PHOSPHORIC ACID 85%

PHOSPHORIC ACID 85% – Advanced Chemical Processing & Food Grade Applications

Professional Phosphoric Acid 85% H3PO4 – High-Performance Mineral Acid, Food Acidulant, Metal Surface Treatment Agent, Fertilizer Component, Rust Removal Solution, pH Adjustment Chemical, Water Treatment Compound & Specialized Inorganic Acid for Industrial Processing, Food Manufacturing, Agricultural Applications, Metal Treatment, Chemical Synthesis & Advanced Acidification Technology

✅ Premium Food Grade – Superior Acidification & Food Processing Excellence

✅ Industrial Quality Proven – Outstanding Metal Treatment & Surface Preparation Benefits

✅ Agricultural Compatible – Exceptional Fertilizer & Nutrient Enhancement Properties

✅ Water Treatment Effective – Superior pH Control & Scale Prevention Enhancement

✅ Quality Assured – High Purity, Low Impurities & Global Standards Compliance Worldwide

Phosphoric Acid 85% – Industrial & Food Processing Applications

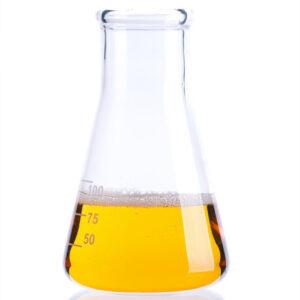

Phosphoric Acid 85% H3PO4, featuring molecular weight 97.99 g/mol with exceptional acidification characteristics, appearing as clear colorless liquid with outstanding water miscibility, superior chemical reactivity properties, and exceptional versatility across diverse industrial applications, is a specialized high-performance mineral acid with outstanding performance characteristics, enhanced processing efficiency, and superior functionality in food acidification, metal surface treatment, fertilizer production, water treatment systems, chemical synthesis, and specialized industrial processing. Phosphoric Acid 85% is a high-performance mineral acid extensively used for food processing, metal treatment, fertilizer manufacturing, and specialized chemical applications. H3PO4 is a high purity, highly concentrated inorganic acid with excellent acidifying properties used for pH adjustment, surface preparation, nutrient solutions, and industrial processes. The global phosphoric acid market size was valued at USD 45.2 billion in 2024 and is expected to reach USD 58.7 billion by 2032, at a CAGR of 3.3% during the forecast period, with modern industrial applications expanding significantly for food processing and agricultural industries. The compound exhibits exceptional acidifying characteristics and provides superior chemical reactivity making it ideal for metal treatment applications, food processing operations, fertilizer formulations, and specialized industrial processes. Phosphoric Acid 85% is specifically processed to provide enhanced acidification efficiency, improved processing performance, and superior results in applications requiring effective pH control, reliable metal surface preparation, controlled chemical reactions, and industrial-grade performance in food processing, metal treatment, agricultural, and specialized applications. In addition to its acidifying properties, it also has excellent chelating characteristics and controlled corrosion properties. The nature of Phosphoric Acid 85% is chemically stable with moderate corrosivity and excellent solubility, making it function as one of the most versatile mineral acids available, being highly effective and providing excellent acidification properties, delivering broad-spectrum industrial applications, effective food processing performance, excellent process compatibility under various conditions, and outstanding safety profile during proper handling and application. Phosphoric Acid 85% represents one of the most essential and versatile inorganic compounds in modern industrial processing, food manufacturing, agricultural production, and specialized chemical sectors, providing exceptional acidification properties, superior processing characteristics, excellent chemical reactivity, and outstanding regulatory compliance during manufacturing and application, making it essential for food processing operations, metal treatment facilities, fertilizer production, water treatment systems, and specialized processes requiring high-performance mineral acid chemistry and regulatory approval with international food safety and industrial standards.

At Chemicals & Process Equipment Limited, we supply advanced Phosphoric Acid 85% manufactured under stringent quality control standards and international chemical, food grade, industrial, and technical specifications. Our comprehensive product range includes various concentration levels, different purity grades, and specialized formulations meeting diverse requirements for food processing operations, industrial facilities, agricultural applications, metal treatment processes, and specialized applications across global food, agricultural, industrial, and chemical markets.

✅ Advanced Mineral Acid Technology – Optimized Performance & Processing Excellence

✅ Consistent Quality Standards – Multiple Product Classifications with Complete Documentation

✅ Essential Processing Component – Superior Acidification Properties & Industrial Compatibility

✅ Multi-Industry Applications – Food, Industrial, Agricultural, Metal Treatment Industries

✅ Technical Support Package – Complete Application Guidance & Performance Optimization

In 2024, the fertilizer sector commanded a substantial 68% share of the market revenue. Leading the charge, diammonium phosphate (DAP) and monoammonium phosphate (MAP) production took the spotlight, closely trailed by food processing applications that require precise pH control and acidification for beverage and processed food manufacturing. Market expansion is driven by increasing agricultural demand, growing food processing industry, expanding fertilizer production capacity, and rising industrial processing requirements across multiple manufacturing regions.

For comprehensive information about phosphoric acid applications in food technology and industrial processing, this detailed technical resource from the FDA on phosphoric acid in food processing provides extensive coverage of mineral acid properties, regulatory requirements, and safety guidelines for modern food and industrial applications.

Technical Specifications & Properties

| Property | Food Grade | Industrial Grade | Agricultural Grade | Technical Grade | Reagent Grade | Electronic Grade |

|---|---|---|---|---|---|---|

| H3PO4 Content (%) | 85.0-86.0 | 85.0-87.0 | 84.0-86.0 | 83.0-87.0 | 85.0-85.5 | 85.0-85.2 |

| Purity (%) | 99.5-100.0 | 98.0-99.5 | 97.0-99.0 | 95.0-98.0 | 99.8-100.0 | 99.9-100.0 |

| Specific Gravity (20°C) | 1.689-1.695 | 1.685-1.700 | 1.680-1.700 | 1.675-1.705 | 1.690-1.694 | 1.689-1.693 |

| Density (g/cm³) | 1.689-1.695 | 1.685-1.700 | 1.680-1.700 | 1.675-1.705 | 1.690-1.694 | 1.689-1.693 |

| Arsenic (As) Content (ppm) | <0.5 | <3 | <5 | <10 | <0.1 | <0.05 |

| Lead (Pb) Content (ppm) | <1 | <5 | <10 | <20 | <0.5 | <0.1 |

| Iron (Fe) Content (ppm) | <10 | <50 | <100 | <200 | <5 | <2 |

| Chloride (Cl) Content (ppm) | <10 | <50 | <100 | <200 | <5 | <2 |

| Sulfate (SO4) Content (ppm) | <50 | <200 | <500 | <1000 | <20 | <10 |

| Heavy Metals (ppm) | <10 | <50 | <100 | <200 | <5 | <2 |

| Fluoride (F) Content (ppm) | <10 | <25 | <50 | <100 | <5 | <2 |

| Water Content (%) | 14.0-15.0 | 13.0-15.0 | 14.0-16.0 | 13.0-17.0 | 14.5-15.0 | 14.8-15.2 |

| Color (APHA) | <20 | <50 | <100 | <200 | <10 | <5 |

| pH (1% solution) | 1.5-2.0 | 1.0-2.5 | 1.0-2.5 | 0.5-3.0 | 1.8-2.0 | 1.9-2.0 |

| Boiling Point (°C) | 213 | 213 | 213 | 213 | 213 | 213 |

| Freezing Point (°C) | 21 | 20-22 | 19-23 | 18-24 | 21 | 21 |

| Viscosity (cP, 20°C) | 147 | 140-155 | 135-160 | 130-165 | 145-150 | 146-149 |

| Electrical Conductivity (mS/cm) | 590-610 | 580-620 | 570-630 | 550-650 | 595-605 | 598-602 |

| Reducing Substances (%) | <0.01 | <0.05 | <0.1 | <0.2 | <0.005 | <0.001 |

| Oxidizing Substances (%) | <0.01 | <0.05 | <0.1 | <0.2 | <0.005 | <0.001 |

| Copper (Cu) Content (ppm) | <2 | <10 | <20 | <50 | <1 | <0.5 |

| Zinc (Zn) Content (ppm) | <5 | <25 | <50 | <100 | <2 | <1 |

| Calcium (Ca) Content (ppm) | <20 | <100 | <200 | <500 | <10 | <5 |

| Magnesium (Mg) Content (ppm) | <10 | <50 | <100 | <200 | <5 | <2 |

| Aluminum (Al) Content (ppm) | <5 | <25 | <50 | <100 | <2 | <1 |

| Chromium (Cr) Content (ppm) | <1 | <5 | <10 | <20 | <0.5 | <0.2 |

| Nickel (Ni) Content (ppm) | <2 | <10 | <20 | <50 | <1 | <0.5 |

| Appearance | Clear Liquid | Clear Liquid | Clear Liquid | Clear/Slightly Hazy | Clear Liquid | Crystal Clear |

| Odor | Odorless | Odorless | Slight Acidic | Slight Acidic | Odorless | Odorless |

| Crystallization Tendency | Low | Low | Low | Moderate | Very Low | Very Low |

| Storage Stability (months) | 24 | 36 | 24 | 18 | 24 | 18 |

| Storage Temperature (°C) | 15-35 | 10-40 | 5-45 | 0-50 | 15-30 | 20-25 |

| Container Compatibility | SS/HDPE/Glass | SS/HDPE | SS/HDPE/FRP | Steel/HDPE | Glass/PTFE | Glass/PTFE |

| Corrosivity Level | Moderate | Moderate | Moderate | High | Low | Very Low |

| Environmental Impact | Low | Low | Low | Moderate | Very Low | Very Low |

| Biodegradability | Good | Good | Good | Fair | Excellent | Excellent |

| Toxicity Level | Low | Low | Low | Moderate | Very Low | Very Low |

| Packaging | 35kg Drums | 300kg IBCs | 1000kg IBCs | Bulk Tanks | 2.5kg Bottles | 1kg Bottles |

| Regulatory Status | FDA/FCC | Industrial | Agricultural | Technical | ACS/Reagent | Semiconductor |

Available Product Types:

- Food Grade for beverage and food processing applications

- Industrial Grade for metal treatment and chemical processing

- Agricultural Grade for fertilizer production and soil amendment

- Technical Grade for general industrial and manufacturing processes

- Reagent Grade for laboratory and analytical applications

- Electronic Grade for semiconductor and electronics manufacturing

- Pharmaceutical Grade for drug manufacturing and medical applications

- Water Treatment Grade for municipal and industrial water systems

- Fertilizer Grade for phosphate fertilizer production

- Metal Treatment Grade for surface preparation and rust removal

- Rust Removal Grade for specialized cleaning applications

- pH Control Grade for water treatment and chemical processing

- Custom Specifications for unique manufacturing requirements

- High Purity Grade for specialized analytical and research uses

- Concentrated Grade for specific industrial applications

Specialized Application Solutions:

- Food processing optimization and pH control system design

- Metal treatment consultation and surface preparation protocols

- Fertilizer formulation development and nutrient enhancement

- Water treatment system design and pH management

- Quality control method development and testing procedures

- Regulatory compliance assistance and safety assessment

- Custom phosphoric acid development and performance testing services

- Technical consultation and process optimization

- Chemical synthesis consulting and reaction optimization

Food & Beverage Applications

Beverage Processing Beverage manufacturers utilize Food Grade Phosphoric Acid 85% H3PO4 as premium acidulant for cola drinks, soft beverages, and flavored products. Food technologists employing H3PO4 for enhanced flavor profile, effective pH control, and processing optimization providing superior beverage products, excellent taste performance, and outstanding food productivity with complete acidification optimization.

Food Preservation Food processing companies use specialized Phosphoric Acid formulations for preservation systems, antimicrobial enhancement, and shelf-life improvement. Food preservation specialists employ H3PO4 for enhanced microbial control, improved food safety, and preservation optimization providing improved food storage outcomes, enhanced product stability, and superior food manufacturing performance.

Dairy Processing Dairy manufacturers utilize Food Grade Phosphoric Acid for cheese production, dairy processing, and product enhancement. Dairy specialists employ H3PO4 for enhanced protein coagulation, improved texture development, and dairy optimization providing exceptional dairy results, enhanced product quality, and outstanding dairy manufacturing performance.

Processed Foods Food companies use Food Grade Phosphoric Acid for processed food production, flavor enhancement, and food improvement. Food processing specialists employ H3PO4 for enhanced taste balance, improved product stability, and food optimization providing exceptional processed food results, enhanced flavor quality, and superior food manufacturing excellence.

Industrial & Metal Treatment Applications

Metal Surface Treatment Metal processing manufacturers utilize Industrial Grade Phosphoric Acid 85% H3PO4 for rust removal, surface preparation, and metal enhancement. Metal treatment engineers employ H3PO4 for enhanced surface cleaning, improved coating adhesion, and metal optimization providing superior metal products, enhanced surface quality, and outstanding metal processing results.

Rust Removal Systems Rust removal companies use specialized Phosphoric Acid for corrosion control, metal restoration, and surface improvement. Rust treatment specialists employ H3PO4 for enhanced rust conversion, improved surface preparation, and metal optimization providing exceptional rust removal results, enhanced metal restoration, and superior surface treatment excellence.

Steel Processing Steel manufacturers utilize Industrial Grade Phosphoric Acid for steel treatment, surface enhancement, and metal improvement. Steel processing engineers employ H3PO4 for enhanced surface preparation, improved steel quality, and processing optimization providing superior steel products, enhanced metal properties, and outstanding steel manufacturing results.

Electroplating Operations Electroplating companies use Industrial Grade Phosphoric Acid for surface preparation, plating enhancement, and metal improvement. Electroplating specialists employ H3PO4 for enhanced surface activation, improved plating adhesion, and electroplating optimization providing exceptional plating results, enhanced coating quality, and superior electroplating manufacturing performance.

Agricultural & Fertilizer Applications

Fertilizer Manufacturing Fertilizer manufacturers utilize Agricultural Grade Phosphoric Acid 85% H3PO4 for phosphate fertilizer production, nutrient enhancement, and agricultural improvement. Agricultural engineers employ H3PO4 for enhanced nutrient availability, improved fertilizer efficiency, and agricultural optimization providing superior fertilizer products, enhanced crop nutrition, and outstanding agricultural manufacturing results.

Soil Amendment Systems Soil treatment companies use specialized Phosphoric Acid for soil conditioning, pH adjustment, and agricultural improvement. Soil amendment specialists employ H3PO4 for enhanced soil chemistry, improved nutrient availability, and agricultural optimization providing exceptional soil treatment results, enhanced crop productivity, and superior agricultural excellence.

Hydroponic Solutions Hydroponic manufacturers utilize Agricultural Grade Phosphoric Acid for nutrient solutions, pH control, and hydroponic enhancement. Hydroponic specialists employ H3PO4 for enhanced nutrient balance, improved plant growth, and hydroponic optimization providing superior hydroponic products, enhanced plant nutrition, and outstanding hydroponic manufacturing results.

Plant Nutrition Systems Plant nutrition companies use Agricultural Grade Phosphoric Acid for foliar fertilizers, nutrient enhancement, and agricultural improvement. Plant nutrition specialists employ H3PO4 for enhanced nutrient uptake, improved plant health, and nutrition optimization providing exceptional plant nutrition results, enhanced agricultural productivity, and superior plant nutrition manufacturing performance.

Water Treatment & Chemical Applications

Water Treatment Systems Water treatment facilities utilize Technical Grade Phosphoric Acid 85% H3PO4 for pH adjustment, scale prevention, and water enhancement. Water treatment engineers employ H3PO4 for enhanced pH control, improved water quality, and treatment optimization providing superior water treatment results, enhanced system efficiency, and outstanding water treatment manufacturing performance.

Boiler Water Treatment Boiler treatment companies use specialized Phosphoric Acid for scale control, corrosion prevention, and water improvement. Boiler water specialists employ H3PO4 for enhanced scale inhibition, improved heat transfer, and boiler optimization providing exceptional boiler treatment results, enhanced system performance, and superior boiler water treatment excellence.

Cooling Water Systems Cooling water manufacturers utilize Technical Grade Phosphoric Acid for cooling towers, scale prevention, and system enhancement. Cooling water specialists employ H3PO4 for enhanced scale control, improved heat exchange, and cooling optimization providing superior cooling water products, enhanced system efficiency, and outstanding cooling water manufacturing results.

Swimming Pool Treatment Pool chemical companies use Technical Grade Phosphoric Acid for pH adjustment, water balance, and pool improvement. Pool treatment specialists employ H3PO4 for enhanced pH control, improved water clarity, and pool optimization providing exceptional pool treatment results, enhanced water quality, and superior pool chemical manufacturing performance.

Chemical Synthesis & Manufacturing Applications

Chemical Processing Chemical manufacturers utilize Technical Grade Phosphoric Acid 85% H3PO4 for chemical synthesis, reaction catalysis, and manufacturing enhancement. Chemical engineers employ H3PO4 for enhanced reaction efficiency, improved product yields, and manufacturing optimization providing superior chemical products, enhanced synthesis quality, and outstanding chemical manufacturing results.

Catalyst Preparation Catalyst companies use specialized Phosphoric Acid for catalyst synthesis, performance enhancement, and manufacturing improvement. Catalyst specialists employ H3PO4 for enhanced catalyst activity, improved reaction selectivity, and manufacturing optimization providing exceptional catalyst results, enhanced chemical performance, and superior catalyst manufacturing excellence.

Polymer Production Polymer manufacturers utilize Technical Grade Phosphoric Acid for polymer synthesis, performance enhancement, and manufacturing improvement. Polymer engineers employ H3PO4 for enhanced polymer properties, improved material performance, and manufacturing optimization providing superior polymer products, enhanced material quality, and outstanding polymer manufacturing results.

Pharmaceutical Intermediates Pharmaceutical intermediate companies use Pharmaceutical Grade Phosphoric Acid for drug synthesis, pharmaceutical enhancement, and manufacturing improvement. Pharmaceutical specialists employ H3PO4 for enhanced synthesis efficiency, improved product purity, and pharmaceutical optimization providing exceptional pharmaceutical results, enhanced drug quality, and superior pharmaceutical manufacturing performance.

Electronics & Semiconductor Applications

Semiconductor Processing Semiconductor manufacturers utilize Electronic Grade Phosphoric Acid 85% H3PO4 for wafer processing, etching operations, and electronics enhancement. Semiconductor engineers employ H3PO4 for enhanced etching precision, improved surface quality, and semiconductor optimization providing superior semiconductor products, enhanced device performance, and outstanding semiconductor manufacturing results.

Circuit Board Manufacturing Electronics companies use specialized Phosphoric Acid for PCB processing, surface preparation, and electronics improvement. Electronics specialists employ H3PO4 for enhanced surface treatment, improved circuit quality, and electronics optimization providing exceptional electronics results, enhanced device reliability, and superior electronics manufacturing excellence.

Display Manufacturing Display manufacturers utilize Electronic Grade Phosphoric Acid for display processing, surface treatment, and electronics enhancement. Display processing engineers employ H3PO4 for enhanced display quality, improved surface properties, and display optimization providing superior display products, enhanced visual performance, and outstanding display manufacturing results.

Solar Cell Production Solar manufacturers use Electronic Grade Phosphoric Acid for solar cell processing, surface texturing, and renewable energy improvement. Solar specialists employ H3PO4 for enhanced cell efficiency, improved energy conversion, and solar optimization providing exceptional solar results, enhanced renewable energy, and superior solar manufacturing performance.

Cleaning & Maintenance Applications

Industrial Cleaning Industrial cleaning companies utilize Technical Grade Phosphoric Acid 85% H3PO4 for equipment cleaning, scale removal, and maintenance enhancement. Industrial cleaning engineers employ H3PO4 for enhanced cleaning efficiency, improved equipment performance, and maintenance optimization providing superior cleaning products, enhanced equipment life, and outstanding industrial cleaning results.

Heat Exchanger Cleaning Heat exchanger services use specialized Phosphoric Acid for scale removal, performance restoration, and maintenance improvement. Heat exchanger specialists employ H3PO4 for enhanced scale dissolution, improved heat transfer, and maintenance optimization providing exceptional maintenance results, enhanced equipment efficiency, and superior heat exchanger cleaning excellence.

Pipeline Cleaning Pipeline maintenance companies utilize Technical Grade Phosphoric Acid for pipeline cleaning, scale removal, and system enhancement. Pipeline specialists employ H3PO4 for enhanced cleaning effectiveness, improved flow characteristics, and pipeline optimization providing superior pipeline products, enhanced system performance, and outstanding pipeline maintenance results.

Equipment Maintenance Maintenance service companies use Technical Grade Phosphoric Acid for equipment cleaning, rust removal, and maintenance improvement. Equipment maintenance specialists employ H3PO4 for enhanced cleaning performance, improved equipment reliability, and maintenance optimization providing exceptional maintenance results, enhanced equipment life, and superior maintenance service performance.

Research & Laboratory Applications

Analytical Chemistry Analytical laboratories utilize Reagent Grade Phosphoric Acid 85% H3PO4 for analytical methods, chemical analysis, and laboratory enhancement. Laboratory technicians employ H3PO4 for enhanced analytical precision, improved testing accuracy, and laboratory optimization providing superior analytical products, enhanced testing reliability, and outstanding laboratory manufacturing results.

Research Studies Research institutions use specialized Phosphoric Acid for scientific research, experimental studies, and research enhancement. Research specialists employ H3PO4 for enhanced experimental capabilities, improved research outcomes, and analytical optimization providing exceptional research results, enhanced scientific discovery, and superior research manufacturing excellence.

Buffer Solutions Laboratory supply companies utilize Reagent Grade Phosphoric Acid for buffer preparation, pH control, and laboratory improvement. Laboratory specialists employ H3PO4 for enhanced buffer capacity, improved pH stability, and laboratory optimization providing superior laboratory products, enhanced analytical performance, and outstanding laboratory manufacturing results.

Quality Control Testing Quality control facilities use Reagent Grade Phosphoric Acid for testing protocols, analytical standards, and quality improvement. Quality control specialists employ H3PO4 for enhanced testing accuracy, improved analytical reliability, and quality optimization providing exceptional quality results, enhanced testing precision, and superior quality control manufacturing performance.

Quality Control & Testing

Comprehensive Quality Assurance Every production batch undergoes extensive testing to ensure compliance with Phosphoric Acid standards, food safety requirements, industrial specifications, and international quality standards. Our quality control laboratory employs advanced analytical techniques including H3PO4 content analysis, density determination, and comprehensive performance evaluation.

Quality assurance procedures include:

- H3PO4 content determination using titration analysis

- Specific gravity measurement using calibrated hydrometers

- Purity assessment using ICP-MS spectroscopy

- Heavy metals analysis using atomic absorption spectroscopy

- Chloride content analysis using ion chromatography

- Sulfate analysis using gravimetric methods

- Iron content determination using colorimetric methods

- Arsenic analysis using hydride generation AAS

- Color determination using APHA color standards

- pH measurement using calibrated electrode systems

- Viscosity testing using rotational viscometer

- Electrical conductivity measurement using conductivity meter

- Microbiological testing for food and pharmaceutical grades

- Thermal stability analysis using thermal methods

- Packaging integrity testing using standard procedures

Storage & Handling Procedures Implement proper storage conditions including corrosion-resistant materials, protection from moisture absorption and temperature extremes, appropriate containment systems, segregation from incompatible materials, and comprehensive safety procedures for maintaining Phosphoric Acid quality and ensuring safe handling throughout storage and application periods.

Environmental & Regulatory Compliance

Food Safety Standards Food Grade Phosphoric Acid complies with FDA, FCC, and international food safety standards ensuring safe use in food applications with established food safety protocols and comprehensive safety assessments for food manufacturing operations.

Industrial Standards Industrial Grade products adhere to ASTM, ANSI, and international industrial requirements ensuring appropriate use in industrial applications with established industrial safety protocols and regulatory compliance for industrial manufacturing operations.

Agricultural Standards Agricultural Grade products meet EPA, agricultural, and international requirements ensuring proper use in agricultural applications with established agricultural safety protocols and performance standards for agricultural manufacturing operations.

Environmental Safety Phosphoric Acid demonstrates moderate environmental impact with controlled discharge requirements, responsible usage guidelines, and environmental management procedures ensuring sustainable operations with comprehensive environmental safety measures and chemical management protocols.

Performance Advantages & Benefits

✔ Premium Acidification Component – Superior pH control properties and chemical reactivity

✔ Outstanding Industrial Quality – Excellent metal treatment and surface preparation applications

✔ Agricultural Excellence – Exceptional fertilizer and nutrient enhancement properties

✔ Multiple Applications – Suitable for food, industrial, agricultural, and water treatment processing

✔ Processing Excellence – Superior solubility properties and manufacturing compatibility

✔ Quality Consistency – Uniform acidification activity across production batches

✔ Safety Profile – Proven safety and handling characteristics with proper protocols

✔ Environmental Management – Controlled environmental impact with proper waste management

✔ Regulatory Compliance – Approved for food, industrial, agricultural, and water treatment applications

✔ Cost Effectiveness – Economic acidification solution with superior performance characteristics

✔ Chemical Reactivity – Exceptional reaction efficiency and process optimization

✔ Global Availability – Reliable supply chains and worldwide distribution networks

✔ Technical Versatility – Multiple grade options and application compatibility

✔ Technical Support – Complete application guidance and optimization services

Our Phosphoric Acid 85% products represent industry-leading standards in mineral acid and chemical processing technology, specifically manufactured for demanding industrial applications, food processing operations, agricultural production, and specialized chemical processing requiring exceptional acidification properties, reliable performance, and comprehensive regulatory compliance. We provide complete technical support, application guidance, and performance consultation to ensure optimal results across your specialized industrial, food processing, agricultural, or chemical applications.

For detailed specifications, technical data sheets, or application-specific recommendations, contact our specialized Phosphoric Acid division. We offer complete support including product selection, application optimization, performance testing, regulatory guidance, quality assurance, and technical assistance to maximize effectiveness in your industrial, food processing, agricultural, or chemical applications.

For more information about our products, feel free to Contact Us today.

Reviews

There are no reviews yet.