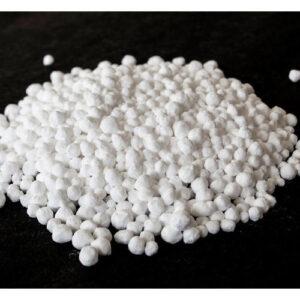

CALCIUM CARBONATE

CALCIUM CARBONATE

Premium Quality Calcium Carbonate – High-Purity Precipitated and Ground Calcium Carbonate, Advanced Functional Filler & Superior Performance Industrial Mineral for Paper Manufacturing, Plastics Production, Paint Formulation, Pharmaceutical Applications & Food Processing Operations

✅ Premium Industrial Mineral – Superior Brightness & High Chemical Purity

✅ Multiple Grade Options – Precipitated, Ground, Pharmaceutical & Food Grades

✅ Excellent Processing Properties – Controlled Particle Size, Superior Performance

✅ Multi-Industry Compatible – Paper, Plastics, Paint, Pharmaceutical & Food Applications

✅ Quality Assured – Established Performance Standards Supporting Optimal Industrial Results

High-Quality Calcium Carbonate

Calcium Carbonate, with chemical formula CaCO₃ and CAS number 471-34-1, commonly known as Precipitated Calcium Carbonate (PCC), Ground Calcium Carbonate (GCC), Chalk, Limestone, or Calcite, available in various grades including precipitated grade (98-99% CaCO₃), ground grade (95-98% CaCO₃), pharmaceutical grade (99-100.5% CaCO₃), food grade (98.5-100.5% CaCO₃), nano grade (99+ % CaCO₃), and coated grade (97-99% CaCO₃), is a white crystalline powder with exceptional chemical purity and outstanding physical properties appearing as fine white powder with excellent brightness characteristics and superior surface area control. Calcium Carbonate is specifically manufactured to provide reliable opacity enhancement, effective cost reduction, superior property modification, and controlled processing characteristics, making it ideal for applications requiring paper brightness improvement, plastic reinforcement, paint opacity enhancement, pharmaceutical tablet formulation, and food processing in paper manufacturing, plastic production, paint and coating industries, pharmaceutical manufacturing, and food processing operations. The compound works through several mechanisms including light scattering for opacity enhancement, volume extension for cost reduction, rheology modification for processing improvement, and surface interaction for property enhancement, providing superior functional performance, reliable processing characteristics, effective cost optimization, and outstanding quality consistency. Calcium Carbonate represents one of the most important industrial minerals across multiple industries, providing exceptional brightness levels, superior particle size distribution, excellent surface properties, and outstanding processing reliability, making it essential for paper manufacturers, plastic processors, paint formulators, pharmaceutical companies, and food processors requiring high-performance mineral fillers and comprehensive technical support.

At Chemicals & Process Equipment Limited, we supply high-performance Calcium Carbonate manufactured under stringent quality control standards and international industrial, pharmaceutical, food, and specialty application specifications. Our comprehensive product range includes various particle sizes, surface treatments, and specialized grades meeting diverse requirements for paper processing, plastic manufacturing, paint formulation, pharmaceutical production, and food processing across global paper, plastic, paint, pharmaceutical, and food markets.

✅ Advanced Mineral Technology – Optimized Particle Size & Multi-Industry Applications

✅ Consistent Quality Standards – Multiple Product Classifications with Comprehensive Documentation

✅ Essential Industrial Mineral – Superior Functional, Processing & Performance Characteristics

✅ Multi-Industry Applications – Paper Manufacturing, Plastics, Paint, Pharmaceutical, Food Processing

✅ Technical Support Package – Complete Application Guidance & Performance Optimization

The global calcium carbonate market was valued at approximately USD 17.8 billion in 2023 and is projected to reach USD 26.1 billion by 2030, growing at a CAGR of 5.6% during the forecast period. Market expansion is driven by increasing paper production, growing plastic manufacturing, expanding paint and coating demands, and rising pharmaceutical and food processing applications.

Technical Specifications & Calcium Carbonate Properties

| Property | Precipitated Grade | Ground Grade | Pharmaceutical Grade | Food Grade | Nano Grade | Coated Grade |

|---|---|---|---|---|---|---|

| CaCO₃ Content (%) | 98.0-99.0 | 95.0-98.0 | 99.0-100.5 | 98.5-100.5 | 99.0+ | 97.0-99.0 |

| Calcium (Ca) Content (%) | 39.2-39.6 | 38.0-39.2 | 39.6-40.2 | 39.4-40.2 | 39.6+ | 38.8-39.6 |

| Loss on Ignition (%) | 43.5-44.5 | 42.0-44.0 | 43.8-44.2 | 43.6-44.4 | 43.9-44.1 | 42.5-44.0 |

| Moisture Content (%) | 0.2-0.8 | 0.3-1.0 | 0.1-0.5 | 0.2-0.6 | 0.1-0.4 | 0.3-0.9 |

| Acid Insoluble Matter (%) | 0.05-0.2 | 0.5-2.0 | 0.02-0.1 | 0.05-0.15 | 0.02-0.08 | 0.1-0.5 |

| Water Soluble Matter (%) | 0.1-0.3 | 0.2-0.5 | 0.05-0.2 | 0.1-0.25 | 0.05-0.15 | 0.15-0.4 |

| pH (10% slurry) | 8.5-9.5 | 8.0-9.0 | 9.0-9.8 | 8.8-9.6 | 9.2-9.8 | 8.2-9.2 |

| Bulk Density (kg/m³) | 400-600 | 800-1200 | 500-700 | 450-650 | 200-400 | 600-1000 |

| True Density (g/cm³) | 2.71 | 2.71 | 2.71 | 2.71 | 2.71 | 2.70-2.71 |

| Particle Size D50 (μm) | 0.5-3.0 | 2.0-20.0 | 1.0-5.0 | 1.5-8.0 | 0.02-0.1 | 1.0-15.0 |

| Particle Size D97 (μm) | 2.0-10.0 | 10.0-50.0 | 5.0-15.0 | 8.0-25.0 | 0.1-0.5 | 5.0-40.0 |

| Surface Area (m²/g) | 15-30 | 2-8 | 8-20 | 5-15 | 50-100 | 3-12 |

| Oil Absorption (ml/100g) | 25-45 | 15-25 | 20-35 | 18-30 | 40-80 | 20-35 |

| Brightness (%) | 94-98 | 85-95 | 96-99 | 95-98 | 96-99 | 88-96 |

| Whiteness Index | 92-96 | 80-92 | 95-98 | 93-97 | 95-98 | 85-94 |

| Yellowness Index | 1.0-3.0 | 2.0-6.0 | 0.5-2.0 | 1.0-2.5 | 0.5-1.5 | 1.5-4.0 |

| Refractive Index | 1.58 | 1.58 | 1.58 | 1.58 | 1.58 | 1.58 |

| Hardness (Mohs) | 3 | 3 | 3 | 3 | 3 | 3 |

| Abrasion (mg/1000 rev) | 5-15 | 8-25 | 3-10 | 5-12 | 2-8 | 6-20 |

| Thermal Decomposition (°C) | 825-840 | 825-840 | 825-840 | 825-840 | 825-840 | 825-840 |

| Specific Heat (J/g·K) | 0.82 | 0.82 | 0.82 | 0.82 | 0.82 | 0.82 |

| Thermal Conductivity (W/m·K) | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 | 2.2 |

| Electrical Resistivity (Ω·cm) | >10¹² | >10¹² | >10¹² | >10¹² | >10¹² | >10¹² |

| Dielectric Constant | 8.5 | 8.5 | 8.5 | 8.5 | 8.5 | 8.5 |

| Crystal System | Hexagonal/Orthorhombic | Hexagonal | Hexagonal/Orthorhombic | Hexagonal/Orthorhombic | Hexagonal/Orthorhombic | Hexagonal |

| Crystal Form | Scalenohedral/Rhombic | Natural | Scalenohedral/Rhombic | Scalenohedral/Rhombic | Spherical/Cubic | Natural/Modified |

| Aspect Ratio | 1:1-3:1 | Variable | 1:1-2:1 | 1:1-2:1 | 1:1 | Variable |

| Shape | Spherical/Rhombic | Irregular | Controlled | Controlled | Spherical | Irregular/Coated |

| Porosity (%) | 5-15 | 2-8 | 3-10 | 4-12 | 20-40 | 3-12 |

| Solubility in Water (g/L) | 0.013 | 0.013 | 0.013 | 0.013 | 0.013 | 0.013 |

| Solubility in HCl | Complete | Complete | Complete | Complete | Complete | Complete |

| Chemical Stability | Excellent | Excellent | Excellent | Excellent | Excellent | Good |

| Thermal Stability | Excellent | Excellent | Excellent | Excellent | Excellent | Excellent |

| UV Resistance | Excellent | Excellent | Excellent | Excellent | Excellent | Good |

| Weather Resistance | Excellent | Excellent | Excellent | Excellent | Excellent | Good |

| Dispersibility | Excellent | Good | Excellent | Excellent | Challenging | Good |

| Rheology Modifier | Yes | Limited | Yes | Yes | Strong | Moderate |

| Thixotropic Effect | Moderate | Low | Moderate | Moderate | High | Low |

| Color | Pure White | White/Off-White | Pure White | Pure White | Pure White | White |

| Appearance | Fine Powder | Powder/Granules | Fine Powder | Fine Powder | Ultrafine Powder | Powder |

| Odor | Odorless | Odorless | Odorless | Odorless | Odorless | Odorless/Slight |

| Taste | Chalky | Chalky | Tasteless | Tasteless | Tasteless | Chalky |

| Toxicity | Non-Toxic | Non-Toxic | Non-Toxic | Non-Toxic | Under Study | Non-Toxic |

| Biocompatibility | Excellent | Good | Excellent | Excellent | Good | Good |

| Food Safety | GRAS | Limited | USP/EP | FDA Approved | Under Review | Limited |

| Iron (Fe) (ppm) | <50 | <200 | <10 | <20 | <20 | <100 |

| Aluminum (Al) (ppm) | <100 | <500 | <50 | <80 | <50 | <300 |

| Silicon (Si) (ppm) | <200 | <2000 | <100 | <150 | <100 | <1000 |

| Magnesium (Mg) (ppm) | <500 | <2000 | <200 | <300 | <200 | <1500 |

| Manganese (Mn) (ppm) | <20 | <100 | <5 | <10 | <5 | <50 |

| Heavy Metals (as Pb) (ppm) | <10 | <30 | <2 | <5 | <5 | <20 |

| Lead (Pb) (ppm) | <2 | <10 | <0.5 | <1 | <1 | <5 |

| Arsenic (As) (ppm) | <1 | <5 | <0.2 | <0.5 | <0.5 | <3 |

| Mercury (Hg) (ppm) | <0.5 | <2 | <0.1 | <0.2 | <0.2 | <1 |

| Cadmium (Cd) (ppm) | <0.5 | <2 | <0.1 | <0.2 | <0.2 | <1 |

| Chromium (Cr) (ppm) | <5 | <20 | <1 | <2 | <2 | <10 |

| Copper (Cu) (ppm) | <5 | <20 | <1 | <2 | <2 | <10 |

| Zinc (Zn) (ppm) | <10 | <50 | <2 | <5 | <5 | <25 |

| Nickel (Ni) (ppm) | <5 | <20 | <1 | <2 | <2 | <10 |

| Strontium (Sr) (ppm) | <100 | <500 | <50 | <80 | <50 | <300 |

| Barium (Ba) (ppm) | <50 | <200 | <10 | <20 | <20 | <100 |

| Fluoride (F) (ppm) | <50 | <100 | <10 | <20 | <20 | <80 |

| Chloride (Cl) (ppm) | <100 | <200 | <50 | <80 | <50 | <150 |

| Sulfate (SO₄) (ppm) | <200 | <500 | <100 | <150 | <100 | <350 |

| Phosphate (PO₄) (ppm) | <50 | <100 | <20 | <30 | <20 | <80 |

| Organic Matter (%) | <0.1 | <0.3 | <0.05 | <0.08 | <0.05 | <0.2 |

| Residue on Ignition (%) | <0.2 | <0.5 | <0.1 | <0.15 | <0.1 | <0.3 |

| Microbial Count (CFU/g) | <1000 | <10000 | <100 | <500 | <100 | <5000 |

| Yeast & Mold (CFU/g) | <100 | <1000 | <10 | <50 | <10 | <500 |

| E. coli | Negative | Negative | Negative | Negative | Negative | Negative |

| Salmonella | Negative | Negative | Negative | Negative | Negative | Negative |

| Storage Temperature (°C) | 15-35 | 10-40 | 15-30 | 15-35 | 15-25 | 10-35 |

| Storage Humidity (%) | <70 | <80 | <60 | <65 | <50 | <75 |

| Packaging | Bags/Bulk | Bags/Bulk | Bags/Drums | Bags/Boxes | Drums/Bottles | Bags/Bulk |

| Shelf Life (months) | 36 | 60 | 24 | 36 | 18 | 48 |

| Container Material | PE/PP/Paper | PE/PP/Paper | PE/PP/Glass | PE/PP | HDPE/Glass | PE/PP/Paper |

| Transport Class | Non-Hazardous | Non-Hazardous | Non-Hazardous | Non-Hazardous | Non-Hazardous | Non-Hazardous |

| Regulatory Status | Industrial | Industrial | USP/EP/BP | FDA/GRAS | Under Review | Industrial |

| GMP Compliance | No | No | Yes | Yes | Limited | No |

| Kosher Certified | Limited | No | Available | Yes | No | No |

| Halal Certified | Limited | No | Available | Yes | No | No |

| Organic Certified | No | No | No | Limited | No | No |

| ISO Certification | Yes | Yes | Yes | Yes | Yes | Yes |

| Application Temperature (°C) | 20-200 | 20-150 | 20-80 | 20-120 | 20-100 | 20-180 |

| Processing pH Range | 7-11 | 7-10 | 8-10 | 8-10 | 8-11 | 7-10 |

| Compatibility | Excellent | Good | Excellent | Excellent | Good | Good |

| Reactivity | Low | Low | Low | Low | Moderate | Low |

| Dispersing Agent Required | Optional | Recommended | Optional | Optional | Required | Recommended |

| Surface Treatment | None | None | Optional | Optional | Required | Stearic Acid |

| Coating Type | None | None | None | None | Silane/Titanate | Fatty Acid |

| Coating Level (%) | 0 | 0 | 0 | 0 | 1-3 | 0.5-2.0 |

| Hydrophobicity | Hydrophilic | Hydrophilic | Hydrophilic | Hydrophilic | Variable | Hydrophobic |

| Oil Affinity | Low | Low | Low | Low | Variable | High |

| Polymer Compatibility | Good | Good | Excellent | Good | Variable | Excellent |

| Reinforcement Effect | Moderate | Limited | Moderate | Moderate | High | Good |

| Cost Effectiveness | High | Very High | Medium | Medium-High | Low | Medium |

| Environmental Impact | Low | Low | Low | Low | Unknown | Low |

| Recyclability | Excellent | Excellent | Excellent | Excellent | Good | Good |

| Carbon Footprint | Low | Medium | Low | Low | Medium | Medium |

| Technical Support | Enhanced | Standard | Premium | Enhanced | Premium | Standard |

| Application Training | Yes | Limited | Yes | Yes | Yes | Limited |

| Custom Development | Yes | Limited | Yes | Yes | Yes | No |

| Analytical Support | Full | Basic | Full | Full | Full | Basic |

| Quality Guarantee | Yes | Yes | Yes | Yes | Limited | Yes |

| Performance Testing | Available | Optional | Required | Available | Required | Optional |

| Pilot Trials | Yes | Limited | Yes | Yes | Yes | Limited |

| Global Availability | Worldwide | Worldwide | Regional | Worldwide | Limited | Worldwide |

| Supply Reliability | Excellent | Excellent | Very Good | Excellent | Good | Very Good |

| Lead Time (days) | 7-14 | 5-10 | 14-21 | 7-14 | 21-30 | 10-17 |

| Minimum Order (kg) | 1000 | 500 | 100 | 500 | 50 | 1000 |

| Bulk Pricing | Available | Available | Limited | Available | No | Available |

| Contract Terms | Flexible | Flexible | Specialized | Flexible | Premium | Standard |

Available Product Types:

- Precipitated Calcium Carbonate (PCC) for high-performance applications

- Ground Calcium Carbonate (GCC) for cost-effective solutions

- Pharmaceutical Grade for drug formulation and medical applications

- Food Grade for food processing and nutritional supplements

- Nano Grade for advanced applications and specialty formulations

- Coated Grade for enhanced polymer compatibility

- Ultrafine Grade for paint and coating applications

- Paper Grade for brightness and opacity enhancement

- Plastic Grade for reinforcement and cost reduction

- Paint Grade for opacity and rheology control

- Rubber Grade for reinforcement and processing aid

- Adhesive Grade for formulation enhancement

Specialized Application Solutions:

- Paper coating and filling system optimization

- Plastic compound formulation and processing enhancement

- Paint and coating rheology modification and opacity improvement

- Pharmaceutical tablet formulation and excipient optimization

- Food processing and nutritional supplement development

- Polymer modification and performance enhancement

- Surface treatment and coating application development

- Particle size optimization and distribution control

- Quality control systems and analytical testing protocols

- Process optimization and efficiency improvement consulting

- Technical training and application development programs

- Performance monitoring and troubleshooting services

Paper Manufacturing Applications

Paper Coating Operations Paper manufacturers utilize Calcium Carbonate for paper coating, brightness enhancement, and print quality improvement requiring paper coating grade specifications. Paper technologists employ calcium carbonate for opacity development, surface smoothness applications requiring print quality, ink absorption, and paper performance in coated paper production operations.

Paper Filling Applications Paper mills use Calcium Carbonate for paper filling, bulk enhancement, and cost reduction requiring paper filler grade specifications. Paper engineers employ calcium carbonate for formation improvement, basis weight control applications requiring paper quality, manufacturing efficiency, and cost optimization in filled paper production.

Newsprint Production Newsprint manufacturers utilize Calcium Carbonate for brightness improvement, opacity enhancement, and print quality requiring newsprint grade specifications. Production specialists employ calcium carbonate for ink opacity, print density applications requiring readability, print quality, and cost effectiveness in newsprint manufacturing operations.

Tissue Paper Manufacturing Tissue producers use Calcium Carbonate for softness enhancement, absorbency improvement, and bulk development requiring tissue grade specifications. Tissue technologists employ calcium carbide for formation control, wet strength applications requiring absorbency, softness, and performance characteristics in tissue paper production. For comprehensive information about calcium carbonate properties, applications, and safety guidelines, visit the European Food Safety Authority Scientific Opinion which provides detailed guidance on calcium carbonate food applications, safety assessments, and regulatory standards for food-grade calcium carbonate use.

Plastics and Polymer Applications

PVC Compound Manufacturing Plastic processors utilize Calcium Carbonate for PVC compounding, cost reduction, and property modification requiring plastic grade specifications. Polymer engineers employ calcium carbonate for impact modification, processing aid applications requiring mechanical properties, cost optimization, and processing efficiency in PVC compound production.

Polyethylene Processing Polyethylene manufacturers use Calcium Carbonate for film production, blown film applications, and property enhancement requiring film grade specifications. Film technologists employ calcium carbonate for breathability, opacity applications requiring film properties, processing characteristics, and performance optimization in polyethylene film production.

Polypropylene Modification Polypropylene processors utilize Calcium Carbonate for compound modification, reinforcement, and cost reduction requiring PP grade specifications. Compounding specialists employ calcium carbonate for stiffness improvement, dimensional stability applications requiring mechanical properties, processing efficiency, and cost effectiveness in polypropylene compounding.

Thermoset Applications Thermoset manufacturers use Calcium Carbonate for resin modification, filler applications, and performance enhancement requiring thermoset grade specifications. Resin formulators employ calcium carbonate for viscosity control, shrinkage reduction applications requiring cure characteristics, mechanical properties, and processing optimization in thermoset production.

Paint and Coating Applications

Architectural Paint Formulation Paint manufacturers utilize Calcium Carbonate for opacity enhancement, cost reduction, and rheology modification requiring paint grade specifications. Paint formulators employ calcium carbonate for hiding power, texture development applications requiring coverage, durability, and application characteristics in architectural paint production.

Industrial Coating Systems Coating producers use Calcium Carbonate for corrosion protection, barrier properties, and performance enhancement requiring industrial coating grade specifications. Coating chemists employ calcium carbonate for film build, surface properties applications requiring protection performance, adhesion, and durability in industrial coating formulations.

Powder Coating Manufacturing Powder coating manufacturers utilize Calcium Carbonate for texture control, appearance modification, and cost optimization requiring powder coating grade specifications. Powder technologists employ calcium carbonate for flow properties, surface finish applications requiring coating quality, application characteristics, and performance optimization in powder coating production.

Marine Paint Systems Marine coating producers use Calcium Carbonate for antifouling enhancement, durability improvement, and performance optimization requiring marine grade specifications. Marine coating specialists employ calcium carbonate for film integrity, weather resistance applications requiring marine protection, service life, and environmental compliance in marine paint formulations.

Pharmaceutical Applications

Tablet Manufacturing Pharmaceutical companies utilize Calcium Carbonate for tablet formulation, excipient applications, and drug delivery requiring pharmaceutical grade specifications. Pharmaceutical formulators employ calcium carbonate for tablet hardness, disintegration applications requiring drug release, bioavailability, and manufacturing compliance in tablet production operations.

Antacid Formulations Pharmaceutical manufacturers use Calcium Carbonate for antacid production, acid neutralization, and therapeutic applications requiring USP grade specifications. Pharmaceutical chemists employ calcium carbonate for buffering capacity, neutralization applications requiring therapeutic efficacy, safety, and regulatory compliance in antacid formulations.

Dietary Supplement Production Supplement manufacturers utilize Calcium Carbonate for calcium supplementation, nutritional enhancement, and health applications requiring food grade specifications. Nutritional scientists employ calcium carbonate for bioavailability, absorption applications requiring nutritional value, safety, and regulatory compliance in dietary supplement production.

Pharmaceutical Coating Tablet coating operations use Calcium Carbonate for coating formulation, appearance enhancement, and protection requiring coating grade specifications. Coating specialists employ calcium carbonate for film formation, color development applications requiring tablet protection, appearance, and patient compliance in pharmaceutical coating operations.

Food Processing Applications

Food Fortification Food manufacturers utilize Calcium Carbonate for calcium fortification, nutritional enhancement, and health benefits requiring food grade specifications. Food technologists employ calcium carbonate for bioavailability, stability applications requiring nutritional value, taste neutrality, and regulatory compliance in fortified food production.

Baking Applications Baking industries use Calcium Carbonate for dough conditioning, texture improvement, and calcium enrichment requiring baking grade specifications. Baking specialists employ calcium carbonate for dough handling, volume enhancement applications requiring texture, nutritional value, and processing characteristics in baked goods production.

Confectionery Manufacturing Confectionery producers utilize Calcium Carbonate for texture modification, whitening agent, and processing aid requiring confectionery grade specifications. Confectionery technologists employ calcium carbonate for appearance, mouthfeel applications requiring product quality, shelf life, and consumer acceptance in confectionery production.

Dairy Product Processing Dairy manufacturers use Calcium Carbonate for calcium enrichment, pH adjustment, and nutritional enhancement requiring dairy grade specifications. Dairy technologists employ calcium carbonate for protein stabilization, nutritional fortification applications requiring product quality, nutritional value, and regulatory compliance in dairy processing operations.

Quality Control & Testing Procedures

Comprehensive Quality Assurance Every production batch undergoes extensive testing to ensure compliance with calcium carbonate standards, industrial requirements, pharmaceutical specifications, food grade standards, and international quality standards. Our quality control laboratory employs advanced analytical techniques including particle size analysis, chemical composition testing, and comprehensive performance evaluation.

Quality assurance procedures include:

- Calcium carbonate content determination using complexometric titration

- Calcium content analysis using atomic absorption spectroscopy

- Loss on ignition testing using high-temperature furnace methods

- Moisture content determination using Karl Fischer titration

- Acid insoluble matter analysis using acid digestion methods

- Water soluble matter testing using extraction procedures

- Particle size distribution analysis using laser diffraction

- Surface area measurement using BET nitrogen adsorption

- Oil absorption testing using standardized procedures

- Brightness measurement using reflectance spectroscopy

- Whiteness index determination using colorimetric methods

- pH measurement using calibrated electrodes

- Heavy metals testing using ICP-MS and atomic absorption

- Trace element analysis using instrumental methods

- Microbiological testing using standard culture methods

- Crystal structure analysis using X-ray diffraction

- Thermal analysis using TGA and DSC methods

- Scanning electron microscopy for morphology analysis

- Chemical reactivity testing using standard procedures

- Dispersion characteristics evaluation using rheology testing

- Polymer compatibility testing using mixing trials

- Performance testing using application-specific protocols

- Stability testing using accelerated aging protocols

- Environmental compliance verification using standard methods

- Quality system compliance using ISO standards

- Customer application support using pilot testing

- Technical consultation using expert evaluation

- Continuous improvement using statistical process control

Storage & Handling Procedures Implement proper storage conditions including moisture protection, temperature control, contamination prevention, proper ventilation, and comprehensive handling procedures for maintaining Calcium Carbonate quality and ensuring safe processing throughout storage and application periods while following all best practices for mineral filler handling.

Market Applications & Industry Trends

Paper Industry Growth Growing global paper production, increasing packaging demands, expanding digital printing requirements, and rising quality standards drive continued demand for calcium carbonate in paper applications requiring brightness enhancement, opacity improvement, and cost optimization.

Plastics Market Expansion Increasing plastic production, growing packaging applications, expanding automotive components, and rising construction materials demand drive adoption of calcium carbonate for plastic applications requiring cost reduction, property modification, and processing enhancement.

Paint Industry Development Advancing paint technology, increasing construction activities, expanding industrial coating applications, and growing architectural demands drive development of calcium carbonate applications requiring opacity enhancement, rheology control, and cost effectiveness.

Pharmaceutical Market Growth Growing pharmaceutical production, increasing generic drug manufacturing, expanding supplement markets, and rising healthcare demands drive adoption of calcium carbonate for pharmaceutical applications requiring excipient functionality, therapeutic efficacy, and regulatory compliance.

Environmental & Regulatory Compliance

Health and Safety Management Calcium Carbonate is generally recognized as safe (GRAS) and requires standard industrial hygiene practices including dust control, personal protective equipment, and proper ventilation ensuring worker protection with consideration for nuisance dust exposure and established safety procedures from handling and processing operations.

Transportation Safety Standards Compliance with standard shipping requirements and material handling guidelines ensures safe transportation and handling in industrial operations with established procedures for bulk material management and dust control during transport operations.

Environmental Protection Standards Adherence to environmental regulations, dust emission controls, and waste management requirements ensures responsible use in manufacturing applications with established environmental protection measures and sustainable mining practices for calcium carbonate production.

Regulatory Compliance Standards Compliance with FDA, USP, EP, and international food and pharmaceutical standards ensures safe use in food and pharmaceutical applications with established regulatory documentation and quality assurance systems for regulated applications.

Performance Advantages & Technical Benefits

✔ Superior Brightness – Exceptional whiteness and opacity enhancement with reliable performance

✔ Controlled Particle Size – Precise particle distribution for optimal application performance

✔ Chemical Purity – High-grade mineral content ensuring consistent processing results

✔ Multiple Grade Options – Various specifications for specific application requirements

✔ Multi-Application Versatility – Suitable for paper, plastic, paint, pharmaceutical, and food applications

✔ Cost Effectiveness – Excellent volume extension and cost reduction capabilities

✔ Processing Enhancement – Improved rheology, flow, and processing characteristics

✔ Quality Consistency – Reliable mineral composition and performance across batches

✔ Surface Properties – Excellent surface area control and modification capabilities

✔ Technical Support – Complete application guidance and formulation optimization services

✔ Regulatory Compliance – Industry compliant grades with comprehensive documentation

✔ Global Availability – Reliable supply chains and worldwide distribution network

✔ Environmental Safety – Non-toxic, sustainable mineral with excellent safety profile

✔ Thermal Stability – Excellent high-temperature performance and stability

✔ Chemical Compatibility – Compatible with various polymer systems and formulations

Our Calcium Carbonate products represent industry-leading standards in functional filler technology and mineral applications, specifically manufactured for demanding paper processing operations, plastic manufacturing, paint formulation, pharmaceutical production, and food processing applications requiring exceptional brightness, controlled particle size, superior surface properties, and comprehensive performance optimization. We provide complete technical support, application guidance, and formulation consultation to ensure optimal results across your specialized paper, plastic, paint, pharmaceutical, or food processing applications.

For detailed specifications, technical data sheets, or application-specific recommendations, contact our specialized minerals division. We offer complete support including product selection, formulation optimization, application consulting, performance monitoring, regulatory guidance, and technical assistance to maximize effectiveness in your paper manufacturing, plastic processing, paint formulation, pharmaceutical production, or food processing applications.

For more information about our products, feel free to Contact Us today.

Reviews

There are no reviews yet.