Copper pyrophosphate

Copper Pyrophosphate

High-Quality Copper Pyrophosphate (Cu2P2O7) – Premium Grade Chemical Compound for Electronics Manufacturing, Ceramic Production, Catalysts & Specialized Industrial Applications

Copper Pyrophosphate is a versatile inorganic compound extensively utilized in electronics manufacturing, ceramic production systems, catalyst preparation, and specialized industrial applications.

✅ High Purity Copper Content – Superior Chemical Properties & Processing Performance

✅ Consistent Quality Standards – Reliable Chemical Composition & Industrial Performance

✅ Electronics Grade Specifications – Manufacturing, Ceramics & Catalyst Applications

✅ Chemical Synthesis Compatible – Efficient Processing & Reaction Performance

✅ Electronics, Ceramics, Chemical Processing & Industrial Manufacturing Applications

High-Quality Copper Pyrophosphate for Electronics Manufacturing & Advanced Industrial Applications

Copper Pyrophosphate represents advanced inorganic chemistry technology specifically formulated for electronics manufacturing systems, ceramic production operations, catalyst preparation, and industrial applications requiring precise copper content and exceptional chemical purity. This essential chemical compound serves critical functions across electronic component production procedures, ceramic manufacturing processes, catalytic systems, and chemical synthesis operations requiring controlled copper composition, thermal stability, and industrial processing compatibility with exceptional quality consistency.

At Chemicals & Process Equipment Limited, we supply high-grade Copper Pyrophosphate manufactured under stringent quality control standards and international chemical specifications. Our comprehensive product range includes electronics grade copper pyrophosphate, ceramic grade compounds, and specialty formulations meeting diverse requirements for electronic manufacturing, ceramic production, catalyst preparation, and specialized industrial applications across global electronics, ceramics, and chemical manufacturing markets.

✅ Advanced Inorganic Chemistry Technology – Optimized Copper Content & Chemical Performance

✅ Consistent Quality Standards – Multiple Grade Classifications with Comprehensive Documentation

✅ Essential Chemical Properties – Superior Purity, Thermal Stability & Processing Performance

✅ Multi-Industrial Applications – Electronics, Ceramics, Catalysts & Chemical Manufacturing Industries

✅ Technical Support Package – Complete Processing Guidance & Industrial Optimization

The Global Copper Compounds Market is expected to grow from USD 2.8 Billion in 2024 to USD 3.9 Billion by 2031, at a CAGR of 4.9% during the forecast period, while the electronics chemicals market achieved a valuation of USD 58.4 billion in 2024 and is forecasted to climb to USD 89.2 billion by 2033, advancing at a CAGR of 4.8% from 2026 to 2033. This growth is driven by increasing electronics production demand, expanding ceramic applications, growing catalyst requirements, and rising specialty chemical adoption across global industrial markets.

Technical Specifications & Copper Pyrophosphate Properties

| Property | Electronics Grade | Ceramic Grade | Catalyst Grade | Premium Grade |

|---|---|---|---|---|

| Copper Content (Cu) | 38.5-39.5% | 37.0-40.0% | 38.0-40.0% | 39.0-39.8% |

| Phosphorus Content (P) | 11.8-12.2% | 11.0-13.0% | 11.5-12.5% | 11.9-12.1% |

| Purity (Cu2P2O7) | ≥99.5% | ≥98.0% | ≥99.0% | ≥99.8% |

| Iron (Fe) | ≤50 ppm | ≤200 ppm | ≤100 ppm | ≤20 ppm |

| Lead (Pb) | ≤20 ppm | ≤100 ppm | ≤50 ppm | ≤10 ppm |

| Zinc (Zn) | ≤30 ppm | ≤150 ppm | ≤80 ppm | ≤15 ppm |

| Nickel (Ni) | ≤25 ppm | ≤100 ppm | ≤60 ppm | ≤10 ppm |

| Cadmium (Cd) | ≤5 ppm | ≤20 ppm | ≤10 ppm | ≤2 ppm |

| Chloride (Cl) | ≤100 ppm | ≤500 ppm | ≤300 ppm | ≤50 ppm |

| Sulfate (SO4) | ≤200 ppm | ≤800 ppm | ≤500 ppm | ≤100 ppm |

| Moisture Content | ≤0.5% | ≤1.0% | ≤0.8% | ≤0.3% |

| Loss on Ignition | ≤1.0% | ≤2.0% | ≤1.5% | ≤0.8% |

| Particle Size (-325 mesh) | ≥95% | ≥85% | ≥90% | ≥98% |

| Bulk Density | 2.4-2.8 g/cm³ | 2.2-2.6 g/cm³ | 2.3-2.7 g/cm³ | 2.5-2.9 g/cm³ |

| Appearance | Blue-green fine powder | |||

| Crystal Structure | Monoclinic | Monoclinic | Monoclinic | Monoclinic |

| Melting Point | ~1000°C | ~1000°C | ~1000°C | ~1000°C |

| Decomposition Temp | >800°C | >800°C | >800°C | >800°C |

| pH (5% suspension) | 6.5-8.0 | 6.0-8.5 | 6.2-8.2 | 7.0-8.0 |

| Solubility in Water | Insoluble | Insoluble | Insoluble | Insoluble |

| Solubility in Acid | Soluble | Soluble | Soluble | Soluble |

| Thermal Stability | Excellent | Good | Very Good | Excellent |

| Chemical Stability | Stable | Stable | Stable | Very Stable |

| Surface Area (BET) | 5-15 m²/g | 3-12 m²/g | 4-14 m²/g | 8-18 m²/g |

| Electrical Conductivity | Low | Low | Low | Very Low |

| Storage Stability | 36 months | 24 months | 30 months | 48 months |

| Storage Conditions | Dry, cool, ventilated | Climate controlled | ||

| Packaging Options | 25kg drums, 500kg containers, 1000kg bulk |

Available Grade Types:

- Electronics grade copper pyrophosphate for semiconductor and electronic applications

- Ceramic grade compound for pottery, tiles, and ceramic manufacturing

- Catalyst grade copper pyrophosphate for chemical synthesis and catalytic processes

- Premium grade material for specialized high-performance applications

- Custom formulations for specific industrial requirements and processing conditions

Specialized Packaging Solutions:

- 25kg fiber drums with moisture-proof inner liners

- 500kg intermediate bulk containers for industrial operations

- 1000kg bulk containers for large-scale manufacturing processes

- Anti-static packaging for electronics industry applications

- Contamination-free packaging for high-purity requirements

- Vacuum-sealed packaging for extended storage stability

- Custom packaging for specific transport and handling requirements

Electronics Manufacturing Applications

Semiconductor Production Electronics manufacturers utilize copper pyrophosphate for semiconductor wafer processing, electronic component fabrication, and microelectronics systems requiring precise copper deposition and electrical properties. Chip manufacturers employ copper compounds for integrated circuit production and advanced electronics.

Printed Circuit Board Manufacturing PCB manufacturers use copper pyrophosphate for circuit board production, conductive trace formation, and electronic assembly requiring copper conductivity and processing reliability. Electronics assemblers employ copper compounds for PCB fabrication and electronic device manufacturing.

Electronic Component Production Electronic component manufacturers utilize copper pyrophosphate for capacitor production, resistor manufacturing, and component systems requiring controlled copper content and electrical performance. Specialty electronics producers employ copper compounds for precision components and electronic parts.

Display Technology Applications Display manufacturers use copper pyrophosphate for LCD production, OLED manufacturing, and display systems requiring copper electrodes and transparent conductive layers. Advanced display technology companies employ copper compounds for next-generation display applications.

Ceramic Production Applications

Technical Ceramics Manufacturing Ceramic manufacturers utilize copper pyrophosphate for advanced ceramics, structural ceramics, and technical applications requiring copper-enhanced properties and thermal performance. Industrial ceramics producers employ copper compounds for high-performance ceramic systems.

Electronic Ceramics Production Electronic ceramics manufacturers use copper pyrophosphate for capacitor ceramics, piezoelectric materials, and electronic ceramic systems requiring controlled electrical properties and copper functionality. Specialty ceramics producers employ copper compounds for electronic component applications.

Decorative Ceramics Applications Pottery and decorative ceramics manufacturers utilize copper pyrophosphate for glazes, ceramic pigments, and artistic applications requiring copper coloration and aesthetic properties. Art ceramics producers employ copper compounds for creative and decorative ceramic works.

Refractory Materials Production Refractory manufacturers use copper pyrophosphate for high-temperature ceramics, furnace linings, and thermal systems requiring copper-enhanced thermal properties and structural stability. Industrial refractory producers employ copper compounds for extreme temperature applications.

Catalyst Applications

Chemical Synthesis Catalysts Chemical manufacturers utilize copper pyrophosphate for organic synthesis, catalytic reactions, and chemical processing requiring copper catalytic activity and reaction efficiency. Specialty chemical producers employ copper compounds for advanced catalytic systems.

Hydrogenation Processes Hydrogenation facilities use copper pyrophosphate for catalyst preparation, hydrogen reactions, and chemical reduction requiring copper catalytic properties and process optimization. Chemical processing plants employ copper compounds for hydrogenation applications.

Oxidation Catalysts Oxidation process manufacturers utilize copper pyrophosphate for oxidation catalysts, air pollution control, and environmental systems requiring copper oxidation activity and emission control. Environmental technology companies employ copper compounds for catalytic oxidation.

Polymerization Catalysts Polymer manufacturers use copper pyrophosphate for polymerization catalysts, plastic production, and polymer systems requiring controlled molecular weight and polymer properties. Advanced polymer producers employ copper compounds for specialty polymerization processes.

Chemical Processing Applications

Copper Salt Production Chemical manufacturers utilize copper pyrophosphate for copper sulfate production, copper compounds manufacturing, and copper chemistry requiring copper source materials and chemical conversion. Specialty chemical producers employ copper compounds for copper salt synthesis.

Analytical Chemistry Applications Laboratory and analytical facilities use copper pyrophosphate for analytical standards, reference materials, and testing applications requiring precise copper content and analytical accuracy. Quality control laboratories employ copper compounds for chemical analysis.

Research & Development Applications Research institutions utilize copper pyrophosphate for materials research, chemical studies, and development applications requiring high-purity copper compounds and experimental protocols. University and industrial research facilities employ copper compounds for scientific investigation.

Specialty Chemical Production Specialty chemical manufacturers use copper pyrophosphate for custom formulations, niche applications, and specialized products requiring unique copper properties and performance characteristics. Advanced chemical producers employ copper compounds for innovative applications.

Industrial Manufacturing Applications

Metal Treatment Processes Metal treatment facilities utilize copper pyrophosphate for surface treatment, metal finishing, and coating applications requiring copper deposition and surface modification. Metal processing companies employ copper compounds for industrial metal treatment.

Pigment & Dye Production Pigment manufacturers use copper pyrophosphate for copper-based pigments, colorants, and dye applications requiring copper coloration and color stability. Specialty color producers employ copper compounds for advanced pigment systems.

Agricultural Chemical Production Agricultural chemical manufacturers utilize copper pyrophosphate for fungicide production, plant nutrition, and crop protection requiring copper antimicrobial properties and agricultural effectiveness. Agrochemical producers employ copper compounds for plant health applications.

Glass Manufacturing Applications Glass manufacturers use copper pyrophosphate for specialty glass, optical glass, and glass coloration requiring copper-enhanced properties and optical characteristics. Advanced glass producers employ copper compounds for technical glass applications.

Quality Control & Testing Procedures

Comprehensive Quality Assurance Every production batch undergoes extensive testing to ensure compliance with chemical standards, industrial specifications, and international quality requirements. Our quality control laboratory employs advanced analytical techniques including copper content analysis, purity determination, and chemical composition verification. For comprehensive information about copper compounds properties, applications, and research findings, visit RSC’s Copper Chemistry Database which provides detailed research data about copper effects on industrial processes, chemical applications, and materials science.

Quality assurance procedures include:

- Copper content determination using atomic absorption spectroscopy

- Phosphorus analysis using ICP-OES and colorimetric methods

- Purity assessment using X-ray diffraction and chemical analysis

- Heavy metals screening using ICP-MS and XRF techniques

- Moisture content determination using thermogravimetric analysis

- Particle size distribution analysis using laser diffraction methods

- Crystal structure verification using X-ray crystallography

- Thermal properties testing using differential scanning calorimetry

- Chemical stability evaluation under various environmental conditions

- Contamination screening using advanced analytical techniques

- Processing performance validation using standardized test methods

- Quality documentation and batch traceability systems

Application Guidelines & Best Practices

Processing Parameters & Optimization Establish optimal processing conditions for copper pyrophosphate including temperature control, reaction parameters, and system optimization for maximum copper utilization efficiency and processing performance.

Handling & Safety Procedures Implement appropriate safety protocols including personal protective equipment, ventilation systems, and emergency procedures for safe copper compound handling and processing operations.

Storage & Preservation Methods Develop proper storage techniques including moisture protection, contamination prevention, and quality maintenance for preserving copper pyrophosphate properties throughout storage periods.

System Integration Guidelines Ensure proper equipment compatibility, process integration, and operational optimization for effective copper pyrophosphate utilization in industrial processing systems.

Market Applications & Industry Trends

Electronics Industry Growth Expanding electronics manufacturing and semiconductor production drive continued growth in copper pyrophosphate applications for electronic components, PCB manufacturing, and advanced electronics across global technology markets.

Ceramic Industry Expansion Growing technical ceramics and advanced materials demand support increased adoption of copper pyrophosphate for ceramic manufacturing, electronic ceramics, and specialized ceramic applications.

Catalyst Technology Development Rising catalyst technology and environmental regulations drive growth in copper pyrophosphate applications for catalytic processes, emission control, and sustainable chemical manufacturing.

Specialty Chemical Innovation Increasing specialty chemical development and custom formulations support continued adoption of copper pyrophosphate for niche applications and high-performance chemical systems.

Environmental & Regulatory Compliance

Chemical Safety Standards Copper Pyrophosphate complies with chemical safety regulations, industrial hygiene standards, and workplace safety guidelines ensuring appropriate handling and use in industrial applications.

Environmental Protection Standards Compliance with environmental protection regulations, waste management standards, and pollution prevention guidelines supports responsible use and environmental stewardship in industrial operations.

Quality Control Regulations Adherence to quality control standards, chemical specifications, and international quality requirements ensures consistent performance and regulatory compliance across global markets.

Transportation Safety Standards Compliance with hazardous material transportation regulations, packaging requirements, and shipping safety guidelines ensures safe transport and delivery of copper pyrophosphate products.

Performance Advantages & Technical Benefits

✔ High Purity Content – Superior copper content and chemical performance

✔ Consistent Quality – Reliable chemical composition and processing properties

✔ Excellent Stability – Thermal and chemical stability under processing conditions

✔ Versatile Applications – Multiple industrial and manufacturing applications

✔ Cost-Effective Processing – Efficient copper utilization and resource optimization

✔ Environmental Benefits – Sustainable processing and waste reduction

✔ Quality Assurance – Comprehensive testing and quality control systems

✔ Technical Support – Expert guidance and application assistance

✔ Global Availability – Reliable supply chain and distribution network

✔ Custom Solutions – Tailored products for specific industrial requirements

✔ Storage Stability – Extended shelf life under proper storage conditions

✔ Safety Compliance – Meeting industrial safety and regulatory standards

Our Copper Pyrophosphate products represent industry-leading standards in inorganic chemistry technology and industrial chemical solutions, specifically formulated for demanding electronics manufacturing, ceramic production, catalyst preparation, and specialized industrial applications. We provide comprehensive technical support, processing guidance, and application consultation to ensure optimal performance across your specialized chemical processing, electronics manufacturing, or industrial production applications.

For detailed specifications, certificates of analysis, or application-specific recommendations, contact our specialized chemical products division. We offer complete support including processing optimization, handling protocol development, and technical guidance to maximize effectiveness in your electronics manufacturing, ceramic production, or chemical processing applications.

For more information about our products, feel free to Contact Us today.

Related products

Zinc/Ash/Dust Powder

Zinc/Ash/Dust Powder

High-Quality Zinc/Ash/Dust Powder – Premium Grade Industrial Raw Material for Metallurgy, Chemical Processing, Fertilizer Production & Zinc Recovery Applications

Zinc/Ash/Dust Powder is a versatile industrial raw material extensively utilized in metallurgical operations, chemical processing systems, fertilizer manufacturing, and zinc recovery applications.

✅ High Zinc Content – Superior Metal Recovery & Processing Properties

✅ Consistent Quality Standards – Reliable Chemical Composition & Performance

✅ Industrial Grade Specifications – Metallurgy, Chemical & Fertilizer Applications

✅ Zinc Recovery Compatible – Efficient Metal Extraction & Purification Processes

✅ Metallurgical, Chemical Processing, Fertilizer & Industrial Manufacturing Applications

High Carbon Graphite Powder

High Carbon Graphite Powder 95-99%

Premium Quality High Carbon Graphite Powder – Industrial Grade Carbon Material for Steel Manufacturing, Lithium Battery Production, Foundry Applications & Advanced Lubricant Systems

High Carbon Graphite Powder 95-99% is a versatile industrial-grade carbon material extensively utilized in steel manufacturing, lithium battery production, foundry operations, and advanced lubrication applications.

✅ High Carbon Content – Superior Purity & Industrial Performance Standards

✅ 95-99% Carbon Purity – Exceptional Quality & Conductivity Specifications

✅ Multi-Industry Applications – Steel, Battery, Foundry & Lubricant Manufacturing

✅ Excellent Thermal Stability – High Temperature Resistance & Processing Reliability

✅ Metallurgical, Battery Production, Foundry & Industrial Lubrication Applications

Pure Lead Powder

Pure Lead Powder

High-Quality Pure Lead Powder – Premium Grade Metal Powder for Industrial Applications, Battery Manufacturing, Radiation Shielding & Specialized Production

Pure Lead Powder is a versatile metal powder extensively utilized in industrial applications, battery manufacturing operations, radiation shielding systems, and specialized production processes.

✅ High-Purity Metal Powder – Superior Quality & Processing Performance

✅ Multiple Application Methods – Battery Manufacturing, Radiation Shielding, Industrial & Specialty Uses

✅ Excellent Physical Properties – Superior Density, Malleability & Corrosion Resistance

✅ Industry Compliance – Meeting International Safety & Environmental Standards

✅ Industrial Manufacturing, Battery Production, Radiation Protection & Specialized Applications

Recently Viewed

Thiourea Dioxide

THIOUREA DIOXIDE

Premium Quality Thiourea Dioxide – Ultra-Pure Reducing Agent, Advanced Textile Processing Chemical & Superior Bleaching Activator for Textile Manufacturing, Paper Processing, Dye Applications, Polymer Industries & Chemical Synthesis with Enhanced Environmental Safety

✅ Powerful Reducing Agent – Superior Reduction Capability Without Hydrogen Sulfide Gas Generation

✅ Environmental Safety – Green Alternative to Traditional Reducing Agents with No Toxic Emissions

✅ Excellent Thermal Stability – Maintains Performance Under Processing Temperature Conditions

✅ Multi-Industry Applications – Enhanced Textile Processing, Paper Manufacturing & Chemical Synthesis

✅ Quality Assured – Industrial & Technical Grade Standards Supporting Optimal Performance Results

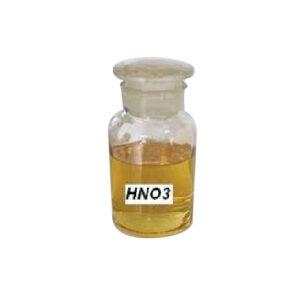

NITRIC ACID

Nitric Acid (HNO₃)

Industrial Grade Nitric Acid 68-70% – Premium Chemical Oxidizing Agent

Nitric acid (HNO₃) is a highly versatile and powerful oxidizing agent extensively utilized in fertilizer manufacturing, metal processing, electronics industry, chemical synthesis, and industrial cleaning applications. Our industrial-grade nitric acid delivers exceptional oxidizing performance with consistent concentration and high purity for demanding chemical processing applications.

✅ 68-70% Industrial Grade Concentration – Superior Oxidizing Performance

✅ Clear Colorless Liquid – Highly Corrosive & Reactive Properties

✅ Technical, ACS & Electronic Grades Available

✅ CAS 7697-37-2 Certified – Laboratory & Industrial Standards

✅ Used in Fertilizer Production, Metal Treatment, Electronics, Chemical Manufacturing

Dicopper pyrophosphate

DICOPPER PYROPHOSPHATE – Advanced Industrial & Chemical Solution

Professional Dicopper Pyrophosphate – High-Performance Electroplating Agent, Catalyst Component, Pigment Precursor, Flame Retardant, Ceramic Additive, Analytical Reagent, Copper Source & Specialized Chemical for Industrial Applications, Electronics Manufacturing, Ceramics, Pharmaceuticals & Advanced Chemical Processing Technology

✅ Premium Electroplating Agent – Superior Copper Deposition & Electronics Processing Excellence

✅ Catalyst Excellence – Outstanding Chemical Reaction Enhancement & Industrial Applications

✅ Pigment Quality – Exceptional Color Development & Coating Technology Compatibility

✅ Electronics Proven – Superior Circuit Board Manufacturing & Copper Plating Applications

✅ Quality Assured – Industrial, Electronics, Pharmaceutical & Global Standards Compliance Worldwide

SODIUM CYANIDE

Sodium Cyanide

Sodium Cyanide 98% Purity – Technical & Mining Grade

Sodium Cyanide is a highly effective chemical compound primarily used in gold mining extraction, electroplating, and chemical synthesis. Our technical-grade sodium cyanide ensures optimal performance in cyanidation processes and metal recovery operations with strict quality control.

✅ 98% Minimum Purity – Superior Technical Grade Quality

✅ White Crystalline Solid – High Solubility Properties

✅ Mining & Electroplating Grade Available

✅ Secure Packaging with Safety Documentation

✅ Used in Gold Extraction, Silver Recovery, Electroplating, and Chemical Manufacturing

Sodium Polyacrylate

Sodium Polyacrylate SAP

Premium Quality Sodium Polyacrylate – Technical/Medical Grade Super Absorbent Polymer for Disposable Diapers, Adult Incontinence Products, Agriculture & Water Treatment Applications

Sodium Polyacrylate SAP (Super Absorbent Polymer) is a versatile ultra-high absorbency synthetic polymer extensively utilized in disposable diaper manufacturing, adult incontinence products, agricultural water retention, and specialized absorption applications.

✅ Ultra-High Absorbency Polymer – Superior Water Absorption & Multi-Industry Performance

✅ Multiple Absorption Capacities – 300-800 g/g for Specialized Applications

✅ Excellent Retention Properties – Technical/Medical Grade for Optimal Performance

✅ Multi-Industry Compatible – Enhanced Hygiene, Agricultural & Industrial Properties

✅ Disposable Diapers, Adult Incontinence, Agriculture & Water Treatment Applications

Sodium Thiosulfate

SODIUM THIOSULFATE Na2S2O3 – Advanced Dechlorination & Industrial Solution

Professional Anhydrous & Pentahydrate Sodium Thiosulfate Na2S2O3 – High-Performance Inorganic Salt, Dechlorination Agent, Photography Chemical, Water Treatment Neutralizer, Medical Antidote, Analytical Reagent, Textile Processing Aid, Paper Manufacturing Chemical, Gold Mining Leachant & Specialized Thiosulfate Compound for Water Treatment, Photography Industry, Medical Applications, Mining Operations & Advanced Chemical Processing Technology

✅ Premium Pharmaceutical Grade – Superior Purity & Medical Applications Excellence

✅ Photography Quality – Outstanding Performance & Film Development Applications

✅ Water Treatment Proven – Exceptional Dechlorination & Neutralization Compatibility

✅ Mining Compatible – Superior Gold Recovery Properties & Extraction Applications

✅ Quality Assured – High Activity, Low Contaminants & Global Standards Compliance Worldwide

MAGNESIUM NITRATE

Magnesium Nitrate Hexahydrate

Premium Quality Magnesium Nitrate – Technical Grade for Agricultural Applications, Concrete Enhancement, Water Treatment & Specialized Chemical Processing Systems

Magnesium Nitrate Hexahydrate is a highly soluble crystalline compound extensively utilized in agricultural fertilization, concrete enhancement, water treatment, and specialized chemical processing applications.

✅ High-Purity Magnesium Nitrate Hexahydrate – Superior Quality & Multi-Industry Performance

✅ Multiple Purity Grades – 98%, 99%, 99.5% for Specialized Applications

✅ Excellent Solubility Properties – Technical Grade for Optimal Performance Standards

✅ Dual Nutrient Source – Enhanced Plant Nutrition with Nitrogen & Magnesium

✅ Agricultural, Construction, Water Treatment & Chemical Applications

Sodium Bromide

SODIUM BROMIDE – Advanced Oil Field & Industrial Chemical Solution

Professional Sodium Bromide – High-Performance Clear Brine Fluid, Oil Drilling Chemical, Completion Fluid, Workover Fluid, Pharmaceutical Intermediate & Specialized Chemical Solution for Oil & Gas Operations, Industrial Processing, Medical Applications, Water Treatment, Photography & Advanced Chemical Manufacturing

✅ Premium Clear Brine – Superior Density Control & Oil Field Performance

✅ Industrial Excellence – Outstanding Chemical Purity & Processing Compatibility

✅ Oil Field Proven – Exceptional Completion Fluid & Workover Applications

✅ Medical Applications – Pharmaceutical Grade & Healthcare Compatibility

✅ Quality Assured – Oil Field, Industrial & Medical Standards Compliance Globally

GLUCOSE LIQUID

Glucose Liquid

Food Grade & Pharmaceutical Grade Liquid Glucose – Multi-Purpose Industrial Sweetening Agent & Excipient for Food Manufacturing, Pharmaceutical Formulations & Industrial Processing Applications

Glucose Liquid is a versatile industrial sweetener extensively utilized in food manufacturing, pharmaceutical formulations, confectionery production, and specialized industrial applications. Our technical-grade liquid glucose delivers exceptional sweetening performance and functional properties with superior purity for demanding food processing, pharmaceutical manufacturing, and industrial applications requiring safe, effective glucose-based ingredients.

✅ High-Performance Industrial Sweetener – Superior Functionality & Processing Performance

✅ Multiple Grade Formulations – Food Grade, Pharmaceutical Grade & Industrial Specifications

✅ Various Dextrose Equivalent Options – Customized Sweetening & Functional Properties

✅ Safe for Food & Pharmaceutical Applications – Non-Crystallizing & Stable Properties

✅ Food Manufacturing, Pharmaceutical, Confectionery & Industrial Applications

CALCIUM NITRATE

Calcium Nitrate

Premium Quality Calcium Nitrate – Technical Grade for Agricultural Applications, Industrial Manufacturing, Concrete Acceleration & Specialized Chemical Processing Systems

Calcium Nitrate Tetrahydrate is a highly soluble crystalline compound extensively utilized in agricultural fertilization, industrial manufacturing, concrete acceleration, and specialized chemical processing applications.

✅ Ultra-High Purity Calcium Nitrate – Superior Quality & Multi-Industry Performance

✅ Multiple Purity Grades – 99%, 99.5%, 99.7% for Specialized Applications

✅ Excellent Solubility Properties – Technical Grade for Optimal Performance Standards

✅ Multi-Industry Compatible – Enhanced Plant Nutrition, Concrete Acceleration & Processing Properties

✅ Agricultural, Industrial, Construction, Chemical & Horticultural Applications

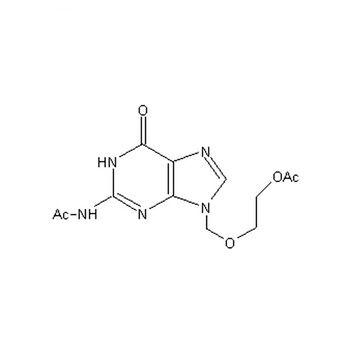

Diacetyl Acyclovir

Diacetyl Acyclovir (Diacetylacyclovir)

Premium Quality Diacetyl Acyclovir (Diacetylacyclovir) – High-Purity Pharmaceutical Intermediate & Antiviral Drug Precursor for Acyclovir Manufacturing, Antiviral Drug Synthesis, API Production, Pharmaceutical Manufacturing & Research Applications

✅ Premium Pharmaceutical Intermediate – Superior Purity & Synthetic Properties

✅ Multiple Purity Grades – Various Quality Levels for Specific Pharmaceutical Applications

✅ Excellent Stability Properties – Superior Storage Stability, Controlled Composition, Precise Processing

✅ Multi-Application Compatible – Enhanced Pharmaceutical, Research, Manufacturing & Development Applications

✅ Quality Assured – Established Pharmaceutical Guidelines Supporting Optimal Performance

MAGNESIUM SULPHATE

Magnesium Sulphate Heptahydrate (MgSO4·7H2O)

Premium Quality Magnesium Sulphate – High-Grade Epsom Salt for Agricultural Applications, Healthcare Industry, Industrial Processing & Horticultural Systems

Magnesium Sulphate Heptahydrate is a versatile magnesium-sulfur compound extensively utilized in agricultural operations, healthcare applications, industrial processing systems, and horticultural programs.

✅ High-Purity Magnesium-Sulfur Compound – Superior Nutrient Availability & Multi-Industry Performance

✅ Multiple Application Methods – Foliar Feeding, Soil Application, Injectable Solutions & Industrial Processing

✅ Excellent Nutrient Properties – 10% Magnesium, 13% Sulfur for Optimal Plant & Industrial Applications

✅ Multi-Industry Compatible – Enhanced Chlorophyll Production, Medical Applications & Industrial Processing

✅ Agricultural, Healthcare, Industrial, Horticultural & Personal Care Applications

Reviews

There are no reviews yet.