CALCIUM CHLORIDE

CALCIUM CHLORIDE

Premium Quality Calcium Chloride – High-Purity Hygroscopic Agent, Advanced De-icing Chemical & Superior Performance Moisture Control Agent for Industrial Applications, Road Maintenance Operations, Oil & Gas Drilling, Food Processing & Water Treatment Applications

✅ Premium Hygroscopic Agent – Superior Moisture Absorption & High Chemical Performance

✅ Multiple Form Options – Anhydrous, Dihydrate, Liquid & Pellet Forms Available

✅ Excellent Processing Properties – Fast Dissolution, Superior De-icing Performance

✅ Multi-Industry Compatible – Road Maintenance, Oil & Gas, Food & Industrial Applications

✅ Quality Assured – Established Performance Standards Supporting Optimal Processing Results

High-Quality Calcium Chloride

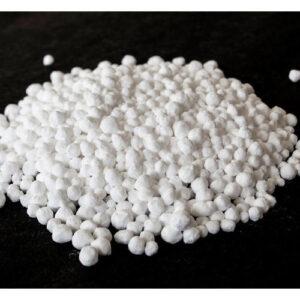

Calcium Chloride, with chemical formula CaCl₂ and CAS number 10043-52-4, commonly known as Calcium Dichloride, Calcic Chloride, or Lime Chloride, available in various forms including anhydrous powder (94-97% CaCl₂), dihydrate crystals (99-103% CaCl₂·2H₂O), liquid brine (30-40% CaCl₂), pellets/prills (90-95% CaCl₂), hexahydrate crystals (98-102% CaCl₂·6H₂O), and flakes (92-96% CaCl₂), is a white hygroscopic solid with exceptional moisture absorption properties and outstanding solubility characteristics appearing as white crystalline solid with excellent dissolution rate and superior performance control. Calcium Chloride is specifically manufactured to provide reliable moisture absorption, effective freezing point depression, superior dust suppression, and controlled performance characteristics, making it ideal for applications requiring de-icing operations, dust control, concrete acceleration, oil field drilling, and food processing in road maintenance operations, industrial processing facilities, oil & gas drilling sites, concrete manufacturing plants, and food processing facilities. The compound works through several mechanisms including hygroscopic moisture absorption for humidity control, ionic dissociation for freezing point depression, calcium ion release for concrete acceleration, and osmotic pressure for dust suppression, providing superior hygroscopic performance, reliable processing characteristics, effective environmental control, and outstanding quality consistency. Calcium Chloride represents one of the most versatile industrial chemicals across multiple industries, providing exceptional moisture control, superior de-icing effectiveness, excellent dust suppression, and outstanding processing reliability, making it essential for road maintenance crews, industrial processors, oil field operators, concrete manufacturers, and food processors requiring high-performance hygroscopic chemicals and comprehensive technical support.

At Chemicals & Process Equipment Limited, we supply high-performance Calcium Chloride manufactured under stringent quality control standards and international road maintenance, industrial, oil field, food processing, and pharmaceutical application specifications. Our comprehensive product range includes various concentrations, particle sizes, and specialized forms meeting diverse requirements for de-icing operations, dust control, industrial processing, oil field applications, and food processing across global infrastructure, industrial, energy, and food markets.

✅ Advanced Hygroscopic Technology – Optimized Moisture Control & Multi-Industry Applications

✅ Consistent Quality Standards – Multiple Product Classifications with Comprehensive Documentation

✅ Essential Industrial Chemical – Superior Functional, Processing & Performance Characteristics

✅ Multi-Industry Applications – Road Maintenance, Oil & Gas, Food Processing, Industrial Operations

✅ Technical Support Package – Complete Application Guidance & Performance Optimization

The global calcium chloride market was valued at approximately USD 1.89 billion in 2023 and is projected to reach USD 2.65 billion by 2030, growing at a CAGR of 4.9% during the forecast period. Market expansion is driven by increasing winter road maintenance, growing oil & gas drilling activities, expanding concrete production, and rising industrial processing applications.

Technical Specifications & Calcium Chloride Properties

| Property | Anhydrous Powder | Dihydrate Crystals | Liquid Brine | Pellets/Prills | Hexahydrate | Flakes |

|---|---|---|---|---|---|---|

| CaCl₂ Content (%) | 94.0-97.0 | 99.0-103.0* | 30.0-40.0 | 90.0-95.0 | 98.0-102.0** | 92.0-96.0 |

| Calcium (Ca) Content (%) | 34.7-35.8 | 27.2-28.3 | 8.3-11.1 | 33.2-35.1 | 18.3-19.1 | 34.0-35.4 |

| Water Content (%) | 1.0-3.0 | N/A | 60.0-70.0 | 2.0-5.0 | N/A | 2.0-4.0 |

| Magnesium (Mg) (%) | 0.1-0.5 | 0.05-0.3 | 0.02-0.2 | 0.08-0.4 | 0.04-0.25 | 0.1-0.4 |

| Sodium (Na) (%) | 0.5-2.0 | 0.2-1.0 | 0.1-0.8 | 0.3-1.5 | 0.15-0.8 | 0.4-1.8 |

| Potassium (K) (%) | 0.1-0.8 | 0.05-0.4 | 0.02-0.3 | 0.08-0.6 | 0.03-0.3 | 0.1-0.7 |

| Sulfate (SO₄) (%) | 0.05-0.2 | 0.02-0.1 | 0.01-0.08 | 0.03-0.15 | 0.015-0.08 | 0.04-0.18 |

| Hydroxide (OH) (%) | 0.02-0.1 | 0.01-0.05 | 0.005-0.03 | 0.015-0.08 | 0.008-0.04 | 0.02-0.09 |

| Iron (Fe) (ppm) | 5-20 | 2-10 | 1-5 | 3-15 | 1.5-8 | 4-18 |

| Heavy Metals (as Pb) (ppm) | 2-8 | 1-4 | 0.5-2 | 1.5-6 | 0.8-3 | 2-7 |

| Aluminum (Al) (ppm) | 5-15 | 2-8 | 1-4 | 3-12 | 1.5-6 | 4-14 |

| pH (10% solution) | 7.5-9.0 | 8.0-9.5 | 7.0-8.5 | 7.8-9.2 | 8.2-9.8 | 7.6-9.1 |

| Bulk Density (kg/m³) | 1000-1400 | 1200-1600 | 1250-1350 | 900-1300 | 800-1200 | 700-1100 |

| True Density (g/cm³) | 2.15 | 1.85 | 1.3-1.4 | 2.15 | 1.71 | 2.15 |

| Particle Size D50 (μm) | 100-500 | 200-1000 | N/A | 2000-6000 | 500-2000 | 1000-5000 |

| Particle Size D97 (μm) | 500-2000 | 1000-4000 | N/A | 8000-15000 | 2000-8000 | 5000-20000 |

| Water Solubility (g/L at 20°C) | 745 | 745 | Miscible | 745 | 745 | 745 |

| Dissolution Time (min) | 2-5 | 3-8 | Instant | 5-15 | 1-4 | 3-10 |

| Deliquescence RH (%) | 29.5 | 29.5 | N/A | 29.5 | 29.5 | 29.5 |

| Melting Point (°C) | 772 | 176* | N/A | 772 | 30** | 772 |

| Boiling Point (°C) | 1935 | N/A | 100+ | 1935 | N/A | 1935 |

| Specific Heat (J/g·K) | 0.68 | 1.2 | 3.2 | 0.68 | 1.8 | 0.68 |

| Heat of Solution (kJ/mol) | -81.3 | -46.2 | N/A | -81.3 | -15.3 | -81.3 |

| Thermal Conductivity (W/m·K) | 1.2 | 0.8 | 0.6 | 1.2 | 0.6 | 1.2 |

| Electrical Conductivity (mS/cm) | 420-480 | 380-440 | 250-350 | 400-460 | 320-380 | 410-470 |

| Hygroscopicity | Very High | Very High | N/A | Very High | Very High | Very High |

| Flowability | Good | Excellent | N/A | Excellent | Good | Fair |

| Caking Tendency | Moderate | Low | N/A | Low | Moderate | High |

| Angle of Repose (°) | 35-45 | 25-35 | N/A | 30-40 | 30-40 | 40-55 |

| Compressibility | Moderate | Low | N/A | Low | Moderate | High |

| Freezing Point Depression | Excellent | Excellent | Good | Excellent | Excellent | Excellent |

| Eutectic Temperature (°C) | -51.1 | -51.1 | -35 to -45 | -51.1 | -51.1 | -51.1 |

| Ice Melting Capacity | 27% at -18°C | 27% at -18°C | 18% at -18°C | 27% at -18°C | 27% at -18°C | 27% at -18°C |

| Dust Suppression Efficiency (%) | 75-85 | 70-80 | 85-95 | 80-90 | 70-80 | 70-80 |

| Concrete Acceleration (%) | 25-40 | 20-35 | 15-30 | 30-45 | 18-32 | 25-38 |

| Color | White | White | Clear/Colorless | White | White | White |

| Appearance | Fine Powder | Crystals | Liquid | Pellets/Prills | Large Crystals | Flakes |

| Odor | Odorless | Odorless | Odorless | Odorless | Odorless | Odorless |

| Taste | Bitter/Salty | Bitter/Salty | Bitter/Salty | Bitter/Salty | Bitter/Salty | Bitter/Salty |

| Toxicity | Low | Low | Low | Low | Low | Low |

| Skin Contact Effect | Irritating | Mild Irritation | Mild Irritation | Irritating | Mild Irritation | Irritating |

| Eye Contact Effect | Irritating | Irritating | Irritating | Irritating | Irritating | Irritating |

| Environmental Impact | Low | Low | Low | Low | Low | Low |

| Biodegradability | N/A | N/A | N/A | N/A | N/A | N/A |

| Storage Temperature (°C) | 10-40 | 10-35 | 5-40 | 10-40 | 5-30 | 10-40 |

| Storage Humidity (%) | <50 | <60 | N/A | <55 | <70 | <45 |

| Packaging | Bags/Drums | Bags/Boxes | Tanks/Containers | Bags/Bulk | Bags/Drums | Bags/Bulk |

| Shelf Life (months) | 60 | 48 | 24 | 54 | 36 | 48 |

| Container Material | PE/PP/Paper | PE/PP/Paper | PE/Steel/FRP | PE/PP/Paper | PE/PP/Paper | PE/PP/Paper |

| Transport Class | Non-Hazardous | Non-Hazardous | Non-Hazardous | Non-Hazardous | Non-Hazardous | Non-Hazardous |

| Regulatory Status | Industrial | Industrial | Industrial | Industrial | Industrial | Industrial |

| Food Grade Available | Yes | Yes | Yes | Yes | Limited | Yes |

| USP Compliance | Yes | Yes | Limited | Limited | Yes | Limited |

| Application Temperature (°C) | -40 to 80 | -30 to 70 | -20 to 60 | -40 to 80 | -10 to 50 | -35 to 75 |

| Spreading Rate (g/m²) | 20-50 | 25-60 | 100-300 | 15-40 | 30-70 | 25-55 |

| Effective Temperature (°C) | -51 to 0 | -51 to 0 | -45 to 0 | -51 to 0 | -51 to 0 | -51 to 0 |

| Working Time (hours) | 6-24 | 8-30 | 4-12 | 8-36 | 10-48 | 6-24 |

| Compatibility | Excellent | Excellent | Good | Excellent | Excellent | Good |

| Corrosivity | Moderate | Moderate | High | Moderate | Moderate | Moderate |

| Equipment Compatibility | Good | Good | Fair | Good | Good | Fair |

| Cost Effectiveness | High | Medium | Very High | Medium | Low | High |

| Performance Reliability | Excellent | Excellent | Good | Excellent | Good | Good |

| Technical Support | Enhanced | Standard | Enhanced | Standard | Limited | Standard |

| Application Training | Yes | Yes | Yes | Limited | Limited | Limited |

| Custom Formulation | Yes | Limited | Yes | Limited | No | Limited |

| Performance Testing | Available | Available | Required | Available | Limited | Available |

| Field Trials | Yes | Yes | Yes | Limited | No | Limited |

| Global Availability | Worldwide | Worldwide | Regional | Worldwide | Limited | Worldwide |

| Supply Reliability | Excellent | Excellent | Good | Excellent | Fair | Good |

| Lead Time (days) | 5-12 | 7-15 | 3-10 | 7-14 | 14-30 | 10-18 |

| Minimum Order (MT) | 1 | 5 | 20 | 10 | 1 | 5 |

| Bulk Pricing | Available | Available | Available | Available | Limited | Available |

| Contract Terms | Flexible | Flexible | Specialized | Standard | Premium | Flexible |

*As CaCl₂·2H₂O | **As CaCl₂·6H₂O

Available Product Types:

- Anhydrous Powder Calcium Chloride for industrial and de-icing applications

- Dihydrate Crystals Calcium Chloride for general purpose and concrete applications

- Liquid Brine Calcium Chloride for dust control and de-icing operations

- Pellets/Prills Calcium Chloride for road maintenance and bulk applications

- Hexahydrate Crystals Calcium Chloride for laboratory and pharmaceutical uses

- Flakes Calcium Chloride for specialized industrial applications

- Food Grade Calcium Chloride for food processing and beverage applications

- Oil Field Grade for drilling fluids and completion operations

- Technical Grade for general industrial and commercial applications

- USP Grade for pharmaceutical and medical applications

- De-icing Grade for winter road maintenance operations

- Dust Control Grade for unpaved road and construction site applications

Specialized Application Solutions:

- Winter road de-icing and snow melting systems

- Dust suppression and unpaved road maintenance

- Oil & gas drilling fluid formulation and completion operations

- Concrete acceleration and cold weather construction

- Food processing and cheese making applications

- Desiccant and moisture control systems

- Brine refrigeration and cooling applications

- Water treatment and swimming pool maintenance

- Industrial process heating and cooling systems

- Tire ballast and liquid weight applications

- Quality control systems and analytical testing protocols

- Application optimization and efficiency improvement consulting

- Technical training and best practices programs

- Environmental compliance and safety management services

Road Maintenance and De-icing Applications

Winter Road De-icing Operations Road maintenance departments utilize Calcium Chloride for ice melting, snow removal, and winter safety requiring de-icing grade specifications. Highway maintenance crews employ calcium chloride for pre-treatment, anti-icing applications requiring road safety, traffic flow, and weather protection in winter road maintenance operations.

Dust Control Applications Construction companies use Calcium Chloride for dust suppression, road stabilization, and air quality control requiring dust control grade specifications. Site managers employ calcium chloride for unpaved road treatment, construction site dust control applications requiring air quality, worker safety, and environmental compliance in construction operations.

Pre-wetting Applications Snow removal contractors utilize Calcium Chloride for pre-wetting salt, application enhancement, and performance optimization requiring liquid brine specifications. Winter service operators employ calcium chloride brine for improved spreading, reduced bounce applications requiring material efficiency, cost reduction, and enhanced performance in winter maintenance.

Parking Lot Maintenance Property managers use Calcium Chloride for parking area de-icing, pedestrian safety, and facility maintenance requiring commercial grade specifications. Facility maintenance teams employ calcium chloride for walkway treatment, entrance safety applications requiring slip prevention, liability reduction, and customer safety in commercial property maintenance.

For comprehensive information about calcium chloride de-icing applications, winter maintenance benefits, and application techniques, visit the Transportation Research Board Winter Maintenance Guidelines which provides detailed guidance on calcium chloride properties, de-icing applications, and best practices for transportation professionals.

Oil & Gas and Industrial Applications

Drilling Fluid Operations Oil field service companies utilize Calcium Chloride for drilling fluid formulation, wellbore stability, and density control requiring oil field grade specifications. Drilling engineers employ calcium chloride for completion fluids, workover operations applications requiring formation protection, wellbore integrity, and operational efficiency in oil & gas drilling.

Completion Fluid Applications Well completion specialists use Calcium Chloride for clear brine fluids, formation damage prevention, and reservoir protection requiring completion grade specifications. Completion engineers employ calcium chloride for packer fluids, displacement operations applications requiring formation compatibility, corrosion control, and well productivity in completion operations.

Industrial Process Cooling Industrial manufacturers utilize Calcium Chloride for refrigeration brines, process cooling, and heat transfer requiring industrial grade specifications. Process engineers employ calcium chloride for chilled water systems, cooling tower applications requiring heat transfer efficiency, freeze protection, and system reliability in industrial cooling.

Concrete Acceleration Concrete producers use Calcium Chloride for setting acceleration, cold weather construction, and strength development requiring concrete grade specifications. Construction professionals employ calcium chloride for winter concreting, rapid strength gain applications requiring early strength, demolding time reduction, and project scheduling in concrete construction.

Food Processing and Specialty Applications

Food Processing Operations Food manufacturers utilize Calcium Chloride for cheese making, food firming, and calcium fortification requiring food grade specifications. Food technologists employ calcium chloride for curd formation, texture improvement applications requiring food safety, nutritional enhancement, and product quality in food processing.

Beverage Production Beverage producers use Calcium Chloride for water treatment, mineral adjustment, and taste enhancement requiring beverage grade specifications. Beverage formulators employ calcium chloride for brewing water, bottled water applications requiring mineral balance, taste optimization, and product consistency in beverage manufacturing.

Pharmaceutical Applications Pharmaceutical companies utilize Calcium Chloride for drug formulation, injection solutions, and medical applications requiring USP grade specifications. Pharmaceutical specialists employ calcium chloride for electrolyte solutions, calcium supplementation applications requiring purity standards, safety compliance, and therapeutic effectiveness in pharmaceutical manufacturing.

Laboratory Applications Research facilities use Calcium Chloride for desiccant applications, chemical synthesis, and analytical procedures requiring laboratory grade specifications. Laboratory technicians employ calcium chloride for moisture control, drying agent applications requiring chemical purity, analytical accuracy, and research reliability in laboratory operations.

Water Treatment and Environmental Applications

Swimming Pool Treatment Pool service companies utilize Calcium Chloride for calcium hardness adjustment, water balance, and equipment protection requiring pool grade specifications. Pool maintenance professionals employ calcium chloride for hardness increase, plaster protection applications requiring water chemistry, equipment longevity, and swimmer comfort in pool maintenance.

Industrial Water Treatment Water treatment facilities use Calcium Chloride for hardness adjustment, pH control, and treatment enhancement requiring water treatment grade specifications. Water treatment operators employ calcium chloride for process water conditioning, cooling tower treatment applications requiring water quality, system protection, and operational efficiency in water treatment.

Waste Water Treatment Environmental companies utilize Calcium Chloride for flocculation aid, precipitation enhancement, and treatment optimization requiring environmental grade specifications. Environmental engineers employ calcium chloride for heavy metal removal, phosphorus precipitation applications requiring treatment efficiency, discharge compliance, and environmental protection in wastewater treatment.

Soil Stabilization Construction contractors use Calcium Chloride for soil modification, base stabilization, and dust control requiring stabilization grade specifications. Geotechnical engineers employ calcium chloride for unpaved road improvement, construction site stabilization applications requiring soil strength, dust suppression, and construction efficiency in earthwork operations.

Quality Control & Testing Procedures

Comprehensive Quality Assurance Every production batch undergoes extensive testing to ensure compliance with calcium chloride standards, road maintenance requirements, oil field specifications, food grade standards, and international quality standards. Our quality control laboratory employs advanced analytical techniques including chemical composition analysis, purity determination, and comprehensive performance evaluation.

Quality assurance procedures include:

- Calcium chloride content determination using gravimetric methods

- Calcium content analysis using complexometric titration

- Water content determination using Karl Fischer titration

- Magnesium content testing using atomic absorption spectroscopy

- Sodium content analysis using flame photometry

- Potassium content testing using atomic absorption spectroscopy

- Sulfate content determination using gravimetric methods

- Hydroxide content testing using acid-base titration

- Iron content analysis using atomic absorption spectroscopy

- Heavy metals testing using ICP-MS and atomic absorption

- Aluminum content determination using instrumental methods

- pH measurement using calibrated electrodes

- Particle size distribution analysis using sieve analysis

- Bulk density testing using standardized procedures

- Dissolution time measurement using dissolution apparatus

- Deliquescence point testing using humidity chambers

- Hygroscopicity testing using moisture absorption methods

- Freezing point depression testing using cryoscopic methods

- Ice melting capacity testing using standardized protocols

- Dust suppression efficiency testing using field methods

- Concrete acceleration testing using standard procedures

- Thermal analysis using TGA and DSC methods

- Crystal structure analysis using X-ray diffraction

- Scanning electron microscopy for morphology analysis

- Chemical purity testing using chromatographic methods

- Corrosivity testing using material compatibility studies

- Microbiological testing for food grade products

- Stability testing using accelerated aging protocols

- Packaging integrity testing using standard methods

- Performance testing using application-specific protocols

- Environmental compliance verification using standard methods

- Quality system compliance using ISO and food safety standards

- Customer application support using pilot testing

- Technical consultation using expert evaluation

- Continuous improvement using statistical process control

Storage & Handling Procedures Implement proper storage conditions including moisture protection, temperature control, contamination prevention, proper ventilation, and comprehensive handling procedures for maintaining Calcium Chloride quality and ensuring safe processing throughout storage and application periods while following all best practices for hygroscopic chemical handling.

Market Applications & Industry Trends

Winter Maintenance Market Growth Growing winter road maintenance needs, increasing traffic volumes, expanding highway systems, and rising safety requirements drive continued demand for calcium chloride in de-icing applications requiring ice melting, pre-treatment, and road safety enhancement.

Oil & Gas Industry Expansion Increasing drilling activities, growing unconventional resource development, expanding offshore operations, and rising completion requirements drive adoption of calcium chloride for oil field applications requiring drilling fluids, completion brines, and wellbore stability.

Construction Industry Development Advancing construction activities, increasing cold weather construction, expanding concrete production, and growing infrastructure development drive development of calcium chloride applications requiring concrete acceleration, dust control, and construction efficiency.

Food Processing Growth Growing food production, increasing dairy processing, expanding beverage manufacturing, and rising calcium fortification demands drive adoption of calcium chloride for food applications requiring cheese making, food firming, and nutritional enhancement.

Environmental & Regulatory Compliance

Environmental Safety Management Calcium Chloride has low environmental impact and requires standard environmental practices including application rate control, runoff management, and environmental monitoring ensuring ecosystem protection with consideration for environmental stewardship and established safety procedures from application operations.

Transportation Safety Standards Compliance with standard shipping requirements and material handling guidelines ensures safe transportation and handling in industrial operations with established procedures for hygroscopic material management and safety protocols during transport operations.

Food Safety Standards Adherence to food safety regulations, FDA requirements, and international food standards ensures safe use in food processing applications with established food safety measures and quality assurance systems for food grade calcium chloride.

Regulatory Compliance Standards Compliance with transportation standards, industrial regulations, food safety standards, and international chemical standards ensures safe use in de-icing and processing applications with established regulatory documentation and quality assurance systems for regulated applications.

Performance Advantages & Technical Benefits

✔ Superior De-icing Performance – Exceptional ice melting and freezing point depression with reliable effectiveness

✔ High Hygroscopicity – Excellent moisture absorption and humidity control capabilities

✔ Fast Dissolution – Rapid solubility and excellent processing characteristics

✔ Multiple Form Options – Various physical forms for specific application requirements

✔ Multi-Application Versatility – Suitable for de-icing, industrial, food, and oil field applications

✔ Cost Effectiveness – Excellent performance enhancement and operational cost optimization

✔ Temperature Performance – Effective operation across wide temperature ranges

✔ Quality Consistency – Reliable chemical composition and performance across batches

✔ Environmental Compatibility – Low environmental impact with responsible use practices

✔ Technical Support – Complete application guidance and performance optimization services

✔ Regulatory Compliance – Industry compliant grades with comprehensive documentation

✔ Global Availability – Reliable supply chains and worldwide distribution network

✔ Safety Profile – Established safety record with proper handling procedures

✔ Application Flexibility – Compatible with various application methods and equipment

✔ Proven Performance – Decades of successful use across multiple industries and applications

Our Calcium Chloride products represent industry-leading standards in hygroscopic chemical technology and multi-industry applications, specifically manufactured for demanding de-icing operations, oil field applications, food processing, and industrial processing applications requiring exceptional moisture control, superior de-icing effectiveness, excellent hygroscopic properties, and comprehensive performance optimization. We provide complete technical support, application guidance, and process consultation to ensure optimal results across your specialized de-icing, industrial, food processing, or oil field applications.

For detailed specifications, technical data sheets, or application-specific recommendations, contact our specialized industrial chemicals division. We offer complete support including product selection, application optimization, performance consulting, safety guidance, regulatory assistance, and technical support to maximize effectiveness in your de-icing, industrial, food processing, or oil field applications.

For more information about our products, feel free to Contact Us today.

Reviews

There are no reviews yet.