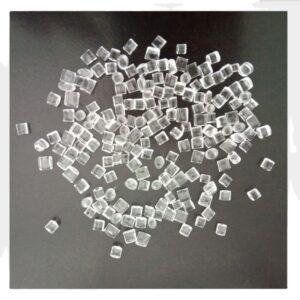

PET Resin Bottle Grade

PET Resin Bottle Grade – High Performance Packaging Material

Premium Quality PET Resin – Food Grade/Bottle Grade Polyethylene Terephthalate for Beverage Bottles, Food Packaging, Container Manufacturing & Plastic Bottle Production Applications

PET Resin Bottle Grade (Polyethylene Terephthalate) is a versatile high-performance thermoplastic polymer extensively utilized in beverage bottle production, food packaging manufacturing, container systems, and specialized packaging applications.

✅ Ultra-High Performance Thermoplastic – Superior Clarity & Multi-Industry Applications

✅ Multiple Viscosity Grades – IV 0.80-0.85 dL/g for Specialized Bottle Applications

✅ Excellent Processing Properties – Food Grade/Bottle Grade for Optimal Performance

✅ Multi-Industry Compatible – Enhanced Beverage, Food Packaging & Container Properties

✅ Beverage Bottles, Food Packaging, Container Manufacturing & Plastic Applications

High-Quality PET Resin for Beverage Bottle Production, Food Packaging & Container Manufacturing Applications

PET Resin Bottle Grade (Polyethylene Terephthalate) represents advanced thermoplastic polymer technology specifically formulated for beverage bottle manufacturing operations, food packaging systems, container production facilities, and packaging applications requiring consistent intrinsic viscosity and multi-industry effectiveness. This essential packaging material serves critical functions across bottle production procedures, food packaging processes, container manufacturing methods, and specialized systems requiring controlled processing characteristics, chemical resistance, and packaging performance capabilities with exceptional clarity.

At Chemicals & Process Equipment Limited, we supply food-grade PET Resin manufactured under stringent quality control standards and international specifications. Our comprehensive product range includes bottle grade PET resin, food packaging grade polymer, container grade polyethylene terephthalate, and custom formulations meeting diverse requirements for beverage bottles, food packaging, container manufacturing, and specialized operations across global packaging, beverage, food processing, and container manufacturing markets.

✅ Advanced Thermoplastic Polymer Technology – Optimized Viscosity Properties & Multi-Industry Performance

✅ Consistent Quality Standards – Multiple Viscosity Classifications with Comprehensive Documentation

✅ Essential Packaging Material – Superior Bottle, Food Packaging & Container Performance

✅ Multi-Industry Applications – Beverage, Food, Container & Packaging Systems

✅ Technical Support Package – Complete Application Guidance & Performance Optimization

The Global PET Resin Market is expected to grow from USD 28.6 Billion in 2024 to USD 42.8 Billion by 2031, at a CAGR of 5.9% during the forecast period, while the bottle grade PET market achieved a valuation of USD 18.2 billion in 2024 and is forecasted to climb to USD 26.8 billion by 2033, advancing at a CAGR of 4.7% from 2026 to 2033. This growth is driven by increasing beverage consumption, expanding food packaging demand, growing container manufacturing, and rising demand for sustainable packaging solutions across global beverage and packaging markets.

Technical Specifications & PET Resin Properties

| Property | Standard Grade | Premium Grade | Ultra Grade |

|---|---|---|---|

| Intrinsic Viscosity (dL/g) | 0.80-0.82 | 0.83-0.85 | 0.86-0.88 |

| Density (g/cm³) | 1.395-1.400 | 1.396-1.401 | 1.397-1.402 |

| Glass Transition Temp (°C) | 75-80 | 76-81 | 77-82 |

| Melting Point (°C) | 250-255 | 252-257 | 254-259 |

| Crystallization Temp (°C) | 120-130 | 125-135 | 130-140 |

| Moisture Content (%) | 0.02% max | 0.015% max | 0.01% max |

| Acetaldehyde Content (ppm) | 1.0 max | 0.8 max | 0.5 max |

| Diethylene Glycol (%) | 1.5% max | 1.2% max | 1.0% max |

| Color Value (b*) | 2.0 max | 1.5 max | 1.0 max |

| Haze (%) | 1.5% max | 1.0% max | 0.8% max |

| Yellowness Index | 5.0 max | 4.0 max | 3.0 max |

| Carboxyl End Groups (meq/kg) | 30 max | 25 max | 20 max |

| Thermal Stability (%) | 95% min | 96% min | 97% min |

| Processing Temperature (°C) | 270-290 | 275-295 | 280-300 |

| Melt Flow Rate (g/10min) | 12-18 | 15-20 | 18-25 |

| Tensile Strength (MPa) | 55-65 | 60-70 | 65-75 |

| Elongation at Break (%) | 200-300 | 250-350 | 300-400 |

| Flexural Modulus (GPa) | 2.8-3.2 | 3.0-3.4 | 3.2-3.6 |

| Impact Strength (kJ/m²) | 40-60 | 50-70 | 60-80 |

| Transparency (%) | 85-90 | 88-92 | 90-95 |

| Oxygen Permeability | Low | Very Low | Ultra Low |

| CO₂ Permeability | Moderate | Low | Very Low |

| Water Vapor Permeability | Low | Very Low | Ultra Low |

| Chemical Resistance | Excellent | Excellent | Excellent |

| UV Resistance | Good | Very Good | Excellent |

| Food Contact Approval | FDA/EU approved | ||

| Recyclability | 100% recyclable | ||

| Storage Temperature | 10-40°C | ||

| Storage Humidity | <60% RH | ||

| Shelf Life | 24 months | ||

| Packaging Options | Big bags, octabins, silos |

Available Grade Types:

- Bottle Grade for beverage and container applications

- Food Grade for direct food contact packaging

- Hot Fill Grade for high-temperature filling processes

- Barrier Grade for enhanced gas barrier properties

- Crystal Clear Grade for maximum transparency

- Lightweight Grade for thin-wall applications

- Recycled Content Grade for sustainability

- Custom Grades for specialized applications

Specialized Packaging Solutions:

- 25kg big bags for small-scale operations

- 500kg octabins for medium-scale production

- 1000kg big bags for large-scale manufacturing

- Bulk silos for continuous production lines

- Moisture-barrier packaging for humid climates

- Nitrogen-flushed packaging for quality preservation

- Temperature-controlled storage for quality maintenance

- Clean room packaging for pharmaceutical applications

Beverage Bottle Applications

Water Bottle Manufacturing Beverage manufacturers utilize PET Resin Bottle Grade for water bottle production, bottled water packaging, and hydration products requiring food-grade quality. Water bottling facilities employ PET resin for single-serve bottles, multi-pack containers, and bulk water packaging.

Carbonated Beverage Bottles Soft drink manufacturers use PET Resin for carbonated beverage bottles, soda containers, and pressurized packaging requiring high barrier properties. Beverage companies employ PET resin for gas retention, pressure resistance, and product quality protection.

Juice & Sports Drink Containers Beverage processors utilize PET Resin for juice bottles, sports drink containers, and functional beverage packaging requiring clarity and flavor protection. Drink manufacturers employ PET resin for product visibility, shelf appeal, and consumer convenience.

Hot Fill Beverage Applications Hot fill processors use PET Resin for tea bottles, coffee drinks, and pasteurized beverage containers requiring hot fill grade quality. Beverage companies employ specialized PET resin for thermal processing and product safety.

Food Packaging Applications

Food Container Manufacturing Food packaging manufacturers utilize PET Resin for food containers, take-away packaging, and food service applications requiring food-grade certification. Packaging companies employ PET resin for microwaveable containers, fresh food packaging, and convenience foods.

Condiment & Sauce Bottles Food processors use PET Resin for condiment bottles, sauce containers, and culinary product packaging requiring chemical resistance. Food companies employ PET resin for product protection, extended shelf life, and consumer convenience.

Edible Oil Bottles Oil manufacturers utilize PET Resin for edible oil bottles, cooking oil containers, and liquid food packaging requiring barrier properties. Food processors employ PET resin for product freshness, UV protection, and handling durability.

Dairy Product Packaging Dairy processors use PET Resin for milk bottles, yogurt containers, and dairy product packaging requiring food safety standards. Dairy companies employ PET resin for product protection, transparency, and consumer appeal.

Personal Care & Cosmetics Applications

Shampoo & Body Care Bottles Personal care manufacturers utilize PET Resin for shampoo bottles, body wash containers, and personal hygiene products requiring cosmetic grade quality. Beauty companies employ PET resin for product presentation, dispensing convenience, and brand appeal.

Cosmetic Packaging Cosmetic manufacturers use PET Resin for cosmetic bottles, beauty product containers, and makeup packaging requiring clarity and design flexibility. Beauty brands employ PET resin for premium appearance, product visibility, and marketing appeal.

Pharmaceutical Bottles Pharmaceutical companies utilize PET Resin for medicine bottles, supplement containers, and healthcare packaging requiring pharmaceutical grade quality. Drug manufacturers employ PET resin for product protection, tamper evidence, and regulatory compliance.

Household Chemical Containers Chemical manufacturers use PET Resin for household cleaners, detergent bottles, and chemical product packaging requiring chemical resistance. Consumer product companies employ PET resin for safety, durability, and consumer protection.

Industrial & Technical Applications

Chemical Packaging Chemical manufacturers utilize PET Resin for chemical bottles, industrial containers, and specialty chemical packaging requiring technical grade quality. Industrial companies employ PET resin for chemical compatibility, worker safety, and handling convenience.

Automotive Fluid Bottles Automotive manufacturers use PET Resin for automotive fluid bottles, lubricant containers, and vehicle maintenance products requiring automotive grade quality. Auto companies employ PET resin for product integrity, storage stability, and service convenience.

Agricultural Chemical Containers Agricultural companies utilize PET Resin for pesticide bottles, fertilizer containers, and agricultural chemical packaging requiring agricultural grade quality. Farm chemical manufacturers employ PET resin for product safety, application convenience, and regulatory compliance.

Laboratory & Scientific Bottles Laboratory suppliers use PET Resin for laboratory bottles, scientific containers, and research packaging requiring laboratory grade quality. Scientific institutions employ PET resin for sample storage, chemical compatibility, and analytical accuracy.

Specialty Packaging Applications

Wide Mouth Jars & Containers Specialty manufacturers utilize PET Resin for wide mouth jars, specialty containers, and custom packaging requiring specialized processing. Packaging companies employ PET resin for unique applications, custom designs, and niche markets.

Tubes & Dispensing Bottles Packaging manufacturers use PET Resin for squeeze tubes, dispensing bottles, and convenience packaging requiring flexible processing. Consumer product companies employ PET resin for portion control, ease of use, and product dispensing.

Blister Pack Applications Pharmaceutical packaging companies utilize PET Resin for blister packs, unit dose packaging, and medical device packaging requiring pharmaceutical grade quality. Medical device manufacturers employ PET resin for sterile packaging, product protection, and regulatory compliance.

Thermoformed Packaging Thermoforming companies use PET Resin for thermoformed containers, custom packaging, and specialized applications requiring thermoforming grade quality. Packaging manufacturers employ PET resin for complex shapes, custom designs, and specialty applications.

Recycling & Sustainability Applications

Post-Consumer Recycled (PCR) Products Recycling facilities utilize PET Resin for PCR bottle production, sustainable packaging, and circular economy applications requiring recycled content certification. Sustainability-focused companies employ recycled PET resin for environmental responsibility and corporate sustainability goals.

Bottle-to-Bottle Recycling Recycling processors use PET Resin for bottle-to-bottle recycling, closed-loop systems, and sustainable manufacturing requiring food-grade recycled quality. Beverage companies employ recycled PET resin for environmental stewardship and sustainability commitments.

Fiber & Textile Applications Textile manufacturers utilize recycled PET Resin for polyester fiber production, textile applications, and clothing manufacturing requiring textile grade quality. Fashion companies employ recycled PET resin for sustainable fashion, eco-friendly products, and environmental consciousness.

Construction & Building Materials Construction companies use recycled PET Resin for building materials, construction applications, and infrastructure projects requiring construction grade quality. Building material manufacturers employ recycled PET resin for sustainable construction and green building initiatives.

Quality Control & Testing Procedures

Comprehensive Quality Assurance Every production batch undergoes extensive testing to ensure compliance with international standards, industrial specifications, and application requirements. Our quality control laboratory employs advanced analytical techniques including intrinsic viscosity measurement, thermal analysis, and performance testing. For comprehensive information about PET resin properties, safety guidelines, and packaging applications, visit Plastics Industry Association which provides detailed technical data about plastic materials, sustainability practices, and industry standards for packaging applications.

Quality assurance procedures include:

- Intrinsic viscosity measurement using viscometry methods

- Thermal properties analysis using DSC and TGA

- Density measurement using pycnometer methods

- Moisture content determination using Karl Fischer titration

- Color measurement using colorimetric analysis

- Acetaldehyde content analysis using GC-MS methods

- Molecular weight distribution using GPC analysis

- Thermal stability testing under processing conditions

- Barrier properties evaluation using permeation testing

- Clarity and haze measurement using optical methods

- Mechanical properties testing using tensile analysis

- Food contact compliance verification

Application Guidelines & Best Practices

Processing Parameter Optimization Establish proper processing conditions for PET Resin including melt temperature, injection pressure, and cooling parameters for optimal bottle quality and production efficiency.

Drying Procedures Develop appropriate material drying protocols including temperature control, residence time, and moisture targets for preventing hydrolysis and maintaining polymer properties.

Mold Design Guidelines Implement proper mold design principles including gate placement, cooling systems, and venting for achieving uniform wall thickness and defect-free bottles.

Storage & Handling Procedures Implement proper storage conditions including moisture protection, temperature control, and contamination prevention for maintaining PET resin quality and processing performance throughout storage periods.

Market Applications & Industry Trends

Beverage Industry Growth Expanding beverage consumption and growing demand for convenient packaging drive continued growth in bottle grade PET applications for beverage bottles and drink containers across global markets.

Food Packaging Expansion Growing food packaging requirements and increasing demand for fresh food containers support increased adoption of food grade PET for food packaging and convenience applications.

Sustainability Development Expanding recycling initiatives and growing environmental awareness drive growth in recycled PET applications and sustainable packaging solutions.

E-commerce Packaging Growth Increasing online commerce and growing shipping requirements support continued adoption of PET packaging for e-commerce applications and product protection.

Environmental & Regulatory Compliance

Food Contact Regulations PET Resin complies with FDA food contact regulations, EU packaging standards, and international guidelines ensuring safe use in food and beverage packaging applications.

Environmental Standards Compliance with environmental regulations, recycling requirements, and sustainability guidelines supports responsible manufacturing and end-of-life management.

Packaging Safety Standards Adherence to packaging safety regulations, consumer protection standards, and quality specifications ensures safe use in consumer packaging applications.

International Quality Standards Compliance with ISO packaging standards, ASTM specifications, and international guidelines ensures consistent performance in global packaging applications.

Performance Advantages & Technical Benefits

✔ Multiple Viscosity Grades – Available in IV 0.80-0.88 dL/g for specialized applications

✔ Excellent Clarity – Superior transparency for product visibility and appeal

✔ Multi-Industry Versatility – Suitable for beverage, food, personal care, and industrial uses

✔ Chemical Resistance – Excellent resistance to acids, bases, and solvents

✔ Barrier Properties – Low permeability to gases and moisture for product protection

✔ Processing Efficiency – Optimized melt flow for efficient bottle production

✔ Cost Effectiveness – Economical packaging solution for diverse applications

✔ Quality Consistency – Reliable viscosity with comprehensive analytical documentation

✔ Environmental Compatibility – 100% recyclable with established recycling infrastructure

✔ Food Safety – FDA and EU approved for direct food contact applications

✔ Regulatory Compliance – Meets packaging, food contact, and environmental standards

✔ Technical Support – Complete processing guidance and optimization assistance

Our PET Resin Bottle Grade products represent industry-leading standards in packaging material technology and multi-industry bottle manufacturing solutions, specifically formulated for demanding beverage bottle production, food packaging manufacturing, container systems, and packaging applications. We provide comprehensive technical support, processing guidance, and regulatory consultation to ensure optimal performance across your specialized bottle manufacturing, food packaging, or container production applications.

For detailed specifications, certificates of analysis, or application-specific recommendations, contact our specialized polymers division. We offer complete support including processing optimization, regulatory guidance, and technical assistance to maximize effectiveness in your beverage bottle manufacturing, food packaging, personal care packaging, or industrial container applications.

For more information about our products, feel free to Contact Us today.

Reviews

There are no reviews yet.