HYDROXAMIC ACID

Hydroxamic Acid

High-Performance Flotation Collector & Metal Chelating Agent – Specialized Mining Chemical for Selective Mineral Recovery

Hydroxamic Acid is a specialized organic collector extensively utilized in mineral flotation processes, metal chelation applications, and chemical synthesis operations. Our technical-grade hydroxamic acid delivers exceptional selectivity and collection performance with superior metal-binding characteristics for demanding mining operations and chemical processing applications requiring precise mineral separation and metal recovery.

✅ High-Performance Collector – Superior Selectivity & Metal Binding Capacity

✅ Organic Functional Group – Excellent Chelation & Complex Formation Properties

✅ Mining, Chemical Processing & Pharmaceutical Grades Available

✅ Various CAS Numbers – Multiple Hydroxamic Acid Derivatives Available

✅ Mineral Flotation, Metal Extraction, Chemical Synthesis, Pharmaceutical Applications

Advanced Hydroxamic Acid Collectors for Selective Mineral Flotation & Metal Processing

Hydroxamic acids are a class of organic compounds having the general formula R−C(=O)−N(−OH)−R’ bearing the functional group −C(=O)−N(−OH)−, where R and R’ are typically organyl groups or hydrogen. These versatile chemical compounds serve critical functions across mineral processing operations, metal extraction processes, pharmaceutical manufacturing, and specialized chemical applications requiring selective metal chelation and superior flotation performance.

At Chemicals & Process Equipment Limited, we supply high-grade Hydroxamic Acid derivatives manufactured under stringent quality control standards and international specifications. Our comprehensive product range includes flotation collector grade, pharmaceutical grade, and specialized formulations meeting diverse requirements for mineral processing, metal extraction, chemical synthesis, and pharmaceutical applications across global mining and chemical markets.

✅ Flotation Collector Excellence – Optimized Metal Binding for Selective Mineral Recovery

✅ Consistent Purity Standards – >95% Purity with Comprehensive Quality Documentation

✅ Superior Chelation Properties – Enhanced Metal Ion Binding & Processing Efficiency

✅ Multi-Application Performance – Mining, Metal Processing, Chemical & Pharmaceutical Applications

✅ Technical Support Package – Complete Application Guidance & Process Optimization

For comprehensive information on hydroxamic acid applications in mineral processing and flotation chemistry, refer to this detailed flotation collectors guide by ScienceDirect. Our flotation chemicals portfolio provides specialized guidance for optimal mineral processing performance across diverse mining applications.

Since hydroxamate was first used as a collector for metal oxide flotation, the use of alkyl hydroxamate as a collector in numerous flotation systems has been studied extensively. This advanced chemical functionality provides superior selectivity for oxide minerals, rare earth elements, and complex metallic ores requiring precise separation chemistry and enhanced recovery performance.

Technical Specifications & Chemical Properties

| Property | Flotation Collector Grade | Pharmaceutical Grade | Chemical Synthesis Grade |

|---|---|---|---|

| General Formula | R-CO-NHOH | R-CO-NHOH | R-CO-NHOH |

| Functional Group | −C(=O)−N(−OH)− | −C(=O)−N(−OH)− | −C(=O)−N(−OH)− |

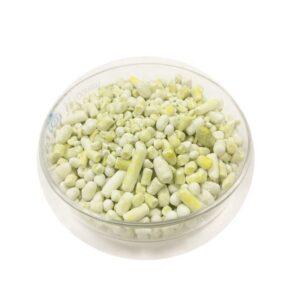

| Appearance | White to off-white solid | White crystalline solid | White to light yellow solid |

| Purity | ≥95.0% | ≥98.0% | ≥99.0% |

| pKa Range | 7.05-11.33 | 7.05-11.33 | 7.05-11.33 |

| Melting Point | Varies by derivative | Varies by derivative | Varies by derivative |

| Solubility (Water) | Moderate | Moderate | Moderate |

| pH (1% solution) | 7.0-9.0 | 7.0-8.5 | 7.0-9.0 |

| Moisture Content | <0.5% | <0.2% | <0.1% |

| Heavy Metals | <10 ppm | <5 ppm | <2 ppm |

| Residue on Ignition | <0.2% | <0.1% | <0.05% |

| Metal Chelation Capacity | High | High | Very High |

| Selectivity Index | Excellent | Excellent | Superior |

| Packaging Options | 25kg drums, 50kg drums, custom packaging |

Common Hydroxamic Acid Derivatives:

- Acetohydroxamic Acid (CAS 546-88-3)

- Octanohydroxamic Acid (CAS 7377-03-9)

- Benzohydroxamic Acid (CAS 495-18-1)

- Salicylhydroxamic Acid (CAS 89-73-6)

- Custom alkyl and aryl derivatives available

Specialized Packaging Solutions:

- 25kg fiber drums with polyethylene liner

- 50kg steel drums with chemical-resistant coating

- Custom packaging for laboratory and pilot-scale applications

- Bulk packaging for large-scale industrial operations

- Inert atmosphere packaging for sensitive derivatives

Mineral Flotation & Mining Applications

Oxide Mineral Flotation Hydroxamic acids demonstrate exceptional performance in flotation of scheelite, wolframite and cassiterite, with recoveries exceeding 90-97% for tungsten and tin oxide minerals. Mining operations utilize hydroxamic acid collectors for selectively recovering oxide minerals including iron ore, manganese ore, and rare earth minerals requiring specialized flotation chemistry.

Rare Earth Element Recovery Collectors such as fatty acids, phosphonic acids, and hydroxamic acids are necessary for rare earth mineral flotation, with hydroxamic acids providing superior selectivity for bastnaesite, monazite, and xenotime flotation in complex rare earth ore processing operations.

Tungsten Mineral Concentration Novel hydroxamic acid collectors with dual hydroxamic groups enhance the interaction between collector molecules and wolframite minerals, enabling efficient tungsten recovery without traditional lead activation requirements in environmentally sustainable processing operations.

Tin Mineral Processing Hydroxamic acid collectors for cassiterite separation demonstrate superior collection performance through rational molecular design incorporating functional group enhancement and optimized carbon chain structures for improved tin mineral recovery.

Copper Oxide Flotation Novel hydroxamic acid collectors demonstrate excellent flotation separation of malachite against quartz, providing enhanced selectivity and recovery performance for copper oxide mineral processing in complex ore bodies.

Metal Extraction & Hydrometallurgy Applications

Selective Metal Ion Chelation The metal chelating properties of hydroxamic acids make them valuable compounds for metal extraction applications, providing selective binding with various metal ions including iron, copper, nickel, and rare earth elements in hydrometallurgical processing operations.

Solvent Extraction Processes Hydrometallurgical operations employ hydroxamic acids as extractants for selective metal recovery from leach solutions, providing enhanced separation efficiency and metal purity in solvent extraction circuits.

Metal Purification Applications Chemical processing facilities utilize hydroxamic acids for removing metal impurities from process solutions, achieving high-purity metal products and meeting stringent quality specifications.

Environmental Metal Recovery Waste treatment operations employ hydroxamic acid chemistry for recovering valuable metals from industrial waste streams, electronic waste, and contaminated waters requiring selective metal extraction.

Chemical Synthesis & Manufacturing Applications

Pharmaceutical Intermediate Production Hydroxamic acid-based compounds have gained significant attention in medicinal chemistry applications, serving as key intermediates in pharmaceutical manufacturing for producing enzyme inhibitors, anticancer agents, and antimicrobial compounds.

Specialty Chemical Manufacturing Chemical synthesis operations utilize hydroxamic acids as building blocks for producing chelating agents, corrosion inhibitors, and functional materials requiring specific metal-binding characteristics.

Polymer Chemistry Applications Hydroxamic acids feature numerous applications in polymer science, providing metal coordination sites for producing metallic polymers, functional materials, and advanced composite systems.

Analytical Chemistry Reagents Laboratory applications employ hydroxamic acids as analytical reagents for metal determination, colorimetric analysis, and spectroscopic applications requiring selective metal complexation.

Pharmaceutical & Biomedical Applications

Drug Development Applications Three hydroxamic acid-based HDAC inhibitors have been approved as anticancer drugs, demonstrating the pharmaceutical importance of hydroxamic acid functionality in modern drug development and therapeutic applications.

Enzyme Inhibitor Development Pharmaceutical research utilizes hydroxamic acids for developing enzyme inhibitors targeting metalloenzymes, providing therapeutic applications in cancer treatment, infectious diseases, and metabolic disorders.

Antimicrobial Agent Production Hydroxamic acids show antifungal activities in complexes with several metals, enabling development of antimicrobial formulations and therapeutic agents for infectious disease treatment.

Bioconjugation Applications Biotechnology applications employ hydroxamic acids for protein modification, drug conjugation, and targeted therapy development requiring specific metal coordination chemistry.

Industrial Processing Applications

Corrosion Inhibitor Formulations Industrial maintenance utilizes hydroxamic acids in corrosion inhibitor formulations, providing metal surface protection through chelation mechanisms in various industrial environments.

Metal Surface Treatment Manufacturing operations employ hydroxamic acids for metal surface preparation, cleaning applications, and surface modification processes requiring controlled metal interaction.

Catalysis Applications Chemical processing utilizes hydroxamic acid-metal complexes as catalysts for various organic transformations, providing enhanced reaction selectivity and efficiency.

Water Treatment Applications Industrial water treatment employs hydroxamic acids for selective metal removal, achieving regulatory compliance and process optimization in metal-containing waste streams.

Quality Control & Analytical Testing

Comprehensive Quality Assurance Every production batch undergoes extensive analytical testing to ensure compliance with flotation collector, pharmaceutical, and chemical synthesis grade specifications. Our quality control laboratory employs advanced analytical techniques including HPLC, NMR spectroscopy, and metal analysis.

Quality assurance procedures include:

- Purity determination via high-performance liquid chromatography

- Structural confirmation through NMR spectroscopy analysis

- Metal content analysis using atomic absorption spectroscopy

- Moisture content determination via Karl Fischer titration

- Melting point verification through differential scanning calorimetry

- Chelation capacity testing through metal binding studies

- Microbiological testing for pharmaceutical grade materials

- Flotation performance evaluation in laboratory testing

Application Guidelines & Best Practices

Flotation Dosage Optimization Optimal hydroxamic acid dosing in mineral flotation typically ranges from 50-500 g/tonne of ore processed, depending on mineral type, ore characteristics, and desired selectivity for specific metal recovery objectives.

pH Control Requirements The pKa of hydroxamic acid ranges from 7.05 to 11.33 depending on chemical structure, requiring careful pH control for optimal performance in flotation and metal extraction applications.

Storage & Handling Considerations Hydroxamic acids require protection from moisture, light, and oxidation to maintain chemical stability and performance characteristics in industrial applications.

Market Applications & Industry Trends

Growing Rare Earth Demand Increasing demand for rare earth elements in renewable energy, electronics, and advanced materials drives sustained growth in hydroxamic acid collector applications for specialized mineral processing operations.

Pharmaceutical Industry Expansion The approval of hydroxamic acid-based pharmaceutical compounds supports continued growth in pharmaceutical-grade hydroxamic acid applications for drug development and manufacturing.

Environmental Regulations Stricter environmental regulations drive demand for selective collectors that eliminate toxic reagents while maintaining superior flotation performance and environmental compliance.

Performance Advantages & Technical Benefits

✔ Superior Selectivity – Exceptional mineral separation and metal binding characteristics

✔ Environmental Compatibility – Reduced toxicity compared to traditional collectors

✔ pH Flexibility – Wide operating pH range for diverse applications

✔ Chemical Stability – Consistent performance under varying process conditions

✔ Multi-Functionality – Flotation, extraction, and pharmaceutical applications

✔ Technical Excellence – Advanced molecular design for optimal performance

✔ Regulatory Compliance – Meeting international safety and quality standards

Our Hydroxamic Acid products represent cutting-edge technology in selective mineral processing and metal extraction applications, specifically formulated for demanding mining operations, chemical processing, and pharmaceutical manufacturing. We provide comprehensive technical support, process optimization guidance, and regulatory compliance assistance to ensure optimal performance across your specialized flotation, extraction, or chemical synthesis applications.

For detailed specifications, flotation performance data, or pharmaceutical-grade documentation, contact our specialized mining and pharmaceutical chemicals division. We offer complete support including process optimization, metallurgical testing, and regulatory compliance assistance to maximize effectiveness in your mineral processing, metal extraction, or pharmaceutical manufacturing applications.

Reviews

There are no reviews yet.