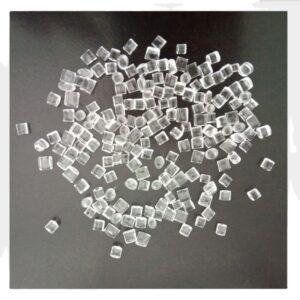

PPA Resin (Polyphthalamide)

PPA Resin (Polyphthalamide)

Premium Quality PPA Resin – Semi-Crystalline Aromatic Polyamide for Automotive Manufacturing, Electronics Components, Aerospace Applications & High-Temperature Engineering Solutions

PPA Resin (Polyphthalamide) are high-performance semi-crystalline aromatic polyamides extensively utilized in automotive manufacturing, electronics components, aerospace applications, industrial equipment, and demanding engineering operations requiring exceptional heat resistance, chemical resistance, and superior mechanical properties.

✅ Ultra-High Performance PPA Resin – Superior Heat Resistance & Multi-Industry Engineering Performance

✅ Multiple Grade Options – Injection Molding, Glass-Filled, Mineral-Filled, Automotive Grade for Specialized Applications

✅ Excellent Chemical & Thermal Resistance – Low Moisture Absorption for Optimal Performance Standards

✅ Multi-Industry Compatible – Enhanced Automotive, Electronics, Aerospace & Industrial Engineering Properties

✅ Automotive Components, Electronic Housings, Aerospace Parts & High-Temperature Engineering Applications

High-Quality PPA Resin for Automotive Engineering, Electronics Components & Aerospace Applications

PPA Resin (Polyphthalamide) represents advanced engineering thermoplastic technology specifically formulated for automotive manufacturing, electronics components, aerospace applications, industrial equipment, and demanding engineering operations requiring exceptional heat resistance, chemical resistance, and multi-industry engineering effectiveness. This essential semi-crystalline aromatic polyamide serves critical functions across automotive systems, electronic devices, aerospace components, and specialized engineering applications requiring controlled thermal stability, mechanical strength, and processing capabilities with exceptional reliability.

At Chemicals & Process Equipment Limited, we supply high-performance PPA Resins manufactured under stringent quality control standards and international engineering specifications. Our comprehensive product range includes automotive grade PPA, glass-filled formulations, mineral-filled compounds, and custom engineering grades meeting diverse requirements for automotive manufacturing, electronics applications, aerospace components, and specialized engineering solutions across global automotive, electronics, aerospace, and industrial markets.

✅ Advanced Engineering Thermoplastic Technology – Optimized Processing Properties & Multi-Industry Engineering Performance

✅ Consistent Quality Standards – Multiple Grade Classifications with Comprehensive Technical Documentation

✅ Essential Semi-Crystalline Aromatic Polyamide – Superior Automotive, Electronics & Aerospace Engineering Performance

✅ Multi-Industry Engineering Applications – Automotive, Electronics, Aerospace & Industrial Systems

✅ Technical Support Package – Complete Application Guidance & Performance Optimization

The global polyphthalamide (PPA) resin market size was valued at USD 1.7 billion in 2024 and is estimated to grow at a CAGR of over 5.1% from 2025 to 2034, while the global Polyphthalamide (PPA) Resin market size was valued at approximately USD 1.2 billion in 2023 and is projected to reach a market size of USD 2.3 billion by 2032, growing at a CAGR of around 7.2% during the forecast period. This growth is driven by increasing automotive demand, expanding electronics manufacturing, growing aerospace applications, and rising high-temperature engineering requirements across global automotive and industrial markets.

Technical Specifications & PPA Resin Properties

| Property | Unfilled Grade | 30% Glass-Filled | 40% Glass-Filled | 30% Mineral-Filled |

|---|---|---|---|---|

| Density (g/cm³) | 1.12-1.18 | 1.35-1.42 | 1.45-1.52 | 1.38-1.45 |

| Melt Flow Rate (g/10min) | 8-25 | 3-12 | 2-8 | 4-15 |

| Tensile Strength (MPa) | 90-120 | 160-210 | 180-240 | 140-180 |

| Elongation at Break (%) | 4-8 | 2-4 | 1.5-3 | 2.5-5 |

| Flexural Strength (MPa) | 140-180 | 240-310 | 280-360 | 200-260 |

| Flexural Modulus (GPa) | 2.8-3.5 | 9-12 | 12-16 | 7-10 |

| Impact Strength (kJ/m²) | 6-12 | 8-15 | 6-12 | 7-14 |

| Heat Deflection Temperature (°C) | 280-310 | 305-325 | 310-330 | 295-315 |

| Melting Point (°C) | 310-320 | 310-320 | 310-320 | 310-320 |

| Glass Transition Temperature (°C) | 125-135 | 125-135 | 125-135 | 125-135 |

| Service Temperature (°C) | -40 to +200 | -40 to +220 | -40 to +230 | -40 to +210 |

| Thermal Conductivity (W/m·K) | 0.23-0.28 | 0.35-0.45 | 0.45-0.55 | 0.30-0.40 |

| Coefficient of Expansion (×10⁻⁵/°C) | 5.0-7.0 | 2.5-4.0 | 2.0-3.5 | 3.0-5.0 |

| Dielectric Strength (kV/mm) | 18-25 | 16-22 | 15-20 | 17-23 |

| Volume Resistivity (Ω·cm) | >10¹⁴ | >10¹³ | >10¹³ | >10¹³ |

| Water Absorption (%) | 0.8-1.2 | 0.4-0.8 | 0.3-0.6 | 0.5-0.9 |

| Chemical Resistance | Excellent | Excellent | Excellent | Excellent |

| UV Resistance | Good-Excellent | Good-Excellent | Good-Excellent | Good-Excellent |

| Flame Retardancy | V-2 (additive grades V-0) | V-2 (additive grades V-0) | V-2 (additive grades V-0) | V-2 (additive grades V-0) |

| Processing Method | Injection molding, extrusion | |||

| Crystallinity (%) | 20-35 | 20-35 | 20-35 | 20-35 |

| Processing Temperature (°C) | 320-360 | 320-370 | 330-380 | 320-370 |

| Mold Temperature (°C) | 120-150 | 130-160 | 140-170 | 125-155 |

| Injection Pressure (MPa) | 100-150 | 120-180 | 140-200 | 110-160 |

| Screw Speed (rpm) | 40-120 | 40-100 | 30-90 | 40-110 |

| Drying Required | Yes (4-8 hours at 120°C) | Yes | Yes | Yes |

| Storage Conditions | Cool, dry environment, moisture-free | |||

| Shelf Life | 60 months | |||

| Packaging Options | 25kg bags, octabins, bulk containers |

Available Grade Types:

- Automotive Grade for vehicle components and systems

- Electronics Grade for electrical and electronic applications

- Aerospace Grade for aviation and space applications

- Glass-Filled Grades (15%, 30%, 40%, 50%) for enhanced strength

- Mineral-Filled Grades for dimensional stability

- Flame Retardant Grades for safety applications

- Conductive Grades for anti-static applications

- Impact Modified Grades for toughness requirements

- Heat Stabilized Grades for extreme temperature applications

- Food Contact Grades for specialized applications

- Medical Grades for healthcare applications

- Wear Resistant Grades for tribological applications

Specialized Processing Solutions:

- Injection molding for precision automotive components

- Extrusion for continuous profiles and tubes

- Blow molding for specialized containers

- Thermoforming for automotive panels

- Compression molding for large components

- Rotational molding for hollow parts

- 3D printing for prototyping applications

- Machining for precision components

Automotive & Transportation Applications

Engine Components & Systems Automotive manufacturers utilize PPA Resin for engine components, cooling system parts, and powertrain applications requiring automotive specifications. Vehicle manufacturers employ PPA resins for intake manifolds, thermostat housings, and engine component applications.

Transmission & Drivetrain Components Transmission manufacturers use PPA Resin for gear components, transmission housings, and drivetrain parts requiring transmission specifications. Automotive suppliers employ PPA resins for shift forks, bearing cages, and transmission component applications.

Fuel System Components Fuel system manufacturers utilize PPA Resin for fuel pumps, fuel rails, and fuel system components requiring fuel system specifications. Automotive companies employ PPA resins for fuel connectors, fuel filters, and fuel system applications.

Electrical & Electronic Systems Automotive electronics manufacturers use PPA Resin for connector housings, sensor components, and electrical systems requiring automotive electronics specifications. Vehicle suppliers employ PPA resins for ECU housings, wiring harnesses, and automotive electronic applications.

Electronics & Electrical Applications

Connector Systems & Components Electronics manufacturers utilize PPA Resin for electrical connectors, terminal blocks, and connection systems requiring electronics specifications. Connector companies employ PPA resins for high-temperature connectors, power connectors, and electrical connection applications.

Circuit Protection Components Circuit breaker manufacturers use PPA Resin for breaker housings, switch components, and protection devices requiring circuit protection specifications. Electrical companies employ PPA resins for fuse holders, relay housings, and electrical protection applications.

Motor & Generator Components Electric motor manufacturers utilize PPA Resin for motor housings, rotor components, and electrical machine parts requiring motor specifications. Generator companies employ PPA resins for insulation components, brush holders, and electrical machine applications.

Power Electronics & Components Power electronics manufacturers use PPA Resin for power device housings, heat sinks, and thermal management requiring power electronics specifications. Electronics companies employ PPA resins for transformer components, inductor housings, and power component applications.

Aerospace & Defense Applications

Aircraft Engine Components Aerospace manufacturers utilize PPA Resin for turbine components, engine housings, and propulsion systems requiring aerospace specifications. Aircraft companies employ PPA resins for fan blades, compressor components, and aerospace engine applications.

Structural Components & Systems Aircraft manufacturers use PPA Resin for structural brackets, interior components, and airframe parts requiring aerospace structural specifications. Aviation companies employ PPA resins for seat components, cabin parts, and aircraft structural applications.

Avionics & Electronic Systems Avionics manufacturers utilize PPA Resin for electronic housings, radar components, and navigation systems requiring avionics specifications. Aerospace electronics companies employ PPA resins for antenna housings, control systems, and avionics applications.

Satellite & Space Components Space manufacturers use PPA Resin for satellite components, space equipment, and orbital systems requiring space specifications. Aerospace companies employ PPA resins for solar panel components, spacecraft parts, and space applications.

Industrial & Manufacturing Applications

Heavy Equipment Components Industrial equipment manufacturers utilize PPA Resin for machinery housings, equipment components, and industrial systems requiring heavy equipment specifications. Manufacturing companies employ PPA resins for pump housings, valve components, and industrial equipment applications.

Chemical Processing Equipment Chemical manufacturers use PPA Resin for process equipment, chemical containers, and processing systems requiring chemical processing specifications. Process companies employ PPA resins for reactor components, piping systems, and chemical processing applications.

Oil & Gas Components Energy manufacturers utilize PPA Resin for downhole tools, pipeline components, and oil field equipment requiring oil & gas specifications. Energy companies employ PPA resins for drilling components, production equipment, and energy applications.

Mining & Construction Equipment Mining equipment manufacturers use PPA Resin for equipment housings, wear components, and mining systems requiring mining specifications. Construction companies employ PPA resins for tool housings, equipment parts, and construction applications.

Consumer & Appliance Applications

Small Appliance Components Appliance manufacturers utilize PPA Resin for heating elements, motor housings, and appliance components requiring appliance specifications. Consumer companies employ PPA resins for coffee makers, toasters, and small appliance applications.

Kitchen & Cookware Products Cookware manufacturers use PPA Resin for cooking utensils, kitchen tools, and food preparation requiring cookware specifications. Kitchen companies employ PPA resins for pot handles, cooking implements, and kitchen applications.

Personal Care & Beauty Products Personal care manufacturers utilize PPA Resin for styling tools, beauty devices, and personal care equipment requiring beauty specifications. Consumer companies employ PPA resins for hair dryers, curling irons, and personal care applications.

Sports & Recreation Equipment Sports equipment manufacturers use PPA Resin for sporting goods, recreational equipment, and performance products requiring sports specifications. Recreation companies employ PPA resins for golf components, fitness equipment, and sports applications.

Quality Control & Testing Procedures

Comprehensive Quality Assurance Every production batch undergoes extensive testing to ensure compliance with automotive standards, electronics requirements, aerospace specifications, and international quality requirements. Our quality control laboratory employs advanced analytical techniques including thermal analysis, mechanical testing, and chemical resistance evaluation. PPA is stronger, stiffer, less sensitive to moisture, and has higher thermal capabilities compared to nylon 6/6, with exceptional heat resistance and good dimensional stability.

Quality assurance procedures include:

- Thermal analysis using DSC and TGA methods

- Mechanical property testing using universal testing machine

- Impact resistance testing using Charpy and Izod methods

- Chemical resistance testing using solvent immersion

- Heat deflection temperature testing using HDT apparatus

- Melt flow rate testing using melt indexer

- Density measurement using density gradient column

- Moisture absorption testing using controlled humidity chambers

- Automotive material testing (ASTM, ISO, SAE standards)

- Electronics material testing (UL, IEC standards)

- Aerospace material testing (ASTM, AMS standards)

- Long-term thermal aging testing

- Fatigue and creep testing under load

- Flammability testing using cone calorimeter

- UV resistance testing using weatherometer

- Processing performance evaluation using pilot equipment

Application Guidelines & Best Practices

Injection Molding Guidelines Establish proper molding procedures for PPA Resin including temperature control, mold design, and processing parameters for optimal part quality and production efficiency in automotive and electronics applications.

Thermal Management Develop appropriate thermal processing procedures including temperature profiles, heating rates, and cooling methods for maximum processing performance and component quality in high-temperature applications.

Storage & Handling Procedures Implement proper storage conditions including moisture protection, temperature control, and contamination prevention for maintaining PPA resin quality and processing performance throughout storage periods.

Market Applications & Industry Trends

Automotive Industry Growth Expanding vehicle electrification and growing automotive technology markets drive continued growth in automotive-grade PPA applications for components, systems, and automotive engineering solutions across global automotive operations.

Electronics Manufacturing Expansion Growing electronics demand and expanding high-performance device markets support increased adoption of electronics-grade PPA for housings, connectors, and electronic component applications worldwide.

Aerospace Development Expanding aerospace manufacturing and growing aircraft complexity drive growth in aerospace-grade PPA applications for components, structures, and aerospace system applications.

Environmental & Regulatory Compliance

Automotive Standards & Certifications PPA Resins comply with automotive material standards, SAE specifications, and international automotive guidelines ensuring safe use in automotive applications and vehicle systems.

Electronics Standards & Safety Adherence to UL standards, IEC regulations, and international electronics guidelines supports responsible use in electronic devices and electrical component applications.

Aerospace Standards & Requirements Compliance with aerospace material standards, FAA regulations, and international aviation guidelines ensures appropriate use in aircraft and aerospace applications.

Performance Advantages & Technical Benefits

✔ Exceptional Heat Resistance – Superior thermal stability for high-temperature applications up to 230°C

✔ Outstanding Chemical Resistance – Resistance to fuels, oils, coolants, and aggressive chemicals

✔ Superior Mechanical Properties – High strength, stiffness, and dimensional stability

✔ Low Moisture Absorption – Minimal water uptake for stable properties

✔ Excellent Fatigue Resistance – Outstanding performance under cyclic loading

✔ High Creep Resistance – Maintains properties under long-term loading

✔ Good Electrical Properties – Excellent insulation and dielectric properties

✔ Dimensional Stability – Low warpage and excellent dimensional control

✔ Processing Versatility – Suitable for injection molding and extrusion

✔ Lightweight Alternative – Replacement for metal components

✔ Flame Resistance – Available with flame retardant properties

✔ UV Stability – Good resistance to ultraviolet radiation and weathering

Our PPA Resin products represent industry-leading standards in engineering thermoplastic technology and multi-industry engineering solutions, specifically formulated for demanding automotive operations, electronics applications, aerospace components, and specialized industrial engineering applications. We provide comprehensive technical support, processing guidance, and application consultation to ensure optimal performance across your specialized automotive, electronics, aerospace, or industrial engineering applications.

For comprehensive information about PPA resin properties, processing guidelines, and applications, you can reference this detailed technical guide on polyphthalamide which provides extensive coverage of PPA characteristics and industrial uses.

For detailed specifications, technical data sheets, or application-specific recommendations, contact our specialized engineering plastics division. We offer complete support including processing optimization, equipment recommendations, and technical guidance to maximize effectiveness in your automotive, electronics, aerospace, or industrial engineering applications.

For more information about our products, feel free to Contact Us today.

Reviews

There are no reviews yet.