applications, and consumer products requiring exceptional clarity, food safety, and multi-application effectiveness. This essential polyethylene terephthalate serves critical functions across beverage packaging, food containers, water bottle production, and specialized consumer applications requiring controlled transparency, barrier properties, and processing capabilities with exceptional reliability.

At Chemicals & Process Equipment Limited, we supply food-grade Water Bottle Grade PET Chip (CP-302) manufactured under stringent quality control standards and international food safety specifications. Our comprehensive product range includes water bottle grade, CSD bottle grade, hot-fill applications, and custom formulations meeting diverse requirements for beverage manufacturing, food packaging, consumer containers, and specialized applications across global beverage, food packaging, consumer goods, and packaging markets.

✅ Advanced Polyester Technology – Optimized Processing Properties & Multi-Application Performance

✅ Consistent Quality Standards – Multiple Grade Classifications with Comprehensive Food Safety Documentation

✅ Essential Polyethylene Terephthalate – Superior Beverage, Food Packaging & Consumer Container Performance

✅ Multi-Industry Applications – Beverage, Food Packaging, Consumer Containers & Packaging Systems

✅ Technical Support Package – Complete Application Guidance & Performance Optimization

The global bottle grade PET chips market size reached USD 8.5 billion in 2023 and is projected to grow at a robust CAGR of 6.1% from 2024 to 2032, reaching an estimated USD 14.5 billion by the end of the forecast period, while the global PET bottle market reached a value of USD 45.50 Billion in 2024 to reach USD 60.30 Billion by 2033 at a CAGR of 3.2% during 2025-2033. This growth is driven by increasing beverage consumption, expanding bottled water demand, growing food packaging requirements, and rising consumer container applications across global beverage and packaging markets.

Technical Specifications & Water Bottle Grade PET Chip (CP-302) Properties

| Property | CP-302 Water Bottle | Hot-Fill Grade | CSD Bottle Grade | Food Container Grade |

|---|---|---|---|---|

| Intrinsic Viscosity (dL/g) | 0.80-0.84 | 0.82-0.86 | 0.78-0.82 | 0.81-0.85 |

| Density (g/cm³) | 1.33-1.35 | 1.33-1.35 | 1.33-1.35 | 1.33-1.35 |

| Melting Point (°C) | 245-255 | 245-255 | 245-255 | 245-255 |

| Glass Transition Temperature (°C) | 75-85 | 75-85 | 75-85 | 75-85 |

| Crystallization Temperature (°C) | 120-140 | 120-140 | 120-140 | 120-140 |

| Acetaldehyde Content (ppm) | ≤1.0 | ≤1.5 | ≤1.0 | ≤1.0 |

| Diethylene Glycol (%) | ≤1.4 | ≤1.4 | ≤1.4 | ≤1.4 |

| Carboxyl End Groups (meq/kg) | ≤35 | ≤35 | ≤35 | ≤35 |

| Color Value (L*) | ≥80 | ≥80 | ≥80 | ≥80 |

| Color Value (b*) | ≤2.0 | ≤2.0 | ≤2.0 | ≤2.0 |

| Moisture Content (%) | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.2 |

| Haze (%) | ≤1.5 | ≤1.5 | ≤1.5 | ≤1.5 |

| Yellowness Index | ≤4.0 | ≤4.0 | ≤4.0 | ≤4.0 |

| Tensile Strength (MPa) | 55-70 | 55-70 | 55-70 | 55-70 |

| Elongation at Break (%) | 30-150 | 30-150 | 30-150 | 30-150 |

| Flexural Modulus (GPa) | 2.8-3.2 | 2.8-3.2 | 2.8-3.2 | 2.8-3.2 |

| Impact Strength (kJ/m²) | 25-40 | 25-40 | 25-40 | 25-40 |

| Heat Deflection Temperature (°C) | 70-80 | 70-80 | 70-80 | 70-80 |

| Service Temperature (°C) | -40 to +60 | -40 to +85 | -40 to +60 | -40 to +70 |

| Barrier Properties (O₂) | Good | Good | Excellent | Good |

| Barrier Properties (CO₂) | Excellent | Excellent | Excellent | Excellent |

| Processing Temperature (°C) | 270-290 | 270-290 | 270-290 | 270-290 |

| Drying Temperature (°C) | 150-170 | 150-170 | 150-170 | 150-170 |

| Drying Time (hours) | 4-6 | 4-6 | 4-6 | 4-6 |

| Preform Processing | Excellent | Excellent | Excellent | Excellent |

| Blow Molding Performance | Outstanding | Outstanding | Outstanding | Outstanding |

| Injection Molding | Good | Good | Good | Good |

| Stretch Blow Molding | Excellent | Excellent | Excellent | Excellent |

| Food Contact Approval | FDA, EU | FDA, EU | FDA, EU | FDA, EU |

| Storage Conditions | Cool, dry environment | |||

| Shelf Life | 60 months | |||

| Packaging Options | 25kg bags, 1100kg octabins, bulk containers |

Available Grade Types:

- Water Bottle Grade (CP-302) for drinking water applications

- CSD Bottle Grade for carbonated soft drinks

- Hot-Fill Grade for hot-filled beverages and juices

- Food Container Grade for food packaging applications

- Juice Bottle Grade for fruit juice containers

- Sports Bottle Grade for athletic drink containers

- Pharmaceutical Bottle Grade for liquid medicines

- Cosmetic Container Grade for personal care products

- Wide-Mouth Jar Grade for food jars and containers

- Custom Grades for specialized applications

Specialized Processing Solutions:

- Injection stretch blow molding for bottles

- Two-step stretch blow molding for containers

- One-step stretch blow molding for integrated production

- Injection molding for preforms and closures

- Thermoforming for food containers and trays

- Sheet extrusion for packaging applications

- Film extrusion for flexible packaging

- 3D printing for prototyping applications

Water & Beverage Applications

Drinking Water Bottles Beverage manufacturers utilize Water Bottle Grade PET Chip (CP-302) for bottled water containers, purified water bottles, and drinking water packaging requiring water bottle specifications. Water companies employ PET chips for mineral water bottles, spring water containers, and drinking water applications.

Carbonated Soft Drink Bottles CSD manufacturers use Water Bottle Grade PET Chip for cola bottles, soda containers, and carbonated beverage packaging requiring CSD specifications. Beverage companies employ PET chips for soft drink bottles, fizzy drink containers, and carbonated beverage applications.

Juice & Sports Drink Containers Juice manufacturers utilize Water Bottle Grade PET Chip for fruit juice bottles, sports drink containers, and beverage packaging requiring juice specifications. Sports drink companies employ PET chips for energy drink bottles, isotonic containers, and sports beverage applications.

Hot-Fill Beverage Applications Hot-fill manufacturers use Water Bottle Grade PET Chip for tea bottles, coffee containers, and hot-filled beverage packaging requiring hot-fill specifications. Beverage companies employ PET chips for ready-to-drink tea, hot-fill juice, and thermal processing applications.

Food Packaging Applications

Food Container Manufacturing Food packaging manufacturers utilize Water Bottle Grade PET Chip for food jars, sauce containers, and food packaging requiring food container specifications. Food companies employ PET chips for condiment bottles, dressing containers, and food packaging applications.

Dairy & Liquid Food Packaging Dairy manufacturers use Water Bottle Grade PET Chip for milk bottles, yogurt containers, and dairy packaging requiring dairy specifications. Food companies employ PET chips for liquid food containers, dairy bottles, and milk packaging applications.

Edible Oil & Cooking Applications Oil manufacturers utilize Water Bottle Grade PET Chip for cooking oil bottles, edible oil containers, and oil packaging requiring oil packaging specifications. Food companies employ PET chips for vegetable oil bottles, cooking oil containers, and oil packaging applications.

Specialty Food Containers Specialty food manufacturers use Water Bottle Grade PET Chip for honey jars, syrup bottles, and specialty packaging requiring specialty food specifications. Gourmet companies employ PET chips for premium containers, artisan packaging, and specialty food applications.

Consumer & Personal Care Applications

Personal Care Containers Personal care manufacturers utilize Water Bottle Grade PET Chip for shampoo bottles, lotion containers, and personal care packaging requiring cosmetic specifications. Beauty companies employ PET chips for skincare bottles, haircare containers, and personal care applications.

Household Product Containers Household manufacturers use Water Bottle Grade PET Chip for cleaning product bottles, detergent containers, and household packaging requiring household specifications. Consumer companies employ PET chips for home care bottles, cleaning containers, and household applications.

Health & Wellness Products Health manufacturers utilize Water Bottle Grade PET Chip for supplement bottles, vitamin containers, and health product packaging requiring health specifications. Wellness companies employ PET chips for nutraceutical bottles, health drink containers, and wellness applications.

Automotive & Chemical Containers Chemical manufacturers use Water Bottle Grade PET Chip for automotive fluids, chemical containers, and industrial packaging requiring chemical specifications. Industrial companies employ PET chips for lubricant bottles, chemical containers, and automotive applications.

Quality Control & Testing Procedures

Comprehensive Quality Assurance Every production batch undergoes extensive testing to ensure compliance with food contact regulations, beverage packaging standards, and international quality requirements. Our quality control laboratory employs advanced analytical techniques including intrinsic viscosity testing, acetaldehyde analysis, and barrier property evaluation. This brand of product has a favorable processability, low processing temperature and wide processing range. The product has a high transparency and high final product acceptance rate, so the bottle producing process is realized with high production efficiency, low degradation and low aldehydes content.

Quality assurance procedures include:

- Intrinsic viscosity testing using automated viscometer

- Acetaldehyde content analysis using headspace GC-MS

- Color measurement using spectrophotometer

- Thermal analysis using DSC and TGA methods

- Mechanical property testing using universal testing machine

- Barrier property testing using permeation analyzers

- Clarity and haze measurement using nephelometer

- Moisture content testing using Karl Fischer method

- Food contact migration testing using simulants

- Heavy metals analysis using ICP-MS

- Microbial testing for sterility confirmation

- Processing performance evaluation using pilot equipment

- Preform quality testing using blow molding trials

- Bottle performance testing using pressure and drop tests

- Shelf-life stability testing under accelerated conditions

- FDA and EU food contact compliance verification

Application Guidelines & Best Practices

Blow Molding Guidelines Establish proper blow molding procedures for Water Bottle Grade PET Chip (CP-302) including temperature control, preform design, and processing parameters for optimal bottle quality and production efficiency.

Preform Manufacturing Methods Develop appropriate injection molding procedures including temperature profiles, cooling control, and gate design for maximum preform quality and blow molding performance.

Storage & Handling Procedures Implement proper storage conditions including moisture protection, temperature control, and contamination prevention for maintaining PET chip quality and processing performance throughout storage periods.

Market Applications & Industry Trends

Beverage Industry Growth Expanding beverage consumption and growing bottled water markets drive continued growth in water bottle grade PET applications for bottles, containers, and beverage packaging across global beverage operations.

Food Packaging Market Expansion Growing food packaging demand and expanding ready-to-eat markets support increased adoption of food-grade PET for containers, jars, and food packaging applications worldwide.

Sustainability Development Expanding recycling initiatives and growing environmental consciousness drive growth in recyclable PET applications and sustainable packaging solutions.

For comprehensive technical information about PET resin properties, structure, and industrial applications, you can reference this detailed guide on polyethylene terephthalate which provides extensive coverage of PET characteristics, fiber production, blow molding, and bottle manufacturing processes.

Environmental & Regulatory Compliance

Food Contact Standards & Certifications Water Bottle Grade PET Chip (CP-302) complies with FDA food contact regulations, EU plastic regulations, and international food safety guidelines ensuring safe use in beverage and food contact applications.

Beverage Industry Standards & Safety Adherence to beverage industry standards, IBWA guidelines, and international packaging regulations supports responsible use in drinking water and beverage applications.

Environmental Standards & Recycling Compliance with environmental regulations, recycling standards, and sustainability guidelines ensures appropriate use in recyclable packaging and environmental applications.

Performance Advantages & Technical Benefits

✔ Crystal Clear Transparency – Superior optical clarity for premium beverage packaging

✔ Excellent Barrier Properties – Outstanding CO₂ retention and oxygen barrier performance

✔ Low Acetaldehyde Content – Minimal taste transfer for pure beverage flavor

✔ Food Contact Safety – FDA and EU approved for food and beverage applications

✔ Superior Processability – Excellent blow molding and preform manufacturing properties

✔ High Mechanical Strength – Outstanding impact resistance and bottle integrity

✔ Thermal Stability – Good heat resistance for processing and hot-fill applications

✔ Dimensional Stability – Excellent shape retention and manufacturing consistency

✔ Chemical Resistance – Resistance to cleaning chemicals and sterilization processes

✔ Recyclability – 100% recyclable for sustainable packaging solutions

✔ Lightweight Design – Reduced material usage and transportation costs

✔ Cost-Effective Solution – Economical alternative to glass and other materials

Our Water Bottle Grade PET Chip (CP-302) products represent industry-leading standards in polyester technology and beverage packaging solutions, specifically formulated for demanding water bottle operations, beverage applications, food packaging production, and specialized consumer applications. We provide comprehensive technical support, processing guidance, and application consultation to ensure optimal performance across your specialized beverage, food packaging, consumer container, or packaging applications.

For detailed specifications, technical data sheets, or application-specific recommendations, contact our specialized packaging materials division. We offer complete support including processing optimization, equipment recommendations, and technical guidance to maximize effectiveness in your beverage, food packaging, consumer container, or packaging applications.

For more information about our products, feel free to Contact Us today.

Reviews

There are no reviews yet.