HYDROCHLORIC ACID

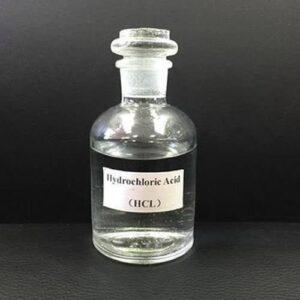

Hydrochloric Acid (HCl)

Technical Grade Strong Acid & Industrial Processing Agent – Specialized Chemical for Manufacturing & Metal Treatment

Hydrochloric Acid is a highly corrosive strong acid extensively utilized in metal treatment processes, chemical manufacturing, pH control systems, and industrial cleaning operations. Our technical-grade hydrochloric acid delivers exceptional chemical reactivity and consistent performance with reliable purity for demanding industrial applications, water treatment, and chemical processing operations.

✅ Technical Grade Strong Acid – Superior Chemical Reactivity & Process Control

✅ Clear Colorless Solution – High Purity & Consistent Concentration Performance

✅ Industrial, Electronic & Food Processing Grades Available

✅ CAS 7647-01-0 Certified – International Quality Standards

✅ Metal Treatment, Chemical Manufacturing, Water Treatment, pH Control Applications

High-Performance Hydrochloric Acid for Industrial Manufacturing & Chemical Processing Operations

Hydrochloric acid (HCl), historically called muriatic acid, is a strong mineral acid solution of hydrogen chloride in water. It is a highly corrosive, strong mineral acid with many industrial uses among which are removing rust from iron and steel before hot dip galvanizing, for pH control of solutions, and for regenerating ion exchange resins. This versatile chemical compound serves critical functions across metal processing operations, chemical manufacturing, water treatment systems, and specialized industrial applications requiring controlled acidity and reliable chemical reactivity.

At Chemicals & Process Equipment Limited, we supply high-grade Hydrochloric Acid manufactured under stringent quality control standards and international specifications. Our comprehensive product range includes industrial grade, electronic grade, food processing grade, and specialized formulations meeting diverse requirements for metal treatment, chemical synthesis, water treatment, and industrial processing across global manufacturing and chemical markets.

✅ Industrial Processing Excellence – Optimized Acidity & Chemical Reactivity for Manufacturing Operations

✅ Consistent Purity Standards – Multiple Concentration Grades with Comprehensive Quality Documentation

✅ Superior Corrosion Properties – Enhanced Metal Treatment & Chemical Processing Efficiency

✅ Multi-Application Performance – Metal Treatment, Chemical Manufacturing, Water Treatment & Electronics

✅ Technical Support Package – Complete Application Guidance & Process Optimization

For comprehensive information on hydrochloric acid applications in industrial processing and chemical manufacturing, refer to this detailed industrial acids guide by EPA. Our industrial chemicals portfolio provides specialized guidance for optimal manufacturing and chemical processing performance across diverse industrial applications.

Hydrochloric acid has the empirical formula HCl with a molar mass of 36.46 g/mol, existing as a colorless aqueous solution with properties varying according to concentration. Concentrated grades are considered 35-38 wt% HCl and are classified as fuming hydrochloric acid due to the release of HCl gas from the solution.

Technical Specifications & Chemical Properties

| Property | Industrial Grade 31% | Technical Grade 37% | Electronic Grade |

|---|---|---|---|

| Chemical Formula | HCl | HCl | HCl |

| CAS Number | 7647-01-0 | 7647-01-0 | 7647-01-0 |

| IUPAC Name | Hydrogen chloride | Hydrogen chloride | Hydrogen chloride |

| Molecular Weight | 36.46 g/mol | 36.46 g/mol | 36.46 g/mol |

| Appearance | Clear colorless liquid | Clear colorless liquid | Clear colorless liquid |

| Concentration | 30-32% HCl | 36-38% HCl | 36-38% HCl |

| Specific Gravity | 1.15-1.16 | 1.18-1.19 | 1.18-1.19 |

| pH Value | <1.0 | <0.5 | <0.5 |

| Boiling Point | 110°C (31%) | 108°C (37%) | 108°C (37%) |

| Melting Point | -26°C (31%) | -30°C (37%) | -30°C (37%) |

| Vapor Pressure | High | Very High | Very High |

| Iron (Fe) Content | <50 ppm | <10 ppm | <1 ppm |

| Sulfates (as SO₄) | <100 ppm | <50 ppm | <10 ppm |

| Heavy Metals (as Pb) | <10 ppm | <5 ppm | <1 ppm |

| Chlorides (as Cl₂) | <10 ppm | <5 ppm | <1 ppm |

| Residue on Ignition | <0.05% | <0.02% | <0.005% |

| Packaging Options | 35kg drums, 200L drums, 1000L IBCs, bulk tankers |

Specialized Packaging Solutions:

- 35kg polyethylene containers with chemical-resistant properties

- 200L high-density polyethylene drums with secure closures

- 1000L intermediate bulk containers (IBCs) with corrosion-resistant fittings

- Bulk tanker deliveries for large-scale industrial operations

- Laboratory packaging from 500mL to 25L containers

- Custom packaging solutions for specialized applications

Metal Treatment & Processing Applications

Steel Pickling Operations Hydrochloric acid is extensively used in pickling and cleaning operations for metal treatment, where steel manufacturing facilities utilize HCl for removing oxide scale, rust, and surface contaminants from steel products before galvanizing, coating, or further processing operations.

Metal Surface Preparation Industrial metal processing operations employ hydrochloric acid for surface preparation, descaling, and cleaning applications, achieving optimal surface conditions for welding, painting, and protective coating applications.

Galvanizing Pre-Treatment Hot-dip galvanizing facilities use hydrochloric acid for pre-treatment cleaning, ensuring proper zinc adhesion and coating quality in steel galvanizing operations requiring superior surface preparation.

Stainless Steel Passivation Stainless steel manufacturing utilizes hydrochloric acid for passivation treatments, removing free iron contamination and enhancing corrosion resistance in precision stainless steel applications.

Ore Refining & Metal Production Mining and metallurgical operations employ hydrochloric acid for refining ore and producing metals like tantalum and tin, providing essential chemical processing for metal extraction and purification applications.

Chemical Manufacturing & Processing Applications

Chloride Production & Chemical Synthesis Chemical manufacturing facilities utilize hydrochloric acid for production of chlorides, fertilizers, and dyes, serving as a key raw material in diverse chemical synthesis operations requiring reliable acid chemistry.

Pharmaceutical Manufacturing Pharmaceutical industries heavily rely on hydrochloric acid for various manufacturing applications, including API synthesis, pH adjustment, and chemical processing operations requiring pharmaceutical-grade acid quality.

Organic Chemical Synthesis Chemical processing operations employ hydrochloric acid as a catalyst and reagent in organic synthesis reactions, providing controlled acidity for esterification, alkylation, and hydrolysis reactions.

Polymer Production Applications Polymer manufacturing utilizes hydrochloric acid for monomer synthesis, polymerization catalysis, and chemical processing operations requiring precise pH control and chemical reactivity.

Ion Exchange Resin Regeneration Water treatment and chemical processing facilities use hydrochloric acid for regenerating cation exchange resins, restoring ion exchange capacity in water softening and chemical separation applications.

Water Treatment & pH Control Applications

Municipal Water Treatment Water processing operations extensively utilize hydrochloric acid for pH adjustment, alkalinity control, and chemical neutralization in municipal and industrial water treatment systems.

Industrial pH Control Systems Process industries use hydrochloric acid for essential pH control applications, maintaining optimal chemical conditions in manufacturing processes, cooling systems, and chemical processing operations.

Neutralization Applications Industrial facilities employ hydrochloric acid for neutralizing basic solutions, achieving chemical balance and regulatory compliance in waste treatment and chemical processing applications.

Swimming Pool Water Treatment Swimming pool maintenance operations utilize hydrochloric acid for pH reduction, alkalinity adjustment, and water chemistry balance in commercial and residential pool applications.

Boiler Water Treatment Industrial steam generation facilities use hydrochloric acid for boiler cleaning, scale removal, and water chemistry control, preventing corrosion and maintaining efficient heat transfer.

Electronic & Semiconductor Applications

Electronic Grade Processing The electronic grade hydrochloric acid market is projected to reach $4.35 billion by 2032, exhibiting 11.5% CAGR, driven by semiconductor manufacturing demand for ultra-pure acid in wafer processing and electronic component production.

Semiconductor Wafer Cleaning Semiconductor manufacturing facilities utilize electronic-grade hydrochloric acid for wafer cleaning, etching, and surface preparation operations requiring ultra-high purity and minimal contaminant levels.

Printed Circuit Board Manufacturing Electronics manufacturing operations employ hydrochloric acid for PCB etching, surface preparation, and metal plating applications in electronic circuit production processes.

Solar Panel Production Photovoltaic manufacturing utilizes hydrochloric acid for silicon wafer texturing, surface cleaning, and chemical processing operations in solar cell production applications.

Food Processing & Industrial Applications

Food Processing Operations Food processing industries heavily rely on hydrochloric acid for various applications including pH adjustment, equipment cleaning, and chemical processing operations requiring food-grade acid quality.

Gelatin Manufacturing Food ingredient production utilizes hydrochloric acid for gelatin processing, protein hydrolysis, and pH control applications in food additive manufacturing operations.

Corn Syrup Production Corn processing facilities use hydrochloric acid for starch hydrolysis, syrup clarification, and pH control in high fructose corn syrup production applications.

Equipment Sanitization Food processing facilities utilize hydrochloric acid for equipment cleaning and sanitization operations, ensuring food safety and hygiene standards in food manufacturing environments.

Petroleum & Refining Applications

Oil Refining Operations Oil refining industries heavily rely on hydrochloric acid for catalyst regeneration, chemical processing, and refinery operations requiring controlled acidity and chemical reactivity.

Well Acidizing Applications Oil and gas production utilizes hydrochloric acid for well stimulation, formation cleaning, and enhanced oil recovery operations in petroleum extraction applications.

Catalyst Regeneration Petrochemical facilities employ hydrochloric acid for catalyst regeneration, chemical cleaning, and process optimization in refinery and chemical processing operations.

Specialty Industrial Applications

Textile Industry Processing Textile manufacturing operations utilize hydrochloric acid for fiber processing, dye applications, and chemical treatment operations requiring controlled acidity and processing characteristics.

Leather Processing Applications Leather manufacturing facilities use hydrochloric acid for hide processing, tanning operations, and pH control applications in traditional leather production processes.

Rubber Manufacturing Rubber processing operations employ hydrochloric acid for latex coagulation, chemical processing, and manufacturing applications requiring controlled chemical conditions.

Glass & Ceramics Production Glass manufacturing utilizes hydrochloric acid for surface etching, chemical processing, and specialty glass production requiring controlled acid chemistry.

Grade Classifications & Quality Standards

Industrial Grade (31-32%) Industrial-grade hydrochloric acid provides high-performance solutions for metal treatment, industrial cleaning, water processing, and chemical manufacturing, offering cost-effective acid chemistry for general industrial applications.

Technical Grade (37%) Technical Grade Hydrochloric Acid delivers exceptional industrial performance through its optimized 37% concentration, providing unparalleled chemical reactivity and reliable process control for demanding chemical processing applications.

Electronic Grade Electronic-grade hydrochloric acid meets stringent purity requirements for semiconductor manufacturing and electronic component production, ensuring ultra-low contaminant levels and consistent performance.

Food Processing Grade Food-grade hydrochloric acid complies with food safety regulations and quality standards for food processing applications, ensuring product safety and regulatory compliance.

Storage & Handling Requirements

Corrosion-Resistant Storage

- Hydrochloric acid requires careful handling and engineered storage systems due to its highly corrosive nature

- Use corrosion-resistant materials including high-density polyethylene, PVC, or specialized alloys

- Implement proper ventilation systems to control vapor exposure and prevent corrosion

- Maintain temperature control to minimize vapor generation and material degradation

- Establish leak detection and containment systems for emergency response

Safety Precautions

- Utilize comprehensive personal protective equipment including acid-resistant clothing and respiratory protection

- Implement stringent safety precautions and precise measurement instruments to ensure safety and efficiency

- Follow established procedures for material transfer and handling operations

- Maintain proper training programs for personnel handling corrosive chemicals

- Establish emergency response procedures for spill containment and exposure incidents

Quality Control & Analytical Testing

Comprehensive Quality Assurance Every production batch undergoes extensive analytical testing to ensure compliance with industrial, electronic, and food processing grade specifications. Our quality control laboratory employs advanced analytical techniques including titration analysis, atomic absorption spectroscopy, and purity testing.

Quality assurance procedures include:

- Concentration determination via acid-base titration analysis

- Iron content analysis using atomic absorption spectroscopy

- Heavy metals testing through inductively coupled plasma analysis

- Sulfate content determination via gravimetric analysis

- Residue on ignition testing through standardized procedures

- Chlorine content analysis using ion chromatography

- Microbiological testing for food grade applications

- Particle analysis for electronic grade specifications

Application Guidelines & Best Practices

Concentration Selection Guidelines Optimal hydrochloric acid concentration selection depends on specific application requirements, with 31% grade suitable for general industrial applications and 37% grade preferred for demanding chemical processing operations.

Dilution Procedures When diluting concentrated hydrochloric acid, always add acid to water slowly while stirring to prevent violent exothermic reactions and ensure operator safety during preparation procedures.

Safety Considerations Handling hydrochloric acid requires stringent precautions due to its strong corrosive properties, necessitating comprehensive safety protocols, proper ventilation, and emergency response procedures.

Market Applications & Industry Trends

Growing Electronic Industry Demand The electronic grade hydrochloric acid market demonstrates significant growth potential with projected 11.5% CAGR, driven by semiconductor manufacturing expansion and electronic device production growth.

Industrial Manufacturing Growth Expanding industrial manufacturing activities and infrastructure development support continued growth in hydrochloric acid applications across metal processing, chemical manufacturing, and water treatment sectors.

Environmental Compliance Focus Stricter environmental regulations drive demand for high-purity hydrochloric acid that minimizes environmental impact while maintaining superior processing performance and regulatory compliance.

Regulatory Compliance & Safety Information

International Standards Compliance Our hydrochloric acid products comply with international standards including ASTM, ISO, and regional industrial specifications, ensuring global regulatory acceptance for industrial and electronic applications.

Transportation Classification Hydrochloric acid is classified as UN1789 (Corrosive Liquid) requiring appropriate packaging, labeling, and transportation procedures according to international dangerous goods regulations.

Environmental Regulations Manufacturing and handling operations maintain compliance with environmental regulations regarding emissions control, waste management, and occupational safety requirements.

Performance Advantages & Technical Benefits

✔ Superior Chemical Reactivity – Exceptional acid strength for optimal processing performance

✔ Purity Leadership – Multiple grade specifications ensuring consistent processing results

✔ Application Versatility – Metal treatment, chemical processing, electronics & food applications

✔ Quality Consistency – Rigorous testing ensures reliable batch-to-batch performance

✔ Technical Expertise – Comprehensive application support and process optimization

✔ Global Supply Chain – Reliable availability supporting international operations

✔ Safety Documentation – Complete regulatory compliance and safety data packages

Our Hydrochloric Acid products represent industry-leading standards in strong acid chemistry and industrial processing applications, specifically formulated for demanding manufacturing operations, metal treatment, and chemical processing. We provide comprehensive technical support, process optimization guidance, and safety documentation to ensure optimal performance across your specialized industrial, electronic, or chemical processing applications.

For detailed specifications, application performance data, or safety documentation, contact our specialized industrial chemicals division. We offer complete support including process optimization, application testing, and regulatory compliance assistance to maximize effectiveness in your metal treatment, chemical manufacturing, water treatment, or electronic processing applications.

Reviews

There are no reviews yet.