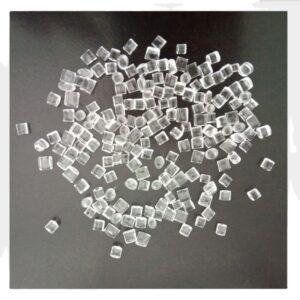

EPS Expandable Polystyrene Beads

EPS Expandable Polystyrene Beads

Premium Quality EPS Expandable Polystyrene Beads – Lightweight Foam Material for Construction Insulation, Packaging Applications, Building Materials & Industrial Uses

EPS Expandable Polystyrene Beads are high-performance expandable foam materials extensively utilized in construction insulation, protective packaging applications, building insulation, and industrial foam products requiring superior thermal insulation, shock absorption, and exceptional lightweight properties.

✅ Ultra-High Performance EPS Beads – Superior Insulation & Multi-Industry Foam Performance

✅ Multiple Density Options – Steam Molding, Block Molding, Shape Molding, Construction Grade for Specialized Applications

✅ Excellent Thermal Insulation – Lightweight, Flame Retardant Options for Optimal Building Performance

✅ Multi-Industry Compatible – Enhanced Construction, Packaging, Insulation & Industrial Properties

✅ Building Insulation, Protective Packaging, Construction Blocks & Molded Foam Products Applications

High-Quality EPS Expandable Polystyrene Beads

EPS Expandable Polystyrene Beads represent advanced expandable foam technology specifically formulated for construction insulation, protective packaging applications, building materials, and industrial operations requiring exceptional thermal insulation, lightweight properties, and multi-industry effectiveness. This essential expandable polystyrene serves critical functions across building construction, packaging systems, insulation applications, and specialized foam manufacturing requiring controlled expansion, thermal resistance, and processing capabilities with exceptional reliability.

At Chemicals & Process Equipment Limited, we supply high-performance EPS Expandable Polystyrene Beads manufactured under stringent quality control standards and international building and packaging specifications. Our comprehensive product range includes construction grades, packaging grades, insulation formulations, and custom density options meeting diverse requirements for building manufacturing, packaging applications, insulation systems, and specialized foam solutions across global construction, packaging, insulation, and industrial markets.

✅ Advanced Expandable Foam Technology – Optimized Processing Properties & Multi-Industry Performance

✅ Consistent Quality Standards – Multiple Density Grade Classifications with Comprehensive Documentation

✅ Essential Expandable Polystyrene – Superior Construction, Packaging & Insulation Performance

✅ Multi-Industry Applications – Construction, Packaging, Insulation & Industrial Systems

✅ Technical Support Package – Complete Application Guidance & Performance Optimization

The global expanded polystyrene market size was valued at USD 11.32-18.3 billion in 2024 and is projected to reach USD 24.93-36.3 billion by 2033, growing at a CAGR of 4.8-8.54% during the forecast period, while the market is expected to reach 12.84-14.92 million tons by 2025-2030. This growth is driven by increasing construction demand, expanding packaging applications, growing insulation requirements, and rising industrial foam applications across global building and packaging markets.

Technical Specifications & EPS Expandable Polystyrene Beads Properties

| Property | Low Density Grade | Medium Density Grade | High Density Grade | Flame Retardant Grade |

|---|---|---|---|---|

| Bead Size (mm) | 0.5-2.0 | 0.8-3.0 | 1.0-4.0 | 0.6-2.5 |

| Bulk Density (kg/m³) | 10-20 | 15-30 | 20-50 | 12-25 |

| Expansion Ratio | 40-60:1 | 25-45:1 | 15-35:1 | 35-55:1 |

| Final Density (kg/m³) | 10-25 | 15-35 | 25-50 | 12-30 |

| Compressive Strength (kPa) | 70-150 | 100-250 | 200-400 | 80-180 |

| Tensile Strength (kPa) | 150-300 | 200-400 | 300-600 | 180-350 |

| Flexural Strength (kPa) | 200-400 | 250-500 | 400-800 | 220-450 |

| Thermal Conductivity (W/m·K) | 0.030-0.038 | 0.032-0.040 | 0.035-0.045 | 0.031-0.039 |

| Service Temperature (°C) | -40 to +80 | -40 to +80 | -40 to +80 | -40 to +80 |

| Water Absorption (%) | 1-3 | 1-4 | 2-5 | 1-3 |

| Dimensional Stability (%) | ±1-2 | ±1-3 | ±2-4 | ±1-2 |

| Cell Structure | Closed cell (95-98%) | Closed cell (95-98%) | Closed cell (95-98%) | Closed cell (95-98%) |

| Flame Resistance | Self-extinguishing | Self-extinguishing | Self-extinguishing | Enhanced FR |

| Pre-expansion Temperature (°C) | 90-100 | 95-105 | 100-110 | 92-102 |

| Pre-expansion Time (min) | 3-8 | 4-10 | 5-12 | 3-9 |

| Molding Temperature (°C) | 100-120 | 105-125 | 110-130 | 102-122 |

| Molding Pressure (kPa) | 20-50 | 30-70 | 50-100 | 25-60 |

| Aging Time (hours) | 12-24 | 18-36 | 24-48 | 12-30 |

| Moisture Content (%) | <0.5 | <0.5 | <0.5 | <0.5 |

| Pentane Content (%) | 4-8 | 5-9 | 6-10 | 4-8 |

| Bead Shape | Spherical | Spherical | Spherical | Spherical |

| Color | White/Natural | White/Natural | White/Natural | White/Grey |

| Processing Method | Steam molding, block molding, shape molding | |||

| Recyclability | Recyclable | Recyclable | Recyclable | Recyclable |

| Storage Conditions | Cool, dry, ventilated environment | |||

| Shelf Life | 6-12 months | |||

| Packaging Options | 25kg bags, 500kg big bags, bulk containers |

Available Grade Types:

- Construction Grade for building insulation applications

- Packaging Grade for protective packaging solutions

- Insulation Grade for thermal insulation systems

- Flame Retardant Grade for fire safety applications

- High Density Grade for structural applications

- Low Density Grade for lightweight applications

- Food Contact Grade for food packaging applications

- Marine Grade for marine and water applications

- Automotive Grade for vehicle applications

- Custom Grades for specialized requirements

Specialized Processing Solutions:

- Steam chest molding for blocks and shapes

- Automatic molding for high-volume production

- Continuous block molding for large panels

- Shape molding for complex geometries

- Pre-expansion systems for bead preparation

- Aging systems for bead stabilization

- Cutting systems for final dimensions

- Recycling systems for waste processing

Construction & Building Applications

Building Insulation Systems Construction manufacturers utilize EPS Expandable Polystyrene Beads for wall insulation, roof insulation, and building envelope requiring construction specifications. Building companies employ EPS beads for thermal barriers, energy efficiency, and insulation system applications.

Foundation & Below-Grade Insulation Foundation manufacturers use EPS Expandable Polystyrene Beads for foundation walls, basement insulation, and below-grade applications requiring foundation specifications. Construction companies employ EPS beads for moisture resistance, structural support, and foundation insulation applications.

Roof & Attic Insulation Roofing manufacturers utilize EPS Expandable Polystyrene Beads for flat roofs, pitched roofs, and attic insulation requiring roofing specifications. Building companies employ EPS beads for thermal performance, weather resistance, and roof insulation applications.

Structural Insulated Panels (SIPs) Panel manufacturers use EPS Expandable Polystyrene Beads for SIP cores, structural panels, and prefab construction requiring panel specifications. Building system companies employ EPS beads for load-bearing capacity, insulation performance, and structural panel applications.

Packaging & Protection Applications

Electronic & Fragile Item Packaging Packaging manufacturers utilize EPS Expandable Polystyrene Beads for electronics protection, fragile item packaging, and shock absorption requiring protective packaging specifications. Electronics companies employ EPS beads for cushioning systems, impact protection, and electronic packaging applications.

Food & Beverage Packaging Food packaging manufacturers use EPS Expandable Polystyrene Beads for food containers, beverage cups, and thermal packaging requiring food packaging specifications. Food service companies employ EPS beads for temperature retention, food safety, and disposable packaging applications.

Medical & Pharmaceutical Packaging Medical packaging manufacturers utilize EPS Expandable Polystyrene Beads for pharmaceutical shipping, medical device protection, and temperature-sensitive packaging requiring medical packaging specifications. Healthcare companies employ EPS beads for sterile packaging, temperature control, and medical shipping applications.

Industrial & Heavy Equipment Packaging Industrial packaging manufacturers use EPS Expandable Polystyrene Beads for machinery protection, heavy equipment shipping, and industrial packaging requiring industrial specifications. Manufacturing companies employ EPS beads for vibration damping, impact protection, and industrial packaging applications.

Specialized Industrial Applications

Automotive & Transportation Automotive manufacturers utilize EPS Expandable Polystyrene Beads for bumper cores, headrests, and automotive components requiring automotive specifications. Vehicle companies employ EPS beads for crash absorption, weight reduction, and automotive safety applications.

Marine & Water Applications Marine manufacturers use EPS Expandable Polystyrene Beads for flotation devices, marine buoys, and water sports equipment requiring marine specifications. Water companies employ EPS beads for buoyancy systems, water resistance, and marine applications.

Agriculture & Horticulture Agricultural manufacturers utilize EPS Expandable Polystyrene Beads for soil conditioning, growing media, and horticultural applications requiring agricultural specifications. Farming companies employ EPS beads for drainage improvement, root aeration, and growing media applications.

Geotechnical & Civil Engineering Civil engineering manufacturers use EPS Expandable Polystyrene Beads for lightweight fill, road construction, and geotechnical applications requiring civil engineering specifications. Infrastructure companies employ EPS beads for load reduction, settlement control, and civil engineering applications.

Quality Control & Testing Procedures

Comprehensive Quality Assurance Every production batch undergoes extensive testing to ensure compliance with building codes, packaging standards, and international quality requirements. Our quality control laboratory employs advanced analytical techniques including thermal analysis, mechanical testing, and expansion ratio evaluation. Expandable polystyrene consists of polystyrene micro-pellets or beads containing a blowing agent and other additives for foaming, with bead-shaped granules that swell up to 20 to 50 times their volume when heat is applied during pre-foaming.

Quality assurance procedures include:

- Bead size distribution analysis using laser diffraction

- Expansion ratio testing using steam chest method

- Density measurement using displacement method

- Thermal conductivity testing using heat flow meter

- Compressive strength testing using universal testing machine

- Water absorption testing using immersion method

- Dimensional stability testing using controlled conditions

- Flame resistance testing using limiting oxygen index

- Cell structure analysis using microscopy

- Pentane content analysis using gas chromatography

- Moisture content testing using Karl Fischer method

- Processing performance evaluation using pilot equipment

- Aging time optimization using expansion tests

- Building code compliance verification

- Environmental impact assessment using life cycle analysis

- Quality consistency monitoring using statistical process control

Application Guidelines & Best Practices

Pre-expansion Guidelines Establish proper pre-expansion procedures for EPS Beads including steam temperature, timing, and aging requirements for optimal expansion performance and foam quality in construction and packaging applications.

Molding & Processing Methods Develop appropriate molding techniques including pressure control, temperature management, and cooling procedures for maximum product quality and dimensional accuracy in foam manufacturing.

Storage & Handling Procedures Implement proper storage conditions including temperature control, ventilation requirements, and contamination prevention for maintaining EPS bead quality and expansion performance throughout storage periods.

For comprehensive information about expanded polystyrene properties, manufacturing processes, and applications, you can reference this detailed guide on EPS beads and expanded polystyrene which provides extensive coverage of EPS characteristics, benefits, applications in packaging and construction, and environmental considerations.

Market Applications & Industry Trends

Construction Industry Growth Expanding building construction and growing energy efficiency requirements drive continued growth in EPS applications for insulation, structural systems, and building materials across global construction operations.

Packaging Market Expansion Growing e-commerce demand and expanding protective packaging markets support increased adoption of EPS for cushioning, protection, and specialty packaging applications worldwide.

Sustainability Development Expanding recycling initiatives and growing environmental consciousness drive growth in recyclable EPS applications and sustainable foam solutions.

Environmental & Regulatory Compliance

Building Code Standards & Certifications EPS Expandable Polystyrene Beads comply with building codes, ASTM standards, and international construction guidelines ensuring safe use in building insulation and structural applications.

Packaging Standards & Safety Adherence to FDA food contact regulations, packaging standards, and international safety guidelines supports responsible use in food packaging and consumer applications.

Environmental Standards & Recycling Compliance with environmental regulations, recycling standards, and sustainability guidelines ensures appropriate use in recyclable applications and environmental stewardship.

Performance Advantages & Technical Benefits

✔ Superior Thermal Insulation – Outstanding thermal resistance with low conductivity values

✔ Lightweight Properties – Exceptional strength-to-weight ratio for structural efficiency

✔ High Expansion Ratio – Up to 50:1 expansion for material efficiency

✔ Excellent Shock Absorption – Outstanding impact protection for packaging applications

✔ Moisture Resistance – Low water absorption for long-term performance

✔ Dimensional Stability – Excellent shape retention and manufacturing consistency

✔ Processing Versatility – Suitable for multiple molding and forming methods

✔ Flame Resistance – Self-extinguishing properties for safety applications

✔ Chemical Resistance – Resistance to acids, alkalis, and environmental chemicals

✔ Recyclability – 100% recyclable for sustainable applications

✔ Cost-Effective Solution – Economical alternative to other insulation materials

✔ Long-Term Performance – Maintains properties throughout service life

Our EPS Expandable Polystyrene Beads products represent industry-leading standards in expandable foam technology and multi-industry insulation solutions, specifically formulated for demanding construction operations, packaging applications, insulation systems, and specialized industrial applications. We provide comprehensive technical support, processing guidance, and application consultation to ensure optimal performance across your specialized construction, packaging, insulation, or industrial applications.

For detailed specifications, technical data sheets, or application-specific recommendations, contact our specialized foam materials division. We offer complete support including processing optimization, equipment recommendations, and technical guidance to maximize effectiveness in your construction, packaging, insulation, or industrial applications.

For more information about our products, feel free to Contact Us today.

Reviews

There are no reviews yet.