Liquid Silicone Rubber

Liquid Silicone Rubber

Premium Quality Food Grade Liquid Silicone Rubber – FDA Approved Medical Grade LSR for Baby Bottle Nipples, Pacifiers, Teethers & Infant Care Products

Food Grade Liquid Silicone Rubber for baby bottle nipple applications are high-performance medical grade elastomers extensively utilized in infant care product manufacturing, baby bottle nipple production, pacifier applications, and pediatric medical devices requiring superior biocompatibility, food safety, and exceptional softness.

✅ Ultra-High Performance Food Grade LSR – Superior Safety & Medical Grade Performance

✅ Baby Product Specialized Grade – Injection Molding, Compression Molding, FDA Approved for Infant Applications

✅ Excellent Biocompatibility – BPA-Free, Non-Toxic, Hypoallergenic for Optimal Child Safety

✅ Multi-Application Compatible – Enhanced Baby Bottles, Pacifiers, Teethers & Infant Care Properties

✅ Baby Bottle Nipples, Pacifiers, Teething Products & Medical Device Applications

High-Quality Food Grade Liquid Silicone Rubber for Baby Bottle Nipple Manufacturing & Infant Care Products

Food Grade Liquid Silicone Rubber for baby bottle nipple represents advanced medical grade elastomer technology specifically formulated for infant care product manufacturing, baby bottle nipple production, pacifier applications, and pediatric medical devices requiring exceptional biocompatibility, food safety, and multi-application effectiveness. This essential liquid silicone rubber serves critical functions across baby feeding products, infant care items, child safety applications, and specialized pediatric medical devices requiring controlled softness, tear resistance, and processing capabilities with exceptional safety reliability.

At Chemicals & Process Equipment Limited, we supply medical-grade Food Grade Liquid Silicone Rubber manufactured under stringent quality control standards and international medical device specifications. Our comprehensive product range includes baby bottle nipple grade, pacifier grade, teether applications, and custom medical formulations meeting diverse requirements for infant product manufacturing, pediatric applications, child care products, and specialized medical devices across global baby care, medical device, pediatric, and consumer safety markets.

✅ Advanced Medical Grade Elastomer Technology – Optimized Processing Properties & Multi-Application Safety Performance

✅ Consistent Quality Standards – Multiple Grade Classifications with Comprehensive Medical Documentation

✅ Essential Liquid Silicone Rubber – Superior Baby Care, Medical Device & Pediatric Safety Performance

✅ Multi-Industry Applications – Baby Products, Medical Devices, Pediatric Care & Safety Systems

✅ Technical Support Package – Complete Application Guidance & Safety Performance Optimization

The global liquid silicone rubber market size was valued at USD 2.81 billion in 2023 and is projected to reach USD 4.97 billion by 2030, growing at a CAGR of 8.5% from 2024 to 2030, while another report indicates the market valued at USD 2.8 billion in 2024 to reach USD 5.4 billion by 2033 at a CAGR of 7.13% during 2025-2033. This growth is driven by increasing baby care product demand, expanding medical device applications, growing pediatric healthcare requirements, and rising infant safety standards across global baby care and medical markets.

Technical Specifications & Food Grade LSR for Baby Bottle Nipple Properties

| Property | Baby Nipple Grade | Pacifier Grade | Teether Grade | Medical Device Grade |

|---|---|---|---|---|

| Durometer (Shore A) | 10-25 | 15-30 | 20-35 | 10-40 |

| Tensile Strength (MPa) | 6-10 | 7-11 | 8-12 | 6-12 |

| Elongation at Break (%) | 400-600 | 350-550 | 300-500 | 350-600 |

| Tear Strength (kN/m) | 15-25 | 18-28 | 20-30 | 15-30 |

| Compression Set (%) | <10 | <12 | <15 | <10 |

| Specific Gravity | 1.10-1.20 | 1.12-1.22 | 1.15-1.25 | 1.10-1.25 |

| Service Temperature (°C) | -40 to +200 | -40 to +200 | -40 to +200 | -40 to +200 |

| Glass Transition Temperature (°C) | -120 | -120 | -120 | -120 |

| Thermal Conductivity (W/m·K) | 0.20-0.25 | 0.20-0.25 | 0.20-0.25 | 0.20-0.25 |

| Coefficient of Expansion (×10⁻⁵/°C) | 24-30 | 24-30 | 24-30 | 24-30 |

| Dielectric Strength (kV/mm) | 18-25 | 18-25 | 18-25 | 18-25 |

| Volume Resistivity (Ω·cm) | >10¹⁴ | >10¹⁴ | >10¹⁴ | >10¹⁴ |

| Water Absorption (%) | <0.1 | <0.1 | <0.1 | <0.1 |

| Rebound Resilience (%) | 45-65 | 50-70 | 55-75 | 45-75 |

| Biocompatibility | USP Class VI | USP Class VI | USP Class VI | USP Class VI |

| Cytotoxicity | Non-cytotoxic | Non-cytotoxic | Non-cytotoxic | Non-cytotoxic |

| Processing Method | Injection, compression, liquid injection molding | |||

| Cure Time (seconds) | 15-60 | 15-60 | 15-60 | 15-60 |

| Cure Temperature (°C) | 150-200 | 150-200 | 150-200 | 150-200 |

| Pot Life (hours) | 4-8 | 4-8 | 4-8 | 4-8 |

| Mix Ratio | 1:1 to 10:1 | 1:1 to 10:1 | 1:1 to 10:1 | 1:1 to 10:1 |

| Viscosity (cP) | 1000-10000 | 1000-10000 | 1000-10000 | 1000-10000 |

| Thixotropic Index | 1.2-2.0 | 1.2-2.0 | 1.2-2.0 | 1.2-2.0 |

| Food Contact Approval | FDA 21CFR177.2600 | FDA 21CFR177.2600 | FDA 21CFR177.2600 | FDA 21CFR177.2600 |

| Medical Device Standards | ISO 10993 | ISO 10993 | ISO 10993 | ISO 10993 |

| BPA Content | BPA-Free | BPA-Free | BPA-Free | BPA-Free |

| Phthalate Content | Phthalate-Free | Phthalate-Free | Phthalate-Free | Phthalate-Free |

| Heavy Metal Content | <10 ppm | <10 ppm | <10 ppm | <10 ppm |

| Volatile Organic Compounds | <0.5% | <0.5% | <0.5% | <0.5% |

| Sterilization Methods | Steam, EtO, Gamma, E-beam | |||

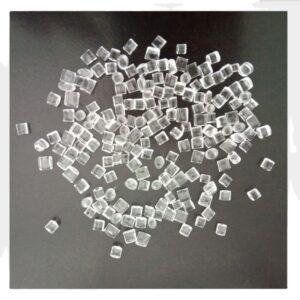

| Color Options | Clear, custom colors available | |||

| Packaging | 20kg drums, custom packaging | |||

| Shelf Life | 12-24 months | |||

| Storage Temperature | 15-25°C |

Available Grade Types:

- Baby Bottle Nipple Grade for infant feeding applications

- Pacifier Grade for soothers and comfort products

- Teether Grade for infant teething products

- Medical Device Grade for pediatric medical applications

- Food Contact Grade for baby feeding accessories

- Hypoallergenic Grade for sensitive skin applications

- Antimicrobial Grade for enhanced hygiene

- Transparent Grade for visual applications

- Colored Grade for aesthetic applications

- Custom Grades for specialized requirements

Specialized Processing Solutions:

- Liquid injection molding for precision nipples

- Compression molding for pacifiers and teethers

- Transfer molding for complex geometries

- Overmolding for multi-material products

- Insert molding for reinforced products

- Multi-shot molding for color combinations

- Hot runner systems for automated production

- Clean room processing for medical applications

Baby Feeding & Nutrition Applications

Baby Bottle Nipples & Components Baby product manufacturers utilize Food Grade LSR for bottle nipples, anti-colic valves, and feeding accessories requiring baby feeding specifications. Infant nutrition companies employ LSR for natural-feel nipples, variable flow systems, and feeding component applications.

Infant Formula & Feeding Systems Formula manufacturers use Food Grade LSR for feeding system components, mixing accessories, and nutrition delivery requiring infant formula specifications. Baby nutrition companies employ LSR for formula dispensers, feeding tubes, and nutrition system applications.

Breast Pump Components & Accessories Breast pump manufacturers utilize Food Grade LSR for pump flanges, tubing, and collection components requiring breast pump specifications. Lactation companies employ LSR for comfort accessories, valve systems, and pumping component applications.

Weaning & Transitional Products Baby food manufacturers use Food Grade LSR for weaning spoons, training cups, and transitional feeding requiring weaning specifications. Infant nutrition companies employ LSR for self-feeding products, weaning accessories, and transition feeding applications.

Infant Care & Comfort Applications

Pacifiers & Soothers Pacifier manufacturers utilize Food Grade LSR for soother nipples, shields, and comfort products requiring pacifier specifications. Baby comfort companies employ LSR for orthodontic pacifiers, night pacifiers, and soothing product applications.

Teething Products & Accessories Teething product manufacturers use Food Grade LSR for teething rings, textured toys, and comfort accessories requiring teething specifications. Baby care companies employ LSR for teething necklaces, textured soothers, and teething relief applications.

Baby Sleep & Comfort Products Sleep product manufacturers utilize Food Grade LSR for sleep accessories, comfort items, and bedtime products requiring baby sleep specifications. Infant comfort companies employ LSR for sleep aids, comfort objects, and bedtime accessory applications.

Sensory & Development Toys Toy manufacturers use Food Grade LSR for sensory toys, developmental products, and infant stimulation requiring toy safety specifications. Baby development companies employ LSR for textured toys, sensory balls, and developmental toy applications.

Medical & Healthcare Applications

Pediatric Medical Devices Medical device manufacturers utilize Food Grade LSR for pediatric components, medical accessories, and healthcare devices requiring pediatric medical specifications. Healthcare companies employ LSR for infant monitors, medical tubing, and pediatric device applications.

Neonatal Care Products NICU equipment manufacturers use Food Grade LSR for neonatal interfaces, monitoring components, and intensive care requiring neonatal specifications. Hospital suppliers employ LSR for premature infant products, NICU accessories, and neonatal care applications.

Pediatric Surgical Devices Surgical device manufacturers utilize Food Grade LSR for pediatric instruments, surgical accessories, and operative tools requiring pediatric surgery specifications. Medical companies employ LSR for minimally invasive tools, surgical guides, and pediatric surgical applications.

Rehabilitation & Therapy Products Therapy product manufacturers use Food Grade LSR for pediatric rehabilitation, therapy tools, and developmental aids requiring therapy specifications. Healthcare providers employ LSR for sensory therapy, motor development, and rehabilitation applications.

Consumer & Safety Applications

Baby Proofing & Safety Products Safety product manufacturers utilize Food Grade LSR for cabinet locks, edge guards, and child safety requiring safety specifications. Consumer safety companies employ LSR for electrical outlet covers, drawer locks, and baby proofing applications.

Bath & Hygiene Products Bath product manufacturers use Food Grade LSR for bath toys, hygiene accessories, and water play requiring bath safety specifications. Baby care companies employ LSR for bath mats, toy squeakers, and hygiene product applications.

Travel & Portable Products Travel product manufacturers utilize Food Grade LSR for portable accessories, travel feeding, and mobility products requiring travel specifications. Baby gear companies employ LSR for collapsible products, travel containers, and portable feeding applications.

Educational & Learning Toys Educational toy manufacturers use Food Grade LSR for learning aids, educational toys, and developmental products requiring educational toy specifications. Learning companies employ LSR for shape sorters, stacking toys, and educational play applications.

Quality Control & Testing Procedures

Comprehensive Quality Assurance Every production batch undergoes extensive testing to ensure compliance with FDA food contact regulations, medical device standards, and international infant safety requirements. Our quality control laboratory employs advanced analytical techniques including biocompatibility testing, migration analysis, and mechanical property evaluation. Food-grade silicone is a non-toxic and high-quality silicone that is safe to contact with edibles and drinks, free from phthalates and other harmful chemicals, BPA-free, and commonly used in baby products like bottle nipples, teething rings, and pacifiers.

Quality assurance procedures include:

- Biocompatibility testing using ISO 10993 standards

- Cytotoxicity evaluation using cell culture methods

- Migration testing using food simulants

- Mechanical property testing using universal testing machine

- Durometer testing using Shore A hardness tester

- Tear resistance testing using trouser tear method

- Thermal analysis using DSC and TGA methods

- Chemical resistance testing using solvent immersion

- Sterilization validation using various methods

- Heavy metal analysis using ICP-MS

- VOC testing using headspace GC-MS

- Microbial testing for sterility confirmation

- Accelerated aging testing under controlled conditions

- Processing performance evaluation using pilot equipment

- FDA food contact compliance verification (21CFR177.2600)

- USP Class VI biological reactivity testing

Application Guidelines & Best Practices

Liquid Injection Molding Guidelines Establish proper LIM procedures for Food Grade LSR including temperature control, mold design, and processing parameters for optimal baby product quality and production efficiency in infant care applications.

Sterilization & Safety Procedures Develop appropriate sterilization methods including steam autoclave, EtO, and gamma radiation for maximum safety performance and product sterility in baby care applications.

Storage & Handling Procedures Implement proper storage conditions including temperature control, moisture protection, and contamination prevention for maintaining LSR quality and processing performance throughout storage periods.

For comprehensive information about food-grade silicone properties, safety standards, and baby product applications, you can reference this detailed guide on food-grade silicone which provides extensive coverage of FDA regulations, safety certifications, and applications in baby products including bottle nipples, pacifiers, and infant care items.

Market Applications & Industry Trends

Baby Care Industry Growth Expanding infant care demand and growing premium baby product markets drive continued growth in medical-grade LSR applications for nipples, pacifiers, and baby care products across global infant care operations.

Medical Device Market Expansion Growing pediatric healthcare and expanding medical device complexity support increased adoption of medical-grade LSR for devices, components, and pediatric medical applications worldwide.

Safety Standards Development Expanding safety regulations and growing parental awareness drive growth in certified LSR applications and compliant baby product solutions.

Environmental & Regulatory Compliance

FDA Food Contact Standards & Certifications Food Grade LSR complies with FDA food contact regulations (21CFR177.2600), CPSC baby product safety standards, and international infant safety guidelines ensuring safe use in baby feeding and infant care applications.

Medical Device Standards & Safety Adherence to ISO 10993 biocompatibility standards, USP Class VI requirements, and international medical device guidelines supports responsible use in pediatric medical devices and healthcare applications.

International Baby Product Standards Compliance with ASTM toy safety standards, EN baby product regulations, and international infant safety guidelines ensures appropriate use in baby care and child safety applications.

Performance Advantages & Technical Benefits

✔ Superior Biocompatibility – USP Class VI and ISO 10993 certified for safe infant contact

✔ Ultra-Soft Touch – Natural skin-like feel for comfortable baby interaction

✔ Exceptional Tear Resistance – Outstanding durability for baby use and handling

✔ BPA & Phthalate Free – Completely non-toxic formulation for infant safety

✔ Temperature Resistance – Safe from freezer to boiling water sterilization

✔ Chemical Resistance – Resistance to cleaning agents and sterilization chemicals

✔ Hypoallergenic Properties – Non-allergenic for sensitive infant skin

✔ Easy Sterilization – Compatible with all standard sterilization methods

✔ Odor & Taste Free – Neutral properties that won’t affect feeding experience

✔ Long-Term Stability – Maintains properties throughout product lifecycle

✔ Processing Versatility – Suitable for various molding and manufacturing processes

✔ Transparency Options – Available in clear and colored formulations

Our Food Grade Liquid Silicone Rubber products represent industry-leading standards in medical grade elastomer technology and infant safety solutions, specifically formulated for demanding baby product operations, medical device applications, pediatric care products, and specialized infant safety applications. We provide comprehensive technical support, processing guidance, and regulatory consultation to ensure optimal performance across your specialized baby care, medical device, pediatric, or infant safety applications.

For detailed specifications, technical data sheets, or application-specific recommendations, contact our specialized medical materials division. We offer complete support including processing optimization, regulatory guidance, and technical consultation to maximize effectiveness in your baby care, medical device, pediatric, or infant safety applications.

For more information about our products, feel free to Contact Us today.

Reviews

There are no reviews yet.