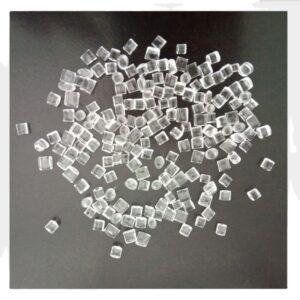

Virgin/ Recycled EVA Resin/ EVA

Virgin/Recycled EVA Resin

Premium Quality Virgin/Recycled EVA Resin – Flexible Copolymer for Footwear Manufacturing, Packaging Applications, Automotive Components & Industrial Uses

Virgin/Recycled EVA Resin are high-performance ethylene vinyl acetate copolymers extensively utilized in footwear manufacturing, flexible packaging applications, automotive components, and industrial products requiring superior flexibility, chemical resistance, and exceptional processability.

✅ Ultra-High Performance EVA Resin – Superior Flexibility & Multi-Industry Performance

✅ Virgin & Recycled Options – Injection Molding, Extrusion, Blow Molding, Compression Molding for Specialized Applications

✅ Excellent Chemical & Weather Resistance – Low-Temperature Flexibility for Optimal Performance Standards

✅ Multi-Industry Compatible – Enhanced Footwear, Packaging, Automotive & Industrial Properties

✅ Shoe Soles, Packaging Films, Hot Melt Adhesives & Automotive Components Applications

High-Quality Virgin/Recycled EVA Resin for Footwear Manufacturing, Packaging & Automotive Applications

Virgin/Recycled EVA Resin represents advanced copolymer technology specifically formulated for footwear manufacturing, flexible packaging applications, automotive components, and industrial operations requiring exceptional flexibility, chemical resistance, and multi-industry effectiveness. This essential ethylene vinyl acetate copolymer serves critical functions across shoe manufacturing, packaging systems, automotive parts, and specialized industrial applications requiring controlled elasticity, weather resistance, and processing capabilities with exceptional reliability.

At Chemicals & Process Equipment Limited, we supply high-performance Virgin/Recycled EVA Resins manufactured under stringent quality control standards and international industry specifications. Our comprehensive product range includes virgin grades, recycled formulations, specialty compounds, and custom blends meeting diverse requirements for footwear manufacturing, packaging applications, automotive components, and specialized industrial solutions across global footwear, packaging, automotive, and manufacturing markets.

✅ Advanced Copolymer Technology – Optimized Processing Properties & Multi-Industry Performance

✅ Consistent Quality Standards – Virgin & Recycled Grade Classifications with Comprehensive Documentation

✅ Essential Ethylene Vinyl Acetate Copolymer – Superior Footwear, Packaging & Automotive Performance

✅ Multi-Industry Applications – Footwear, Packaging, Automotive & Industrial Systems

✅ Technical Support Package – Complete Application Guidance & Performance Optimization

The global ethylene vinyl acetate market size was valued at USD 9.45 billion in 2024 and is projected to reach USD 12.7-16.67 billion by 2032-2037, growing at a CAGR of 2.3-5.7% during the forecast period, while the market is expected to reach 4.85 million tons in 2025 and grow at a CAGR of 5.02% to reach 6.20 million tons by 2030. This growth is driven by increasing footwear demand, expanding packaging applications, growing automotive requirements, and rising industrial applications across global manufacturing and consumer markets.

Technical Specifications & Virgin/Recycled EVA Resin Properties

| Property | Virgin Low VA (2-8%) | Virgin Medium VA (10-20%) | Virgin High VA (25-40%) | Recycled EVA Grade |

|---|---|---|---|---|

| Vinyl Acetate Content (%) | 2-8 | 10-20 | 25-40 | 8-25 |

| Density (g/cm³) | 0.920-0.935 | 0.935-0.950 | 0.950-0.970 | 0.930-0.960 |

| Melt Flow Index (g/10min) | 0.3-25 | 2-150 | 6-400 | 5-100 |

| Tensile Strength (MPa) | 10-20 | 8-15 | 5-12 | 6-15 |

| Elongation at Break (%) | 400-800 | 500-900 | 600-1000 | 400-800 |

| Flexural Modulus (MPa) | 50-200 | 30-100 | 10-50 | 20-150 |

| Impact Strength (kJ/m²) | No break | No break | No break | No break |

| Shore A Hardness | 85-95 | 70-90 | 50-80 | 60-90 |

| Melting Point (°C) | 90-105 | 75-95 | 60-85 | 70-100 |

| Glass Transition Temperature (°C) | -25 to -15 | -35 to -25 | -45 to -35 | -35 to -20 |

| Service Temperature (°C) | -40 to +80 | -50 to +70 | -60 to +60 | -45 to +75 |

| Thermal Conductivity (W/m·K) | 0.33-0.35 | 0.30-0.33 | 0.25-0.30 | 0.28-0.33 |

| Coefficient of Expansion (×10⁻⁵/°C) | 15-20 | 18-25 | 20-30 | 17-25 |

| Dielectric Strength (kV/mm) | 25-35 | 20-30 | 15-25 | 18-28 |

| Volume Resistivity (Ω·cm) | >10¹⁴ | >10¹³ | >10¹² | >10¹³ |

| Water Absorption (%) | <0.01 | <0.05 | <0.1 | <0.08 |

| Chemical Resistance | Excellent | Excellent | Good | Good-Excellent |

| UV Resistance | Good | Good | Fair | Good |

| Transparency | Transparent | Translucent | Opaque | Translucent |

| Processing Method | Extrusion, injection molding, compression molding | |||

| Crystallinity (%) | 40-55 | 25-45 | 10-30 | 20-45 |

| Processing Temperature (°C) | 150-220 | 140-200 | 120-180 | 130-200 |

| Mold Temperature (°C) | 20-60 | 20-50 | 20-40 | 20-55 |

| Injection Pressure (MPa) | 50-120 | 40-100 | 30-80 | 40-110 |

| Screw Speed (rpm) | 50-200 | 40-180 | 30-150 | 40-180 |

| Drying Required | Minimal | Minimal | Minimal | Yes (2-4 hours at 60°C) |

| Storage Conditions | Cool, dry environment | |||

| Shelf Life | 60 months (virgin), 36 months (recycled) | |||

| Packaging Options | 25kg bags, octabins, bulk containers |

Available Grade Types:

- Virgin Low VA Grade (2-8%) for rigid applications

- Virgin Medium VA Grade (10-20%) for flexible applications

- Virgin High VA Grade (25-40%) for elastomeric applications

- Recycled EVA Grade for sustainable applications

- UV Stabilized Grades for outdoor applications

- Flame Retardant Grades for safety applications

- Anti-Static Grades for electronic applications

- Colored Grades for aesthetic applications

- Food Contact Grades for packaging applications

- Medical Grades for healthcare applications

- Crosslinkable Grades for enhanced performance

- Hot Melt Adhesive Grades for bonding applications

Specialized Processing Solutions:

- Injection molding for footwear soles and components

- Extrusion for films and sheets

- Blow molding for flexible containers

- Compression molding for gaskets and seals

- Foam molding for cushioning applications

- Calendering for flexible films

- Rotational molding for hollow products

- Hot melt processing for adhesives

Footwear & Sports Applications

Athletic Shoe Components Footwear manufacturers utilize Virgin/Recycled EVA Resin for running shoe midsoles, athletic footwear, and sports shoe components requiring footwear specifications. Sports companies employ EVA resins for cushioning systems, shock absorption, and performance footwear applications.

Casual & Fashion Footwear Shoe manufacturers use Virgin/Recycled EVA Resin for casual shoe soles, fashion footwear, and everyday shoe components requiring comfort specifications. Fashion companies employ EVA resins for lightweight soles, flexible footwear, and casual shoe applications.

Outdoor & Work Footwear Work boot manufacturers utilize Virgin/Recycled EVA Resin for safety footwear, outdoor boots, and industrial shoe components requiring work boot specifications. Safety companies employ EVA resins for protective soles, slip-resistant footwear, and work boot applications.

Children’s & Specialty Footwear Children’s shoe manufacturers use Virgin/Recycled EVA Resin for kids’ footwear, specialty shoes, and pediatric footwear requiring child safety specifications. Specialty companies employ EVA resins for therapeutic footwear, orthopedic shoes, and specialty footwear applications.

Packaging & Film Applications

Flexible Packaging Films Packaging manufacturers utilize Virgin/Recycled EVA Resin for stretch films, shrink wraps, and flexible packaging requiring packaging specifications. Film companies employ EVA resins for food packaging, barrier films, and flexible packaging applications.

Agricultural & Greenhouse Films Agricultural manufacturers use Virgin/Recycled EVA Resin for greenhouse covers, agricultural mulch films, and crop protection requiring agricultural specifications. Farming companies employ EVA resins for UV-resistant films, soil covers, and agricultural film applications.

Industrial & Construction Films Construction manufacturers utilize Virgin/Recycled EVA Resin for vapor barriers, protective films, and construction applications requiring building specifications. Industrial companies employ EVA resins for waterproof membranes, protective sheets, and construction film applications.

Medical & Pharmaceutical Packaging Medical packaging manufacturers use Virgin/Recycled EVA Resin for medical pouches, pharmaceutical packaging, and healthcare applications requiring medical packaging specifications. Healthcare companies employ EVA resins for sterile packaging, medical films, and pharmaceutical packaging applications.

Automotive & Transportation Applications

Interior Components & Trim Automotive manufacturers utilize Virgin/Recycled EVA Resin for dashboard components, interior trim, and cabin applications requiring automotive interior specifications. Vehicle companies employ EVA resins for soft-touch surfaces, interior panels, and automotive trim applications.

Sealing & Gasket Applications Automotive sealing manufacturers use Virgin/Recycled EVA Resin for weather stripping, gaskets, and sealing systems requiring automotive sealing specifications. Vehicle suppliers employ EVA resins for door seals, window gaskets, and sealing applications.

Wire & Cable Applications Cable manufacturers utilize Virgin/Recycled EVA Resin for wire insulation, cable jacketing, and electrical applications requiring electrical specifications. Electronics companies employ EVA resins for cable protection, wire covering, and electrical insulation applications.

Transportation & Marine Components Transportation manufacturers use Virgin/Recycled EVA Resin for marine applications, transportation components, and vehicle accessories requiring transportation specifications. Marine companies employ EVA resins for boat components, marine seals, and water-resistant applications.

Industrial & Manufacturing Applications

Adhesives & Hot Melt Systems Adhesive manufacturers utilize Virgin/Recycled EVA Resin for hot melt adhesives, bonding systems, and assembly applications requiring adhesive specifications. Industrial companies employ EVA resins for packaging adhesives, bookbinding, and hot melt applications.

Foam & Cushioning Products Foam manufacturers use Virgin/Recycled EVA Resin for protective foam, cushioning materials, and impact absorption requiring foam specifications. Packaging companies employ EVA resins for protective packaging, foam inserts, and cushioning applications.

Toys & Consumer Products Toy manufacturers utilize Virgin/Recycled EVA Resin for children’s toys, recreational products, and consumer goods requiring toy safety specifications. Consumer companies employ EVA resins for foam toys, craft materials, and recreational applications.

Solar Panel & Energy Applications Solar manufacturers use Virgin/Recycled EVA Resin for photovoltaic encapsulants, solar panel components, and energy applications requiring solar specifications. Energy companies employ EVA resins for module encapsulation, solar films, and renewable energy applications.

Quality Control & Testing Procedures

Comprehensive Quality Assurance Every production batch undergoes extensive testing to ensure compliance with industry standards, processing requirements, and international quality specifications. Our quality control laboratory employs advanced analytical techniques including thermal analysis, mechanical testing, and chemical resistance evaluation. EVA is a copolymer made of ethylene and vinyl acetate monomers with high flexibility, transparency, good low temperature flexibility, excellent thermal resistance, high friction coefficient, and high tensile strength, making it 30% lighter than PVC.

Quality assurance procedures include:

- Melt flow index testing using automated rheometer

- Density measurement using density gradient column

- Thermal analysis using DSC and TGA methods

- Mechanical property testing using universal testing machine

- Impact resistance testing using Charpy and Izod methods

- Chemical resistance testing using solvent immersion

- UV resistance testing using weatherometer

- Clarity and haze measurement using nephelometer

- Shore hardness testing using durometer

- Tensile and elongation testing using extensometer

- Flexural testing using three-point bending

- Compression testing using compression tester

- Processing performance evaluation using pilot equipment

- Contamination analysis using microscopy

- Recycled content verification using analytical methods

- Food contact compliance testing for packaging grades

Application Guidelines & Best Practices

Processing Guidelines Establish proper processing procedures for Virgin/Recycled EVA Resin including temperature control, screw design, and processing parameters for optimal product quality and production efficiency in footwear and packaging applications.

Recycling & Sustainability Methods Develop appropriate recycling procedures including contamination removal, reprocessing techniques, and quality maintenance for sustainable EVA applications and circular economy practices.

Storage & Handling Procedures Implement proper storage conditions including moisture protection, temperature control, and contamination prevention for maintaining EVA resin quality and processing performance throughout storage periods.

For comprehensive information about ethylene vinyl acetate properties, applications, and recyclability, you can reference this detailed guide on EVA resin characteristics which provides extensive coverage of EVA properties, advantages, industrial applications, and environmental considerations including recycling challenges and sustainability aspects.

Market Applications & Industry Trends

Footwear Industry Growth Expanding athletic footwear demand and growing comfort shoe markets drive continued growth in EVA applications for shoe soles, midsoles, and footwear components across global footwear operations.

Packaging Market Expansion Growing flexible packaging demand and expanding e-commerce markets support increased adoption of EVA for films, pouches, and packaging applications worldwide.

Automotive Development Expanding vehicle production and growing automotive complexity drive growth in EVA applications for interior components, sealing systems, and automotive parts.

Environmental & Regulatory Compliance

Recycling Standards & Sustainability Virgin/Recycled EVA Resins support circular economy principles through recycling programs, waste reduction initiatives, and sustainable manufacturing practices while meeting environmental guidelines.

Food Contact Standards & Safety Adherence to FDA food contact regulations, EU plastic regulations, and international food safety guidelines supports responsible use in packaging and food contact applications.

Industry Standards & Certifications Compliance with ASTM, ISO, and international standards ensures appropriate use in footwear, automotive, and industrial applications with quality and safety requirements.

Performance Advantages & Technical Benefits

✔ Superior Flexibility – Outstanding elasticity and flexibility at low temperatures

✔ Excellent Clarity – Crystal clear transparency for packaging applications

✔ Chemical Resistance – Resistance to oils, acids, and environmental chemicals

✔ Weather Resistance – Good UV stability and weathering resistance

✔ Low-Temperature Performance – Maintains flexibility down to -60°C

✔ Processing Versatility – Suitable for multiple processing methods

✔ Lightweight Properties – 30% lighter than PVC for weight-sensitive applications

✔ Impact Resistance – Excellent toughness and impact absorption

✔ Thermal Stability – Good heat resistance for processing and service

✔ Recyclability – Sustainable recycling options available

✔ Cost-Effective Solution – Economical alternative to specialty polymers

✔ Dimensional Stability – Low shrinkage and good dimensional control

Our Virgin/Recycled EVA Resin products represent industry-leading standards in copolymer technology and multi-industry solutions, specifically formulated for demanding footwear operations, packaging applications, automotive components, and specialized industrial applications. We provide comprehensive technical support, processing guidance, and application consultation to ensure optimal performance across your specialized footwear, packaging, automotive, or industrial applications.

For detailed specifications, technical data sheets, or application-specific recommendations, contact our specialized polymer materials division. We offer complete support including processing optimization, equipment recommendations, and technical guidance to maximize effectiveness in your footwear, packaging, automotive, or industrial applications.

For more information about our products, feel free to Contact Us today.

Reviews

There are no reviews yet.