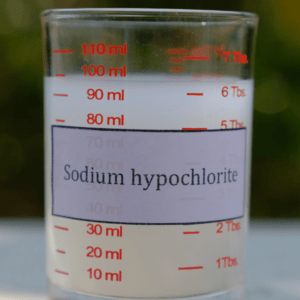

SODIUM HYPOCHLORITE

Sodium Hypochlorite (NaOCl)

✅ Superior Disinfecting Power – Chlorine-Based Chemistry with Excellent Antimicrobial Performance

✅ Multiple Concentration Options – 5.25%, 10%, 12.5%, 15% and Custom Grades Available

✅ Excellent Functional Properties – Broad Spectrum Biocide, Oxidizing Agent, Bleaching Power

✅ Multi-Industry Compatible – Enhanced Water Treatment, Food Processing & Industrial Applications

✅ NSF Certified Solutions – Certified Chemistry Supporting Safe Water Treatment Applications

High-Quality Sodium Hypochlorite

Sodium Hypochlorite (NaOCl), chemically formulated as an aqueous solution with molecular weight 74.44 g/mol, CAS number 7681-52-9, and available chlorine content typically 10-15%, is a powerful oxidizing and disinfecting agent produced by reacting chlorine gas with sodium hydroxide solution under controlled conditions. This pale yellow-green liquid with a characteristic chlorine odor is widely used in waterworks for chlorination of water at 12% concentration, with 15% solutions commonly used for wastewater disinfection in treatment plants, and demonstrates exceptional antimicrobial efficacy against bacteria, viruses, fungi, and other microorganisms. Sodium hypochlorite solutions are made by reacting chlorine (gas or liquid) with dilute sodium hydroxide solution and are commonly available in strengths of 3 to 20 wt.% sodium hypochlorite. With outstanding properties including rapid kill times, broad spectrum antimicrobial activity, effective organic matter oxidation, excellent bleaching capability, and proven disinfection reliability, sodium hypochlorite provides critical performance in municipal water systems, industrial processes, healthcare facilities, food processing operations, and specialized applications requiring effective pathogen control and chemical oxidation with established safety profiles and regulatory compliance.

At Chemicals & Process Equipment Limited, we supply high-performance Sodium Hypochlorite manufactured under stringent quality control standards and international water treatment, food safety, and industrial specifications. Our comprehensive product range includes various concentration levels, stabilized formulations, and specialized grades meeting diverse requirements for municipal water treatment, industrial disinfection, food processing sanitization, and specialized applications across global water utility, healthcare, food processing, and industrial markets.

✅ Advanced Disinfection Technology – Optimized Chemistry & Multi-Application Performance

✅ Consistent Quality Standards – NSF Certified with Comprehensive Documentation

✅ Essential Water Treatment Chemical – Superior Municipal, Industrial & Healthcare Performance

✅ Multi-Industry Applications – Water Treatment, Food Processing, Healthcare & Industrial Systems

✅ Technical Support Package – Complete Application Guidance & Performance Optimization

The global sodium hypochlorite market was valued at approximately USD 3.8 billion in 2023 and is projected to reach USD 5.2 billion by 2030, growing at a CAGR of 4.6% during the forecast period. Market expansion is driven by increasing water treatment demand, growing healthcare disinfection requirements, expanding food processing applications, rising industrial cleaning needs, and applications requiring effective pathogen control and chemical oxidation.

Technical Specifications & Sodium Hypochlorite Properties

| Property | Municipal Grade | Industrial Grade | Food Grade | Healthcare Grade | Household Grade | Technical Grade |

|---|---|---|---|---|---|---|

| Available Chlorine (%) | 12.0-15.0 | 10.0-20.0 | 5.25-6.0 | 5.25-10.0 | 3.0-8.0 | 5.0-50.0 |

| Sodium Hypochlorite (%) | 12.5-15.6 | 10.4-20.8 | 5.46-6.24 | 5.46-10.4 | 3.12-8.32 | 5.2-52.0 |

| Total Alkalinity (as NaOH) (%) | 0.1-1.0 | 0.1-2.0 | 0.01-0.05 | 0.01-0.1 | 0.01-0.05 | 0.1-3.0 |

| Free Caustic (as NaOH) (%) | 0.01-0.10 | 0.01-0.20 | ≤0.01 | ≤0.01 | ≤0.01 | 0.01-0.50 |

| Sodium Carbonate (%) | ≤0.5 | ≤1.0 | ≤0.1 | ≤0.2 | ≤0.1 | ≤2.0 |

| Sodium Chloride (%) | ≤1.0 | ≤2.0 | ≤0.5 | ≤0.8 | ≤0.5 | ≤5.0 |

| Sodium Chlorate (ppm) | ≤1000 | ≤2000 | ≤200 | ≤500 | ≤200 | ≤5000 |

| pH (as supplied) | 11.0-13.0 | 11.0-13.5 | 11.0-12.5 | 11.0-12.5 | 11.0-12.5 | 10.5-14.0 |

| Specific Gravity (20°C) | 1.15-1.25 | 1.10-1.35 | 1.05-1.10 | 1.05-1.15 | 1.03-1.08 | 1.05-1.45 |

| Iron (as Fe) (ppm) | ≤5 | ≤10 | ≤2 | ≤3 | ≤2 | ≤20 |

| Nickel (as Ni) (ppm) | ≤2 | ≤5 | ≤1 | ≤1 | ≤1 | ≤10 |

| Heavy Metals (as Pb) (ppm) | ≤10 | ≤20 | ≤5 | ≤5 | ≤5 | ≤50 |

| Arsenic (as As) (ppm) | ≤10 | ≤20 | ≤5 | ≤5 | ≤5 | ≤50 |

| Mercury (as Hg) (ppm) | ≤1 | ≤2 | ≤0.5 | ≤0.5 | ≤0.5 | ≤5 |

| Bromate (as BrO₃) (ppm) | ≤100 | ≤200 | ≤50 | ≤50 | ≤50 | ≤500 |

| Turbidity (NTU) | ≤5 | ≤10 | ≤2 | ≤3 | ≤2 | ≤20 |

| Color (APHA) | ≤50 | ≤100 | ≤25 | ≤30 | ≤25 | ≤200 |

| Odor Threshold Number | ≤8 | ≤15 | ≤4 | ≤6 | ≤4 | ≤25 |

| Residual Free Chlorine (ppm) | Variable | Variable | Variable | Variable | Variable | Variable |

| Contact Time (CT) Value | High | High | High | High | Medium | Variable |

| Biocidal Efficacy | Excellent | Excellent | Excellent | Excellent | Good | Variable |

| Oxidizing Potential (mV) | +800 to +1000 | +800 to +1000 | +800 to +1000 | +800 to +1000 | +750 to +950 | +700 to +1100 |

| Decomposition Rate (%/month) | ≤10 | ≤15 | ≤8 | ≤10 | ≤8 | ≤20 |

| Stability (at 20°C) | Good | Good | Excellent | Excellent | Good | Fair |

| Freeze Point (°C) | -15 to -25 | -10 to -30 | -5 to -15 | -5 to -20 | -2 to -10 | -5 to -35 |

| Corrosivity | Moderate | High | Low | Low | Low | Variable |

| Material Compatibility | Limited | Limited | Good | Good | Good | Poor |

| Foam Generation | Low | Medium | Low | Low | Low | Variable |

| Chlorine Demand (ppm) | Variable | Variable | Low | Low | Low | Variable |

| Breakthrough Time | 15-30 min | 10-60 min | 5-15 min | 5-20 min | 2-10 min | Variable |

| Log Reduction (bacteria) | >6 | >6 | >4 | >5 | >3 | Variable |

| Log Reduction (viruses) | >4 | >4 | >3 | >4 | >2 | Variable |

| Log Reduction (spores) | >3 | >3 | >2 | >3 | >1 | Variable |

| Packaging Compatibility | HDPE/FRP | HDPE/FRP | HDPE | HDPE | HDPE/Glass | Various |

| Storage Temperature (°C) | 5-25 | 0-30 | 10-25 | 10-25 | 15-25 | 0-35 |

| Shelf Life (months) | 6-12 | 3-12 | 12-24 | 6-18 | 12-24 | 3-18 |

| NSF Certification | Yes | Limited | Yes | Yes | Yes | No |

| EPA Registration | Required | Required | Required | Required | Limited | Variable |

| CAS Number | 7681-52-9 | 7681-52-9 | 7681-52-9 | 7681-52-9 | 7681-52-9 | 7681-52-9 |

| EINECS Number | 231-668-3 | 231-668-3 | 231-668-3 | 231-668-3 | 231-668-3 | 231-668-3 |

| UN Number | 1791 | 1791 | 1791 | 1791 | 1791 | 1791 |

| Hazard Class | 8 (Corrosive) | 8 (Corrosive) | 8 (Corrosive) | 8 (Corrosive) | 8 (Corrosive) | 8 (Corrosive) |

| Packaging Group | II/III | II/III | III | III | III | II/III |

Available Grade Classifications:

- Municipal Grade (NSF 60) for drinking water treatment and public water systems

- Industrial Grade for industrial water treatment and process applications

- Food Grade (NSF 60) for food processing and contact surface sanitization

- Healthcare Grade for hospital and medical facility disinfection

- Household Grade for consumer cleaning and disinfection products

- Technical Grade for specialized industrial and research applications

- Swimming Pool Grade for recreational water treatment and sanitization

- Laundry Grade for commercial laundry bleaching and sanitization

- Pulp & Paper Grade for bleaching and oxidation processes

- Textile Grade for fabric bleaching and processing

- High Concentration Grade (up to 50%) for specialized applications

- Stabilized Grade with enhanced storage stability and shelf life

Specialized Processing Solutions:

- Concentration optimization for specific applications

- pH adjustment and stabilization services

- Corrosion inhibitor addition for equipment protection

- Quality testing and certification programs

- On-site generation system support

- Application development and dosing optimization

- Technical consultation and system design assistance

- Regulatory compliance and documentation support

Municipal Water Treatment Applications

Drinking Water Disinfection Water utilities utilize Sodium Hypochlorite for primary disinfection, secondary disinfection, and distribution system maintenance requiring municipal specifications. Water treatment facilities employ 12% sodium hypochlorite solutions for chlorination of water to prevent transmission of waterborne diseases such as cholera and typhoid, providing effective pathogen elimination, residual chlorine maintenance, and water safety assurance with proven disinfection reliability.

Wastewater Treatment Operations Wastewater treatment plants use Sodium Hypochlorite for effluent disinfection, process water treatment, and facility sanitization requiring wastewater specifications. Treatment facilities employ 15% sodium hypochlorite solutions for disinfection of wastewater in treatment plants, ensuring pathogen destruction, regulatory compliance, and environmental protection with established treatment protocols.

Swimming Pool & Recreational Water Treatment Pool operators utilize Sodium Hypochlorite for primary sanitization, shock treatment, and water quality maintenance requiring recreational water specifications. Aquatic facilities employ sodium hypochlorite for pathogen control, algae prevention, and swimmer safety applications requiring effective sanitization and water clarity.

Industrial Water Treatment Applications

Cooling Water Systems Industrial facilities utilize Sodium Hypochlorite for cooling tower treatment, heat exchanger cleaning, and biofouling control requiring industrial specifications. Manufacturing companies employ sodium hypochlorite for microbial control, biofilm prevention, and cooling system applications requiring heat transfer efficiency and equipment protection.

Boiler Water Treatment Power generation and industrial facilities use Sodium Hypochlorite for boiler feedwater treatment, steam system disinfection, and process water conditioning requiring boiler specifications. Utility companies employ sodium hypochlorite for scale prevention, corrosion control, and steam applications requiring system reliability and efficiency.

Process Water Disinfection Manufacturing facilities utilize Sodium Hypochlorite for process water treatment, equipment sanitization, and production water quality requiring process specifications. Industrial companies employ sodium hypochlorite for contamination prevention, product quality assurance, and manufacturing applications requiring consistent water quality and safety.

Food & Beverage Industry Applications

Food Processing Sanitization Food manufacturers utilize Sodium Hypochlorite for equipment sanitization, surface disinfection, and food contact area cleaning requiring food processing specifications. Food companies employ sodium hypochlorite for pathogen elimination, cross-contamination prevention, and food safety applications requiring HACCP compliance and regulatory approval.

Beverage Production Water Treatment Beverage manufacturers use Sodium Hypochlorite for process water treatment, equipment cleaning, and facility sanitization requiring beverage specifications. Bottling companies employ sodium hypochlorite for water quality assurance, product safety, and beverage applications requiring taste and odor control with microbiological safety.

Produce Washing & Sanitization Agricultural processors utilize Sodium Hypochlorite for fruit and vegetable washing, post-harvest treatment, and packaging sanitization requiring produce specifications. Fresh food companies employ sodium hypochlorite for pathogen reduction, shelf life extension, and produce applications requiring food safety and quality maintenance.

Healthcare Facility Applications

Hospital Disinfection Systems Healthcare facilities utilize Sodium Hypochlorite for surface disinfection, equipment cleaning, and facility-wide sanitization requiring healthcare specifications. Hospitals employ sodium hypochlorite solutions for killing germs when properly diluted, with appropriate personal protective equipment required when preparing and using hypochlorite solutions, providing broad spectrum antimicrobial activity, healthcare-associated infection prevention, and patient safety assurance.

Medical Equipment Sterilization Medical device processing facilities use Sodium Hypochlorite for instrument disinfection, endoscope reprocessing, and device sanitization requiring medical specifications. Healthcare providers employ sodium hypochlorite for high-level disinfection, biofilm removal, and medical applications requiring sterility assurance and infection control.

Laboratory Disinfection Clinical laboratories utilize Sodium Hypochlorite for work surface disinfection, spill cleanup, and contamination control requiring laboratory specifications. Laboratory facilities employ 10% bleach (sodium hypochlorite) to disinfect benches before and after work, and when spills occur, ensuring laboratory safety, sample integrity, and personnel protection with established disinfection protocols.

Industrial Bleaching Applications

Textile Bleaching Operations Textile manufacturers utilize Sodium Hypochlorite for fabric bleaching, color removal, and textile processing requiring textile specifications. Textile companies employ sodium hypochlorite for whiteness enhancement, stain removal, and textile applications requiring color consistency and fabric quality with minimal fiber damage.

Pulp & Paper Bleaching Paper manufacturers use Sodium Hypochlorite for pulp bleaching, brightness enhancement, and paper processing requiring pulp specifications. Paper companies employ sodium hypochlorite for lignin removal, brightness development, and paper applications requiring optical properties and strength retention.

Laundry & Commercial Cleaning Commercial laundries utilize Sodium Hypochlorite for fabric sanitization, stain removal, and commercial washing requiring laundry specifications. Cleaning companies employ sodium hypochlorite for soil removal, whiteness restoration, and laundry applications requiring fabric care and hygiene maintenance.

Specialized Industrial Applications

Chemical Manufacturing Processes Chemical manufacturers utilize Sodium Hypochlorite for oxidation reactions, intermediate synthesis, and process chemistry requiring chemical specifications. Specialty chemical companies employ sodium hypochlorite for organic synthesis, waste treatment, and chemical applications requiring controlled oxidation and reaction selectivity.

Oil & Gas Industry Applications Petroleum companies use Sodium Hypochlorite for produced water treatment, hydrogen sulfide removal, and facility sanitization requiring oil and gas specifications. Energy companies employ sodium hypochlorite for biocide treatment, corrosion control, and oil field applications requiring system protection and environmental compliance.

Mining & Mineral Processing Mining operations utilize Sodium Hypochlorite for process water treatment, tailings management, and facility disinfection requiring mining specifications. Mineral processing companies employ sodium hypochlorite for cyanide destruction, metal recovery, and mining applications requiring environmental protection and safety compliance.

Quality Control & Testing Procedures

Comprehensive Quality Assurance Every production batch undergoes extensive testing to ensure compliance with water treatment standards, food safety requirements, healthcare disinfection specifications, and international quality guidelines. Our quality control laboratory employs advanced analytical techniques including available chlorine analysis, microbial efficacy testing, and comprehensive chemical characterization.

Quality assurance procedures include:

- Available chlorine determination using iodometric titration

- Sodium hypochlorite content analysis using standard methods

- Total alkalinity measurement using acid titration

- Free caustic determination using phenolphthalein endpoint

- Sodium carbonate analysis using carbonate-specific methods

- Sodium chloride content testing using argentometric titration

- Sodium chlorate analysis using ion chromatography

- pH measurement using calibrated electrode systems

- Specific gravity determination using hydrometer methods

- Iron content testing using colorimetric analysis

- Nickel analysis using atomic absorption spectroscopy

- Heavy metals screening using ICP-MS techniques

- Arsenic determination using hydride generation AAS

- Mercury content analysis using cold vapor techniques

- Bromate testing using ion chromatography methods

- Turbidity measurement using nephelometric methods

- Color analysis using spectrophotometric techniques

- Odor threshold testing using sensory evaluation

- Decomposition rate monitoring using accelerated aging

- Stability testing under various storage conditions

- Microbiological efficacy evaluation using standard organisms

- Contact time (CT) value determination

- Oxidizing potential measurement using redox electrodes

- Corrosivity assessment using material exposure tests

- Foam generation testing using standardized methods

- Chlorine demand analysis using breakpoint procedures

- Log reduction verification using challenge testing

- NSF compliance verification for certified grades

- EPA registration support and documentation

- Packaging compatibility testing using container materials

- Shelf life determination using stability studies

- Environmental fate and transport analysis

- Toxicological assessment and safety evaluation

- Regulatory compliance verification programs

- Quality consistency monitoring using statistical methods

Storage & Handling Procedures Implement proper storage conditions including temperature control between 5-25°C, protection from light and heat, appropriate container materials (HDPE/FRP), and proper ventilation for maintaining Sodium Hypochlorite quality and preventing decomposition throughout storage periods.

For comprehensive information about sodium hypochlorite applications, water treatment guidelines, and disinfection protocols, you can reference this detailed CDC guidance on cleaning and disinfecting with bleach which provides extensive coverage of safe use practices, dilution procedures, and effectiveness against pathogens across various applications.

Market Applications & Industry Trends

Water Treatment Industry Growth Expanding urban populations, increasing water quality regulations, and growing infrastructure development drive significant growth in sodium hypochlorite consumption for municipal water treatment, industrial process water, and specialized water treatment applications requiring reliable disinfection technology.

Healthcare Disinfection Demand Growing healthcare sector, increasing infection control requirements, and expanding medical facility construction support growth in sodium hypochlorite applications for hospital disinfection, medical device processing, and healthcare facility sanitization requiring proven antimicrobial efficacy.

Food Safety Regulations Expansion Developing food safety standards, increasing regulatory compliance requirements, and growing consumer awareness drive adoption of sodium hypochlorite for food processing sanitization, produce washing, and food contact surface disinfection requiring microbiological safety assurance.

Industrial Process Applications Expanding chemical manufacturing, growing textile processing, and increasing industrial cleaning applications support growth in sodium hypochlorite applications for bleaching operations, process chemistry, and industrial sanitization requiring effective oxidation and disinfection capabilities.

Environmental & Regulatory Compliance

Water Treatment Standards & Certifications Sodium Hypochlorite complies with NSF/ANSI 60 standards for drinking water treatment chemicals, EPA regulations for disinfectant use, and international water quality guidelines ensuring safe use in water treatment applications with established residual limits and comprehensive toxicological evaluations.

Food Safety Compliance Standards Adherence to FDA food contact regulations, USDA sanitizer guidelines, and international food safety standards supports safe use in food processing applications with established maximum residue levels and comprehensive food safety assessments.

Healthcare Disinfection Standards Compliance with CDC disinfection guidelines, EPA hospital disinfectant regulations, and international healthcare standards ensures appropriate use in healthcare applications with established efficacy requirements and safety protocols for healthcare personnel.

Environmental Protection Standards Environmental compliance includes discharge regulations, air emission standards, and waste management guidelines ensuring minimal environmental impact through proper use and disposal practices supporting aquatic life protection and environmental safety.

Performance Advantages & Technical Benefits

✔ Broad Spectrum Antimicrobial Activity – Effective against bacteria, viruses, fungi, and spores

✔ Rapid Kill Times – Fast-acting biocidal performance for efficient disinfection

✔ Proven Efficacy – Decades of successful use in critical applications

✔ Cost Effective Disinfection – Economical solution for large-scale applications

✔ Residual Protection – Maintains disinfection throughout distribution systems

✔ Easy Application – Simple dosing and monitoring procedures

✔ Regulatory Approved – NSF certified and EPA registered formulations

✔ Versatile Chemistry – Suitable for diverse disinfection applications

✔ Measurable Residuals – Easy monitoring and control capabilities

✔ No Harmful By-products – Decomposes to harmless salt and water

✔ Temperature Stable – Effective across normal operating temperatures

✔ pH Flexible – Functions across wide pH ranges

✔ Quality Consistent – Reliable performance across production batches

✔ Technical Support – Complete application guidance and system design

✔ Global Availability – Worldwide supply and technical support network

✔ Safety Established – Extensive toxicological database and safety protocols

Our Sodium Hypochlorite products represent industry-leading standards in disinfection chemistry and multi-application performance, specifically selected for demanding water treatment operations, healthcare disinfection, food processing sanitization, and specialized industrial applications requiring exceptional antimicrobial efficacy, chemical oxidation capability, and regulatory compliance. We provide comprehensive technical support, application guidance, and system design consultation to ensure optimal performance across your specialized water treatment, healthcare, food processing, or industrial disinfection applications.

For detailed specifications, technical data sheets, or application-specific recommendations, contact our specialized water treatment chemicals division. We offer complete support including system design optimization, regulatory compliance assistance, and technical support to maximize effectiveness in your water treatment, healthcare, food processing, or industrial applications.

For more information about our products, feel free to Contact Us today.

Reviews

There are no reviews yet.