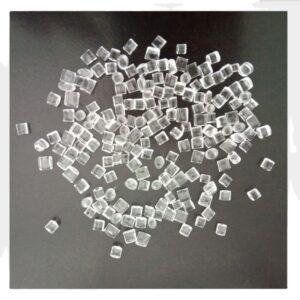

PCTG Granules

PCTG Granules

Premium Quality PCTG Granules – BPA-Free Copolyester for Medical Device Manufacturing, Cosmetic Packaging, Consumer Products & High-Temperature Applications

PCTG Granules are high-performance transparent copolyester thermoplastics extensively utilized in medical device manufacturing, cosmetic packaging applications, consumer products, household items, and industrial applications requiring superior clarity, chemical resistance, and exceptional toughness.

✅ Ultra-High Performance PCTG Granules – Superior Clarity & Multi-Industry Performance

✅ Multiple Grade Options – Injection Molding, Extrusion, Blow Molding, Medical Grade for Specialized Applications

✅ Excellent Chemical Resistance – BPA-Free, FDA Approved for Optimal Safety Standards

✅ Multi-Industry Compatible – Enhanced Medical, Cosmetic, Household & Industrial Properties

✅ Medical Device, Cosmetic Packaging, Consumer Goods & High-Temperature Applications

High-Quality PCTG Granules for Medical Devices, Cosmetic Packaging & Consumer Applications

PCTG Granules represent advanced copolyester technology specifically formulated for medical device manufacturing, cosmetic packaging applications, consumer products, household items, and industrial operations requiring exceptional clarity, chemical resistance, and multi-industry effectiveness. This essential thermoplastic copolyester serves critical functions across medical procedures, cosmetic applications, consumer goods manufacturing, and specialized systems requiring controlled transparency, impact resistance, and processing capabilities with exceptional reliability.

At Chemicals & Process Equipment Limited, we supply medical-grade PCTG Granules manufactured under stringent quality control standards and international specifications. Our comprehensive product range includes medical grade PCTG, injection molding grades, blow molding formulations, and custom compounds meeting diverse requirements for medical manufacturing, cosmetic applications, consumer goods, and specialized applications across global medical, cosmetic, consumer, and industrial markets.

✅ Advanced Copolyester Technology – Optimized Processing Properties & Multi-Industry Performance ✅ Consistent Quality Standards – Multiple Grade Classifications with Comprehensive Documentation ✅ Essential Thermoplastic Copolyester – Superior Medical, Cosmetic & Consumer Goods Performance ✅ Multi-Industry Applications – Medical, Cosmetic, Consumer Goods & Industrial Systems ✅ Technical Support Package – Complete Application Guidance & Performance Optimization

The Global PCTG Market is expected to grow from USD 216.55 million in 2025 to USD 291.16 million by 2033, at a CAGR of 3.77% during the forecast period, while the copolyester PCTG material market is expected to reach USD 235 million by 2030. This growth is driven by increasing medical device demand, expanding cosmetic packaging applications, growing consumer goods production, and rising household product requirements across global medical and consumer markets.

Technical Specifications & PCTG Granules Properties

| Property | Medical Grade | Injection Grade | Blow Molding Grade | Extrusion Grade |

|---|---|---|---|---|

| Density (g/cm³) | 1.27-1.29 | 1.27-1.30 | 1.26-1.29 | 1.27-1.29 |

| Melt Index (g/10min) | 2.0-8.0 | 3.0-15.0 | 1.5-6.0 | 2.0-10.0 |

| Tensile Strength (MPa) | 50-65 | 45-60 | 48-62 | 50-63 |

| Elongation at Break (%) | 120-200 | 100-180 | 130-220 | 110-190 |

| Flexural Strength (MPa) | 80-95 | 75-90 | 78-92 | 80-94 |

| Flexural Modulus (GPa) | 2.1-2.4 | 2.0-2.3 | 2.0-2.3 | 2.1-2.4 |

| Impact Strength (kJ/m²) | No break | No break | No break | No break |

| Heat Deflection Temperature (°C) | 70-85 | 68-82 | 70-84 | 72-86 |

| Melting Point (°C) | 280-290 | 280-290 | 280-290 | 280-290 |

| Glass Transition Temperature (°C) | 85-95 | 85-95 | 85-95 | 85-95 |

| Service Temperature (°C) | -40 to +70 | -40 to +70 | -40 to +70 | -40 to +70 |

| Thermal Conductivity (W/m·K) | 0.19-0.22 | 0.19-0.22 | 0.19-0.22 | 0.19-0.22 |

| Coefficient of Expansion (×10⁻⁵/°C) | 6.5-7.5 | 6.5-7.5 | 6.5-7.5 | 6.5-7.5 |

| Dielectric Strength (kV/mm) | 15-25 | 15-25 | 15-25 | 15-25 |

| Volume Resistivity (Ω·cm) | >10¹⁴ | >10¹⁴ | >10¹⁴ | >10¹⁴ |

| Water Absorption (%) | 0.1-0.2 | 0.1-0.2 | 0.1-0.2 | 0.1-0.2 |

| Chemical Resistance | Excellent | Excellent | Excellent | Excellent |

| UV Resistance | Good | Good | Good | Good |

| Transparency | Crystal Clear | Crystal Clear | Crystal Clear | Crystal Clear |

| Processing Method | Injection, extrusion, blow molding | |||

| Haze (%) | <1 | <1 | <1 | <1 |

| Light Transmission (%) | >90 | >90 | >90 | >90 |

| Processing Temperature (°C) | 250-290 | 250-290 | 250-290 | 250-290 |

| Mold Temperature (°C) | 70-90 | 70-90 | 70-90 | 70-90 |

| Injection Pressure (MPa) | 80-120 | 80-120 | N/A | N/A |

| Screw Speed (rpm) | 50-150 | 50-200 | 40-120 | 45-140 |

| Drying Required | Yes (4-6 hours at 65°C) | Yes | Yes | Yes |

| Storage Conditions | Cool, dry environment | |||

| Shelf Life | 60 months | |||

| Packaging Options | 25kg bags, octabins, bulk |

Available Grade Types:

- Medical Grade for healthcare and pharmaceutical applications

- Injection Molding Grade for molded components and parts

- Blow Molding Grade for bottles and containers

- Extrusion Grade for sheets and profiles

- Food Contact Grade for food packaging applications

- Cosmetic Grade for beauty and personal care packaging

- Electronics Grade for electrical components

- Automotive Grade for automotive applications

Specialized Processing Solutions:

- Injection molding for precision components

- Blow molding for bottles and containers

- Extrusion for sheets and films

- Thermoforming for packaging applications

- 3D printing filament applications

- Medical device manufacturing

- Cosmetic container production

- Electronic component housing

Medical & Healthcare Applications

Medical Device Components

Medical device manufacturers utilize PCTG Granules for disposable medical devices, surgical instruments, and healthcare equipment requiring medical-grade specifications. Healthcare companies employ PCTG granules for diagnostic equipment, medical housings, and medical component applications.

Pharmaceutical Packaging

Pharmaceutical manufacturers use PCTG Granules for drug containers, pharmaceutical bottles, and medication packaging requiring pharmaceutical specifications. Drug companies employ PCTG granules for medicine bottles, pharmaceutical vials, and drug packaging applications.

Laboratory Equipment & Supplies

Laboratory manufacturers utilize PCTG Granules for lab containers, scientific equipment, and laboratory supplies requiring laboratory specifications. Research facilities employ PCTG granules for sample containers, laboratory glassware alternatives, and scientific equipment applications.

Medical Facility Products

Healthcare facility manufacturers use PCTG Granules for hospital supplies, medical facility equipment, and healthcare applications requiring medical facility specifications. Hospital suppliers employ PCTG granules for medical storage, facility equipment, and healthcare component applications.

Cosmetic & Personal Care Applications

Cosmetic Packaging Containers

Cosmetic manufacturers utilize PCTG Granules for beauty product containers, cosmetic bottles, and personal care packaging requiring cosmetic specifications. Beauty companies employ PCTG granules for shampoo bottles, lotion containers, and cosmetic packaging applications.

Personal Care Product Housing

Personal care manufacturers use PCTG Granules for skincare containers, haircare bottles, and beauty product packaging requiring personal care specifications. Beauty brands employ PCTG granules for premium cosmetic containers, luxury packaging, and personal care applications.

Fragrance & Perfume Bottles

Fragrance manufacturers utilize PCTG Granules for perfume bottles, cologne containers, and fragrance packaging requiring fragrance specifications. Perfume companies employ PCTG granules for premium bottles, fragrance containers, and luxury fragrance applications.

Beauty Tool & Applicator Components

Beauty tool manufacturers use PCTG Granules for cosmetic applicators, beauty devices, and personal care tools requiring beauty specifications. Cosmetic companies employ PCTG granules for makeup applicators, beauty tools, and cosmetic device applications.

Consumer Goods & Household Applications

Household Products & Storage

Consumer goods manufacturers utilize PCTG Granules for household containers, storage products, and home organization requiring household specifications. Home goods companies employ PCTG granules for food storage, kitchen containers, and household storage applications.

Kitchen & Dining Products

Kitchen manufacturers use PCTG Granules for food containers, dinnerware, and kitchen products requiring food contact specifications. Dinnerware companies employ PCTG granules for plates, cups, and kitchen utensil applications.

Small Home Appliance Components

Appliance manufacturers utilize PCTG Granules for small appliance housings, appliance components, and home equipment requiring appliance specifications. Home appliance companies employ PCTG granules for blender jars, coffee makers, and appliance housing applications.

Sports & Recreation Equipment

Sports equipment manufacturers use PCTG Granules for water bottles, sports containers, and recreational products requiring sports specifications. Recreation companies employ PCTG granules for sports bottles, outdoor equipment, and recreational applications.

Industrial & Electronics Applications

Electronic Component Housing

Electronics manufacturers utilize PCTG Granules for electronic housings, component covers, and electrical applications requiring electronic specifications. Technology companies employ PCTG granules for device housings, electronic components, and electrical housing applications.

Automotive Interior Components

Automotive manufacturers use PCTG Granules for interior parts, automotive components, and vehicle applications requiring automotive specifications. Auto companies employ PCTG granules for dashboard components, interior trim, and automotive part applications.

Industrial Equipment Components

Industrial manufacturers utilize PCTG Granules for equipment housings, industrial components, and manufacturing applications requiring industrial specifications. Manufacturing companies employ PCTG granules for machine covers, industrial parts, and equipment applications.

Specialty Chemical Containers

Chemical manufacturers use PCTG Granules for chemical containers, specialty storage, and chemical applications requiring chemical resistance specifications. Chemical companies employ PCTG granules for laboratory containers, chemical storage, and specialty applications.

Quality Control & Testing Procedures

Comprehensive Quality Assurance

Every production batch undergoes extensive testing to ensure compliance with medical device standards, food contact regulations, and international quality requirements. Our quality control laboratory employs advanced analytical techniques including thermal analysis, mechanical testing, and chemical resistance evaluation. PCTG offers excellent clarity and better impact resistance and elongation than Polycarbonate (PC), making it suitable for relatively high load bearing applications.

For comprehensive information on plastic material testing standards and procedures, refer to the ASTM International Standards for Plastics, which provides detailed guidelines for evaluating plastic material properties and performance characteristics.

Quality assurance procedures include:

- Thermal analysis using DSC and TGA methods

- Mechanical property testing using universal testing machine

- Impact resistance testing using Charpy and Izod methods

- Chemical resistance testing using solvent immersion

- Transparency measurement using haze meter

- Color evaluation using spectrophotometer

- Melt flow index testing using melt indexer

- Density measurement using density gradient column

- Medical device biocompatibility testing (ISO 10993)

- Food contact migration testing using simulants

- UV resistance testing using weatherometer

- Processing performance evaluation using pilot equipment

Application Guidelines & Best Practices

Injection Molding Guidelines

Establish proper molding procedures for PCTG Granules including temperature control, mold design, and processing parameters for optimal part quality and production efficiency.

Blow Molding Methods

Develop appropriate blow molding procedures including temperature profiles, pressure control, and cooling methods for maximum processing performance and container quality.

Storage & Handling Procedures

Implement proper storage conditions including moisture protection, temperature control, and contamination prevention for maintaining PCTG granules quality and processing performance throughout storage periods.

Market Applications & Industry Trends

Medical Device Industry Growth

Expanding healthcare demand and growing medical technology markets drive continued growth in medical-grade PCTG applications for devices, equipment, and medical components across global healthcare operations.

Cosmetic Packaging Market Expansion

Growing beauty industry and expanding premium cosmetic markets support increased adoption of cosmetic-grade PCTG for containers, bottles, and packaging applications worldwide.

Consumer Electronics Development

Expanding electronics manufacturing and growing device complexity drive growth in electronic-grade PCTG applications for housings, components, and electronic device applications.

Environmental & Regulatory Compliance

Medical Device Standards & Certifications

PCTG Granules comply with FDA medical device regulations, ISO 10993 biocompatibility standards, and international medical device guidelines ensuring safe use in medical applications.

Food Contact Standards & Safety

Adherence to FDA food contact regulations, EU food safety standards, and international food packaging guidelines supports responsible use in food contact and consumer applications.

Cosmetic & Personal Care Standards

Compliance with cosmetic regulations, personal care safety standards, and international guidelines ensures appropriate use in cosmetic and beauty applications.

Performance Advantages & Technical Benefits

✔ Crystal Clear Transparency – Superior optical clarity for demanding visual applications ✔ Exceptional Impact Resistance – Outstanding toughness and durability for critical applications ✔ Excellent Chemical Resistance – Resistance to acids, alcohols, and cleaning chemicals ✔ BPA-Free Formulation – Safe, non-toxic material for food contact and medical applications ✔ Superior Processing Properties – Excellent melt flow and processing characteristics ✔ High Heat Resistance – Maintains properties at elevated temperatures ✔ UV Stability – Good resistance to ultraviolet radiation and weathering ✔ Dimensional Stability – Low shrinkage and excellent dimensional control ✔ Biocompatibility – Medical grade options for healthcare applications ✔ Recyclability – Thermoplastic recyclability for sustainable applications ✔ Sterilization Compatibility – Gamma radiation and EtO sterilization resistance ✔ Low Extractables – Minimal leaching for sensitive applications

Our PCTG Granules products represent industry-leading standards in copolyester technology and multi-industry solutions, specifically formulated for demanding medical operations, cosmetic applications, consumer goods production, and specialized industrial applications. We provide comprehensive technical support, processing guidance, and application consultation to ensure optimal performance across your specialized medical, cosmetic, consumer goods, or industrial applications.

For detailed specifications, technical data sheets, or application-specific recommendations, contact our specialized plastics division. We offer complete support including processing optimization, equipment recommendations, and technical guidance to maximize effectiveness in your medical, cosmetic, consumer goods, or industrial applications.

For more information about our products, feel free to Contact Us today.

Reviews

There are no reviews yet.