OCTYL HYDROXAMIC ACID

Octyl Hydroxamic Acid (OHA)

Premium Grade Octyl Hydroxamic Acid 99%+ Purity – Specialized Mining Collector

Octyl hydroxamic acid is a highly effective flotation collector extensively utilized in mineral processing, rare earth element extraction, selective mineral separation, and advanced metallurgical applications. Our premium-grade octyl hydroxamic acid delivers exceptional chelating properties for copper mineral flotation, rare earth recovery, and specialized mining operations with consistent performance standards.

✅ 99%+ Technical & Mining Grade Purity – Superior Collector Performance

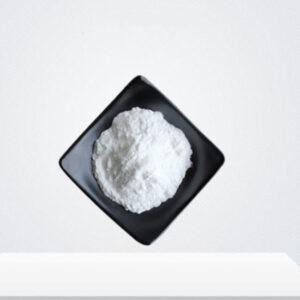

✅ White to Off-White Crystalline Powder – High Surface Activity

✅ Technical, Mining & Research Grades Available

✅ CAS 7377-03-9 Certified with Enhanced Stability

✅ Used in Mineral Flotation, Rare Earth Extraction, Copper Recovery, and Selective Separation

High-Performance Octyl Hydroxamic Acid for Mining & Metallurgical Applications

Octyl hydroxamic acid (C₈H₁₇NO₂) presents as white to off-white crystalline powder with exceptional chelating and surface-active properties, serving critical functions across mineral flotation processes, rare earth element recovery, copper mineral separation, and advanced metallurgical operations. This versatile hydroxamic acid collector provides unique metal ion complexation capabilities essential for selective mineral separation, particularly effective in bastnaesite flotation and monazite recovery operations.

At Chemicals & Process Equipment Limited, we supply technical-grade and mining-grade Octyl Hydroxamic Acid (99% minimum purity) manufactured under strict quality control protocols and mining industry specifications. Our product portfolio meets demanding requirements for flotation operations, rare earth processing, and specialized metallurgical applications across global mining sectors.

✅ Technical Grade Standards – CAS 7377-03-9 Specification Compliance

✅ Mining Quality Control – Flotation & Separation Applications

✅ Research Grade Certification – Laboratory & Development Quality

✅ Multi-Application Platform – Versatile Collector Performance

✅ Complete Documentation – Comprehensive Quality Assurance Package

Technical Specifications & Chemical Properties

| Property | Specification |

|---|---|

| Chemical Formula | C₈H₁₇NO₂ |

| CAS Number | 7377-03-9 |

| EINECS Number | 230-833-8 |

| Molecular Weight | 159.23 g/mol |

| Appearance | White to off-white crystalline powder |

| Purity | ≥ 99.0% (Technical/Mining Grade) |

| Melting Point | 52-54°C |

| pH (1% Solution) | 10-13 (optimal flotation range) |

| Water Solubility | Moderately soluble |

| Density | 0.95-1.05 g/cm³ |

| Loss on Drying | ≤ 0.5% |

| Heavy Metals | ≤ 20 ppm (as Pb) |

| Packaging Options | 25kg bags, 200kg drums, 1000kg IBC containers |

Specialized Packaging Solutions:

- 25kg PE bags with moisture-resistant barrier protection

- 1000kg Intermediate Bulk Container (IBC) drums for industrial operations

- Nitrogen-purged packaging for research-grade applications

- Climate-controlled storage containers for mining site delivery

Mineral Flotation & Processing Applications

Rare Earth Element Recovery Octyl hydroxamic acid demonstrates exceptional selectivity in bastnaesite/fluorite separation, capable of creating pentacoordinate rings with Ce³⁺ ions on bastnaesite surfaces. In monazite flotation operations, OHA achieves flotation recovery rates up to 72.65% when enhanced with Fe³⁺ additions, making it essential for rare earth element extraction and processing.

Copper Mineral Flotation Hydroxamate surfactants serve as effective collectors for copper mineral flotation, with octyl hydroxamic acid showing particular efficacy in galena flotation through controlled adsorption mechanisms. It enables selective copper recovery while maintaining high concentrate grades and metallurgical performance.

Tungsten & Complex Ore Processing Fine wolframite flotation utilizes octyl hydroxamic acid as a selective collector, effectively separating tungsten minerals from quartz and other gangue materials. The collector demonstrates superior performance in complex ore systems requiring precise mineral separation.

Manganese & Oxide Mineral Recovery Rhodochrosite fines flotation benefits from octyl hydroxamic acid’s ability to induce hydrophobic agglomeration, improving recovery of fine manganese minerals through enhanced flotation mechanics. It provides effective separation of oxide minerals from silicate gangue materials.

For comprehensive information on octyl hydroxamic acid applications in mineral flotation, refer to this detailed flotation mechanism study by ScienceDirect. Our mining chemicals expertise provides specialized guidance for optimal flotation performance.

Advanced Metallurgical Applications

Selective Metal Ion Complexation Chelating agents demonstrate metal specificity that enables their function as effective mineral processing reagents. Octyl hydroxamic acid forms stable complexes with specific metal ions, enabling precise separation of target minerals from complex ore matrices.

Perovskite & Titanium Mineral Processing Flotation behaviors of perovskite, titanaugite, and magnesium aluminate spinel demonstrate enhanced recovery when utilizing octyl hydroxamic acid as the primary collector, particularly effective in titanium-bearing mineral concentration processes.

pH-Dependent Flotation Systems Operating pH ranges from 10 to 13 provide extremely strong and effective flotation and collection ability, enabling optimal collector performance across alkaline flotation conditions common in mineral processing operations.

Multi-Metal Recovery Systems Octyl hydroxamic acid enables simultaneous recovery of multiple metal values from complex ores, providing economic advantages through improved metallurgical recoveries and reduced processing costs in polymetallic ore treatment.

Research & Development Applications

Polymer Modification & Material Science Hydroxamic acid modifications of polyacrylic resins increase adsorption performance for rare earth ions, enabling preparation of adsorbents with high efficiency and superior stability for REE recovery. This demonstrates expanding applications in advanced materials and environmental remediation.

Surface Chemistry Research Octyl hydroxamic acid serves as a model compound for studying metal-collector interactions, surface adsorption mechanisms, and flotation thermodynamics in academic and industrial research environments.

Analytical Chemistry Applications In analytical applications, octyl hydroxamic acid functions as a chelating agent, metal extraction reagent, and separation medium for trace metal analysis and environmental monitoring applications.

Environmental Remediation Hydroxamic acid chemistry enables selective metal extraction from contaminated waters, mine drainage treatment, and industrial effluent processing for environmental protection and resource recovery.

Quality Control & Analytical Testing

Comprehensive Quality Assurance Every production batch undergoes extensive testing to ensure compliance with technical-grade, mining, and research specifications. Our quality control laboratory employs advanced analytical techniques including HPLC analysis, NMR spectroscopy, and elemental analysis to verify purity and identify trace impurities.

Quality testing procedures include:

- Purity determination via high-performance liquid chromatography

- Melting point analysis using differential scanning calorimetry

- Heavy metals testing by inductively coupled plasma spectroscopy

- Moisture content analysis through Karl Fischer titration

- pH measurement using calibrated electrode systems

- Particle size distribution via laser diffraction analysis

Storage & Handling Specifications

Optimal Storage Requirements

- Store in environment away from exposure to water and excessive heat of fire or sunlight

- Maintain storage temperature between 15-25°C in controlled humidity conditions

- Protect from moisture exposure using sealed container storage with desiccant

- Store in cool, dry, well-ventilated areas away from incompatible materials

- Implement climate-controlled storage for long-term stability preservation

Professional Handling Guidelines

- Use appropriate personal protective equipment including chemical-resistant gloves and safety glasses

- Provide adequate ventilation during material handling and flotation operations

- Avoid dust generation through controlled transfer and dispensing procedures

- Maintain emergency eyewash and safety shower facilities in processing areas

- Follow mining industry safety protocols for flotation reagent handling

Industrial Applications & Processing

Flotation Circuit Integration Octyl hydroxamic acid integrates seamlessly into existing flotation circuits, compatible with conventional flotation equipment, pH control systems, and standard processing conditions common in mineral processing operations.

Dosage Optimization Typical dosage ranges from 50-200 g/t depending on ore type, mineral composition, and flotation conditions. Optimal dosages are determined through flotation testing and metallurgical evaluation for specific ore characteristics.

Synergistic Collector Systems Octyl hydroxamic acid demonstrates synergistic effects when combined with other collectors, enabling enhanced selectivity and improved metallurgical performance in complex ore processing applications.

Process Water Compatibility Compatible with various process water qualities including recycled water, high-salinity brines, and mine water systems commonly encountered in mining operations.

Environmental & Safety Considerations

Environmental Impact Assessment Octyl hydroxamic acid provides environmentally favorable alternatives to traditional collectors in many applications. It demonstrates controlled environmental persistence and enables reduced reagent consumption through enhanced selectivity.

Workplace Safety Protocols Established occupational exposure guidelines ensure safe workplace handling during flotation operations and mineral processing activities. Proper ventilation, personal protective equipment, and emergency response procedures maintain worker safety and health protection.

Regulatory Compliance Our octyl hydroxamic acid meets international safety standards and regulatory requirements for mining chemical applications. Complete documentation includes Safety Data Sheets with GHS classification and transportation guidelines per mining industry regulations.

Technical Support & Application Development

Flotation Testing Services Our technical team provides comprehensive flotation testing, process optimization, and metallurgical evaluation services to determine optimal octyl hydroxamic acid applications for specific ore types and processing conditions.

Custom Formulation Development We develop customized collector formulations incorporating octyl hydroxamic acid for specialized flotation applications requiring enhanced selectivity, improved recovery, or specific processing conditions.

Process Engineering Support Technical support includes flotation circuit design recommendations, dosage optimization protocols, and process control strategies for successful octyl hydroxamic acid implementation in mining operations.

Training & Technical Transfer Comprehensive training programs ensure successful technology transfer and optimal performance in octyl hydroxamic acid applications across diverse mining and metallurgical operations.

Why Choose Chemicals & Process Equipment Limited?

✔ Multi-Grade Excellence – Technical, mining, and research specifications available ✔ Quality Leadership – Advanced testing ensures consistent high-purity standards ✔ Application Expertise – Technical support across diverse mining applications ✔ Regulatory Assurance – Complete documentation for mining and industrial use ✔ Global Distribution – Reliable supply chain supporting international mining operations

Our octyl hydroxamic acid products represent the highest standards in flotation collector chemistry, specifically formulated for demanding mineral processing, rare earth recovery, and metallurgical applications. We provide comprehensive technical support, metallurgical testing, and quality assurance to ensure optimal performance across your specialized mining and processing operations.

For detailed specifications, flotation testing protocols, or technical documentation, contact our specialized mining chemicals team. We provide comprehensive support including flotation optimization, metallurgical evaluation, and process development assistance to maximize effectiveness in your mineral processing, rare earth recovery, or metallurgical applications.

Reviews

There are no reviews yet.