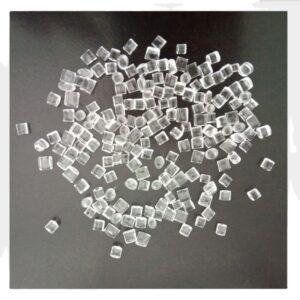

Virgin Polymethyl Methacrylate PMMA Resin Granules

Virgin Polymethyl Methacrylate PMMA Resin Granules

Premium Grade Virgin PMMA Resin Granules – High-Performance Thermoplastic for Optical Applications, Medical Devices & Industrial Manufacturing

Virgin Polymethyl Methacrylate (PMMA) Resin Granules are premium-grade thermoplastic polymers essential for optical lens manufacturing, medical device production, automotive components, and precision molding applications requiring superior optical clarity and mechanical performance.

✅ Virgin Grade Quality – 100% Pure PMMA with Superior Optical Properties

✅ Medical Grade Certified – USP Class VI & ISO 10993 Biocompatibility

✅ Optical Applications – Lens, Lightguides & Precision Optical Components

✅ Excellent Processability – Injection Molding & Extrusion Compatibility

✅ Quality Assurance – Comprehensive Testing & Batch Consistency

Virgin Polymethyl Methacrylate PMMA Resin Granules for Optical & Medical Applications

Virgin Polymethyl Methacrylate (PMMA) Resin Granules represent advanced thermoplastic technology specifically formulated to deliver superior performance in optical lens manufacturing, medical device production, automotive lighting, precision molding, and specialty applications requiring high-performance acrylic polymers with exceptional optical clarity and mechanical properties. This premium-grade virgin PMMA provides outstanding light transmission, optimal impact resistance, and reliable processing characteristics across injection molding, extrusion processing, sheet manufacturing, fiber optics, and specialty polymer applications demanding pharmaceutical-grade quality and regulatory compliance standards.

At Chemicals & Process Equipment Limited, we supply high-quality Virgin Polymethyl Methacrylate PMMA Resin Granules manufactured under strict pharmaceutical and optical-grade standards with comprehensive quality control and international certifications. Our complete polymer product range includes medical-grade PMMA, optical-grade formulations, and specialty acrylic compounds meeting diverse requirements for medical device manufacturing, optical component production, automotive applications, and precision molding operations across global medical, optical, automotive, and specialty manufacturing markets.

For comprehensive information about acrylic polymer chemistry and processing applications, we recommend exploring Acrylic Plastics Technology Handbook by the Society of Plastics Engineers, providing authoritative guidance on PMMA properties and industrial applications.

✅ Advanced Polymer Technology – Superior Optical Clarity & Mechanical Performance

✅ Professional Quality Standards – Medical Grade & Optical Specifications

✅ Complete Processing Solution – High Performance & Consistent Results

✅ Versatile Manufacturing Applications – Medical, Optical, Automotive & Industrial

✅ Expert Technical Support – Processing Guidance & Application Development

The Global PMMA Market is valued at approximately $5.8 billion in 2025 and is projected to reach $8.1 billion by 2030, exhibiting a CAGR of 6.9% during the forecast period. This growth is driven by increasing automotive lighting demand, expanding medical device applications, growing optical component requirements, and rising adoption of specialty acrylic materials across international manufacturing markets.

Technical Specifications & PMMA Properties

| Property | Medical Grade | Optical Grade | Automotive Grade | General Purpose |

|---|---|---|---|---|

| Molecular Weight (Mw) | 90,000-120,000 | 100,000-150,000 | 80,000-110,000 | 70,000-100,000 |

| Melt Flow Index (230°C/3.8kg) | 2-8 g/10min | 1-5 g/10min | 5-15 g/10min | 8-25 g/10min |

| Density @ 23°C | 1.18-1.19 g/cm³ | 1.18-1.19 g/cm³ | 1.17-1.19 g/cm³ | 1.17-1.20 g/cm³ |

| Tensile Strength | ≥70 MPa | ≥75 MPa | ≥65 MPa | ≥60 MPa |

| Flexural Strength | ≥110 MPa | ≥120 MPa | ≥105 MPa | ≥100 MPa |

| Impact Strength (Notched Izod) | ≥18 kJ/m² | ≥20 kJ/m² | ≥16 kJ/m² | ≥15 kJ/m² |

| Light Transmission | ≥92% | ≥93% | ≥91% | ≥90% |

| Haze | ≤1% | ≤0.5% | ≤1.5% | ≤2% |

| Yellowness Index | ≤1.5 | ≤1.0 | ≤2.0 | ≤3.0 |

| Refractive Index | 1.491-1.492 | 1.491-1.492 | 1.490-1.493 | 1.490-1.494 |

| Glass Transition Temperature | 105-110°C | 108-112°C | 100-108°C | 95-105°C |

| Heat Deflection Temperature | 95-105°C | 100-110°C | 90-100°C | 85-95°C |

| Vicat Softening Temperature | 110-120°C | 115-125°C | 105-115°C | 100-110°C |

| Processing Temperature | 210-250°C | 220-260°C | 200-240°C | 190-230°C |

| Water Absorption (24hrs) | ≤0.3% | ≤0.2% | ≤0.4% | ≤0.5% |

| Chemical Resistance | Excellent | Excellent | Good | Good |

| UV Resistance | Excellent | Superior | Good | Fair |

| Residual Monomer | ≤0.1% | ≤0.05% | ≤0.2% | ≤0.5% |

| Heavy Metals (ppm) | ≤10 | ≤5 | ≤20 | ≤50 |

| Biocompatibility | USP Class VI | N/A | N/A | N/A |

| Appearance | Clear Granules | Clear Granules | Clear Granules | Clear Granules |

| Particle Size | 2-4 mm | 2-4 mm | 3-5 mm | 2-6 mm |

| Moisture Content | ≤0.05% | ≤0.03% | ≤0.08% | ≤0.1% |

| Storage Stability | 24 months | 24 months | 18 months | 12 months |

| Shelf Life | 2 years | 2 years | 1.5 years | 1 year |

| Packaging | Moisture-Proof Bags | Optical Grade Bags | Industrial Bags | Standard Bags |

Available Product Grades:

- Medical grade PMMA for biomedical applications and implants

- Optical grade PMMA for lens and precision optical components

- Automotive grade PMMA for lighting and interior applications

- General purpose PMMA for standard molding applications

- High flow PMMA for thin-wall and complex molding

- Impact modified PMMA for enhanced toughness applications

- UV stabilized PMMA for outdoor and weathering applications

- Custom formulations for specific application requirements

Specialized Processing Capabilities:

- Injection molding grades for complex geometries

- Extrusion grades for sheet and profile applications

- Blow molding grades for hollow containers

- Fiber spinning grades for optical fiber applications

- Cast molding grades for thick section applications

- 3D printing grades for additive manufacturing

- Thermoforming grades for formed sheet applications

- Machining grades for precision mechanical components

Medical Device Applications

Orthopedic Implants Medical device manufacturers utilize medical-grade PMMA for bone cement, joint replacements, and orthopedic implants requiring USP Class VI biocompatibility and long-term stability. Orthopedic surgery employs PMMA for reliable fixation and patient safety.

Dental Applications Dental manufacturers use PMMA for denture bases, orthodontic appliances, and dental prosthetics requiring biocompatibility and aesthetic properties. Dental restoration employs PMMA for patient comfort and clinical performance.

Drug Delivery Systems Pharmaceutical companies utilize PMMA for controlled release systems, drug delivery devices, and pharmaceutical packaging requiring chemical resistance and regulatory compliance. Drug delivery employs PMMA for therapeutic effectiveness and patient safety.

Surgical Instruments Medical device manufacturers use PMMA for surgical instruments, disposable devices, and medical equipment requiring sterilization compatibility and mechanical reliability. Surgical applications employ PMMA for precision and safety standards.

Optical Component Applications

Precision Lenses Optical manufacturers utilize optical-grade PMMA for camera lenses, microscope components, and precision optics requiring exceptional optical clarity and dimensional stability. Optical systems employ PMMA for superior performance and reliability.

Light Guides & Fiber Optics Fiber optic manufacturers use PMMA for optical fibers, light guides, and illumination systems requiring excellent light transmission and flexibility. Optical communication employs PMMA for signal clarity and system reliability.

LED Optics LED manufacturers utilize PMMA for LED lenses, diffusers, and lighting components requiring optimal light management and thermal stability. LED lighting employs PMMA for efficiency and performance optimization.

Display Applications Display manufacturers use PMMA for LCD panels, touch screens, and display components requiring optical clarity and scratch resistance. Electronic displays employ PMMA for visual quality and durability.

Automotive Industry Applications

Automotive Lighting Automotive manufacturers utilize automotive-grade PMMA for headlight lenses, taillights, and interior lighting requiring impact resistance and weather durability. Automotive lighting employs PMMA for safety and aesthetic performance.

Interior Components Automotive suppliers use PMMA for dashboard components, instrument panels, and interior trim requiring clarity, durability, and processing versatility. Automotive interiors employ PMMA for design flexibility and quality.

Glazing Applications Automotive manufacturers utilize PMMA for sunroofs, windows, and glazing applications requiring optical clarity and impact resistance. Automotive glazing employs PMMA for weight reduction and safety standards.

Exterior Components Automotive suppliers use PMMA for exterior trim, logos, and decorative elements requiring weather resistance and aesthetic appeal. Automotive exteriors employ PMMA for brand identity and durability.

Construction & Architecture Applications

Architectural Glazing Construction companies utilize PMMA for architectural glazing, skylights, and building facades requiring optical clarity and weather resistance. Architectural applications employ PMMA for design innovation and energy efficiency.

Safety Glazing Security manufacturers use PMMA for bulletproof glazing, protective barriers, and safety applications requiring impact resistance and optical clarity. Security glazing employs PMMA for protection and visibility.

Signage & Displays Sign manufacturers utilize PMMA for illuminated signs, displays, and advertising applications requiring durability and light transmission. Commercial signage employs PMMA for visibility and longevity.

Decorative Applications Architectural suppliers use PMMA for decorative panels, artistic installations, and design elements requiring aesthetic appeal and processing versatility. Decorative applications employ PMMA for creative expression and durability.

Electronics & Technology Applications

Electronic Housings Electronics manufacturers utilize PMMA for device housings, protective covers, and electronic components requiring clarity, durability, and electrical properties. Electronics applications employ PMMA for protection and aesthetics.

Semiconductor Applications Semiconductor manufacturers use PMMA for photoresist applications, lithography processes, and microelectronics requiring precision and chemical resistance. Semiconductor processing employs PMMA for manufacturing accuracy.

Optical Storage Media Media manufacturers utilize PMMA for optical discs, data storage, and information systems requiring optical clarity and dimensional stability. Data storage employs PMMA for reliability and performance.

Telecommunications Telecommunications companies use PMMA for fiber optic components, communication devices, and networking equipment requiring signal clarity and durability. Telecommunications employ PMMA for connectivity and performance.

Consumer Products Applications

Household Items Consumer goods manufacturers utilize PMMA for household products, kitchenware, and appliances requiring clarity, durability, and safety. Consumer products employ PMMA for functionality and aesthetic appeal.

Recreational Products Sports equipment manufacturers use PMMA for recreational products, sports equipment, and leisure items requiring impact resistance and weather durability. Recreation applications employ PMMA for performance and safety.

Personal Care Products Cosmetic manufacturers utilize PMMA for cosmetic packaging, beauty accessories, and personal care items requiring clarity, chemical resistance, and aesthetic appeal. Personal care employs PMMA for product presentation and functionality.

Toys & Games Toy manufacturers use PMMA for educational toys, games, and children’s products requiring safety, durability, and visual appeal. Toy applications employ PMMA for child safety and entertainment value.

Industrial Manufacturing Applications

Machine Components Industrial manufacturers utilize PMMA for machine parts, protective covers, and industrial equipment requiring mechanical strength and chemical resistance. Industrial machinery employs PMMA for operational reliability and maintenance efficiency.

Process Equipment Chemical processing companies use PMMA for process vessels, sight glasses, and chemical equipment requiring chemical resistance and optical clarity. Industrial processing employs PMMA for operational monitoring and safety.

Precision Molding Molding companies utilize PMMA for precision components, technical parts, and specialty products requiring dimensional accuracy and surface quality. Precision molding employs PMMA for quality and performance standards.

Laboratory Equipment Laboratory suppliers use PMMA for lab equipment, analytical instruments, and scientific apparatus requiring chemical resistance and optical clarity. Laboratory applications employ PMMA for analytical accuracy and safety.

Marine & Aerospace Applications

Marine Glazing Marine manufacturers utilize PMMA for boat windows, marine glazing, and nautical components requiring saltwater resistance and optical clarity. Marine applications employ PMMA for visibility and durability in harsh environments.

Aerospace Components Aerospace manufacturers use PMMA for aircraft windows, cockpit displays, and aerospace components requiring lightweight properties and regulatory compliance. Aerospace applications employ PMMA for safety and performance standards.

Underwater Applications Underwater equipment manufacturers utilize PMMA for submarine windows, underwater cameras, and marine research equipment requiring pressure resistance and optical clarity. Underwater applications employ PMMA for deep-sea operations and research.

Weather Protection Outdoor equipment manufacturers use PMMA for weather shields, protective covers, and outdoor equipment requiring UV resistance and durability. Weather protection employs PMMA for long-term outdoor performance.

Processing Guidelines & Technical Recommendations

Injection Molding Parameters Process PMMA at barrel temperatures of 210-250°C with mold temperatures of 60-80°C. Use moderate injection speeds and pressures to prevent material degradation and ensure optimal part quality.

Extrusion Processing Utilize extrusion temperatures of 200-240°C with proper screw design for PMMA processing. Maintain consistent temperature profiles and minimize residence time to prevent thermal degradation.

Thermoforming Conditions Heat PMMA sheets to 160-180°C for thermoforming operations. Use appropriate heating rates and forming pressures to achieve optimal part formation and minimize stress.

Drying Requirements Pre-dry PMMA granules at 80-90°C for 4-6 hours to reduce moisture content below 0.05%. Use dehumidifying dryers for consistent processing and optimal part quality.

Quality Control & Manufacturing Standards

Comprehensive Quality Assurance Every production batch undergoes rigorous testing to ensure molecular weight, optical properties, mechanical characteristics, and processing performance. Our quality control laboratory employs advanced analytical methods including GPC, DSC, optical testing, and mechanical analysis.

Quality assurance procedures include:

- Molecular weight determination using gel permeation chromatography

- Melt flow index measurement using standardized capillary rheometer

- Optical property testing including light transmission and haze measurement

- Mechanical property testing including tensile and impact strength

- Thermal analysis using differential scanning calorimetry

- Residual monomer analysis using gas chromatography

- Heavy metal content determination using ICP-MS analysis

- Moisture content analysis using Karl Fischer titration

- Particle size analysis using laser diffraction methods

- Color measurement using spectrophotometry

- Biocompatibility testing for medical grade materials

- Processing evaluation using injection molding trials

- Certificate of analysis preparation with complete test results

Storage & Handling Procedures

Proper Storage Conditions Store PMMA granules in cool, dry, well-ventilated areas away from moisture, heat sources, and UV radiation. Maintain storage temperature below 30°C and relative humidity below 50% for optimal product stability and quality preservation.

Material Handling Safety Use appropriate personal protective equipment including safety glasses and protective clothing when handling PMMA products. Ensure adequate ventilation during processing and follow established safety protocols for thermoplastic handling.

Moisture Protection Implement moisture control through sealed packaging, desiccant systems, and climate-controlled storage. Monitor humidity levels and use proper drying procedures before processing to prevent quality issues.

Processing Equipment Care Use corrosion-resistant processing equipment designed for thermoplastic materials. Implement proper cleaning procedures and temperature control to prevent contamination and ensure consistent processing.

Environmental & Safety Compliance

Medical Device Regulations PMMA complies with FDA medical device regulations, USP Class VI biocompatibility standards, and ISO 10993 biological evaluation requirements ensuring safe use in medical and pharmaceutical applications.

Automotive Standards Adherence to automotive industry standards including ASTM, SAE, and ECE regulations ensuring appropriate use in automotive lighting, glazing, and component applications.

Food Contact Compliance Food-grade PMMA formulations comply with FDA food contact regulations and EU food contact material standards ensuring safe use in food packaging and processing equipment.

Environmental Responsibility Compliance with environmental regulations, waste management standards, and sustainability practices ensuring responsible manufacturing and supporting circular economy principles through recycling initiatives.

Performance Benefits & Technical Advantages

✔ Virgin Grade Quality – 100% pure PMMA with superior properties and performance

✔ Medical Grade Certified – USP Class VI biocompatibility for medical applications

✔ Exceptional Optical Clarity – Outstanding light transmission and optical properties

✔ Superior Processability – Excellent molding and processing characteristics

✔ Chemical Resistance – Outstanding resistance to chemicals and weathering

✔ Dimensional Stability – Excellent dimensional accuracy and long-term stability

✔ UV Resistance – Superior resistance to UV radiation and outdoor weathering

✔ Regulatory Compliance – Meets international medical and automotive standards

✔ Technical Support – Expert guidance and application development assistance

✔ Consistent Quality – Rigorous quality control and batch-to-batch consistency

✔ Versatile Applications – Suitable for medical, optical, automotive, and industrial uses

✔ Storage Stability – Extended shelf life with proper handling conditions

Market Applications & Industry Trends

Medical Device Growth Expanding medical device industry and increasing demand for biocompatible materials drive growing demand for medical-grade PMMA in orthopedic implants, dental applications, and drug delivery systems across global healthcare markets.

Automotive Lighting Evolution Advancing automotive lighting technology and increasing LED adoption support demand for high-performance PMMA in automotive lighting, interior components, and glazing applications worldwide.

Optical Technology Advancement Growing optical component requirements and increasing fiber optic infrastructure drive demand for optical-grade PMMA in telecommunications, displays, and precision optical applications.

Sustainable Manufacturing Increasing focus on sustainable materials and circular economy principles support development of recycled and bio-based PMMA formulations for environmentally responsible manufacturing.

Our Virgin Polymethyl Methacrylate PMMA Resin Granules represent industry-leading standards in thermoplastic technology and optical performance, specifically formulated for demanding medical device manufacturing, optical component production, automotive applications, and precision molding operations. We provide comprehensive technical support, processing guidance, and regulatory compliance assistance to ensure maximum performance and quality across your medical, optical, automotive, or specialty manufacturing applications.

For detailed specifications, processing guidelines, or application-specific recommendations, contact our technical specialists. We offer complete support including material selection, processing optimization, and quality assurance assistance to maximize effectiveness in your medical device manufacturing, optical component production, automotive applications, or specialty polymer processing operations.

For more information about our products, feel free to Contact Us today.

Reviews

There are no reviews yet.