Lauryl alcohol/Dodecanol C12

Lauryl Alcohol/Dodecanol C12

Premium Quality Dodecanol – Technical Grade for Surfactant Manufacturing, Cosmetic Production, Personal Care Formulations & Specialized Chemical Processing Applications

Lauryl Alcohol (Dodecanol) is a highly versatile fatty alcohol extensively utilized in surfactant manufacturing, cosmetic production, personal care formulations, and specialized chemical processing applications.

✅ High-Purity Lauryl Alcohol/Dodecanol – Superior Quality & Multi-Industry Performance

✅ Multiple Purity Grades – 98%, 99%, 99.5% for Specialized Applications

✅ Excellent Surfactant Properties – Technical Grade for Optimal Performance Standards

✅ Multi-Functional Chemical – Emulsifier, Thickener & Stabilizer Properties

✅ Detergent, Cosmetic, Personal Care & Chemical Processing Applications

High-Quality Lauryl Alcohol for Surfactant Manufacturing, Cosmetic Production & Personal Care Systems

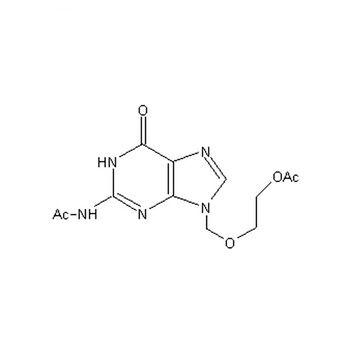

Lauryl Alcohol/Dodecanol C12 (CH3(CH2)11OH) represents advanced fatty alcohol technology specifically formulated for surfactant manufacturing, cosmetic production, personal care formulations, and chemical processing operations requiring consistent purity and multi-functional performance characteristics. This essential fatty alcohol serves critical functions across detergent manufacturing procedures, cosmetic applications, personal care formulations, and specialty processes requiring controlled emulsification, thickening properties, and stabilization capabilities with exceptional processing performance.

At Chemicals & Process Equipment Limited, we supply technical-grade Lauryl Alcohol manufactured under stringent quality control standards and international specifications. Our comprehensive product range includes surfactant grade dodecanol, cosmetic grade, personal care grade, and custom formulations meeting diverse requirements for detergent manufacturing operations, cosmetic production, personal care systems, and specialized applications across global surfactant, cosmetic, personal care, and chemical processing markets.

For comprehensive information about lauryl alcohol applications in surfactant manufacturing and its critical role in detergent production, we recommend reading this detailed research: Fatty Alcohols from Wikipedia, which provides extensive scientific insights into surfactant chemistry and manufacturing optimization strategies.

✅ Advanced Fatty Alcohol Technology – Optimized Surfactant Properties & Multi-Industry Performance

✅ Multi-Functional Processing Chemical – Emulsifier and Comprehensive Quality Documentation

✅ Essential Surfactant Properties – Superior Emulsification, Thickening & Stabilization Performance

✅ Multi-Industry Applications – Detergent, Cosmetic, Personal Care & Chemical Processing Systems

✅ Technical Support Package – Complete Application Guidance & Performance Optimization

The Lauryl Alcohol Market is expected to grow from USD 1,150.00 Million in 2024 to USD 1,625.30 Million by 2031, at a CAGR of 5.02% during the forecast period. Additionally, Lauryl Alcohol Market Size estimated to grow by USD 158.75 million from 2023-2028 with demand from personal care and detergent industries, while surfactant grade captured 54.20% of lauryl alcohol market share in 2024, and the segment is projected to advance at a 5.67% CAGR through 2030. This growth is driven by increasing personal care consumption, expanding detergent production, growing cosmetic applications, and rising demand for bio-based surfactants across global personal care, detergent, and chemical processing markets.

Technical Specifications & Lauryl Alcohol Properties

| Property | 98.0% Grade | 99.0% Grade | 99.5% Grade |

|---|---|---|---|

| Lauryl Alcohol Content (%) | 98.0% min | 99.0% min | 99.5% min |

| Dodecanol (C12) Content | 98.0% min | 99.0% min | 99.5% min |

| C10 Alcohol Content | 1.5% max | 0.8% max | 0.3% max |

| C14 Alcohol Content | 1.0% max | 0.5% max | 0.2% max |

| Other Alcohols | 0.5% max | 0.3% max | 0.1% max |

| Moisture Content | 0.2% max | 0.1% max | 0.05% max |

| Acid Value (mg KOH/g) | 0.5 max | 0.3 max | 0.1 max |

| Saponification Value | 2.0 max | 1.0 max | 0.5 max |

| Iodine Value | 1.0 max | 0.5 max | 0.3 max |

| Hydroxyl Value (mg KOH/g) | 295-305 | 298-302 | 299-301 |

| Color (APHA) | 20 max | 15 max | 10 max |

| Odor | Characteristic mild | ||

| Carbonyl Value (ppm) | 100 max | 50 max | 25 max |

| Peroxide Value | 2.0 max | 1.0 max | 0.5 max |

| Heavy Metals (as Pb) | ≤10 ppm | ≤5 ppm | ≤3 ppm |

| Iron (Fe) | ≤5 ppm | ≤3 ppm | ≤2 ppm |

| Copper (Cu) | ≤2 ppm | ≤1 ppm | ≤0.5 ppm |

| Nickel (Ni) | ≤2 ppm | ≤1 ppm | ≤0.5 ppm |

| Ash Content | 0.02% max | 0.01% max | 0.005% max |

| Cloud Point (1% aq. solution) | 20-25°C | 22-24°C | 22-24°C |

| Flash Point | >110°C | >110°C | >110°C |

| Appearance at 25°C | White waxy solid | ||

| Melting Point | 24-26°C | 24-26°C | 24-26°C |

| Boiling Point | 259°C | 259°C | 259°C |

| Density at 25°C | 0.830-0.835 g/cm³ | 0.831-0.834 g/cm³ | 0.832-0.833 g/cm³ |

| Viscosity at 25°C | 15-20 cP | 16-19 cP | 17-18 cP |

| Solubility in Water | Slightly soluble | ||

| Solubility in Ethanol | Completely soluble | ||

| HLB Value | 15.5 | 15.5 | 15.5 |

| Surface Tension (0.1% aq.) | 30-35 mN/m | 30-35 mN/m | 30-35 mN/m |

| CMC (Critical Micelle Conc.) | 0.1 mM | 0.1 mM | 0.1 mM |

| Storage Stability | 24 months | 24 months | 24 months |

| Storage Temperature | 15-30°C | 15-30°C | 15-30°C |

| Packaging Options | Drums, IBC, bulk tankers, bags |

Available Grade Types:

- Surfactant Grade for detergent manufacturing

- Cosmetic Grade for personal care products

- Personal Care Grade for skincare formulations

- Technical Grade for industrial processing

- Pharmaceutical Grade for specialized uses

- Food Grade for food industry applications

- Bio-based Grade for sustainable applications

- Export Grade for international markets

- Custom Grade for specialized formulations

Specialized Packaging Solutions:

- 200kg steel drums with nitrogen blanketing

- 1000L IBC containers for bulk applications

- Bulk tankers for large-scale operations

- 25kg bags for small-scale users

- Heated packaging for cold climates

- Stainless steel containers for high-purity grades

- Custom packaging for specific requirements

- Temperature-controlled shipping options

Surfactant Manufacturing Applications

Detergent Production Detergent manufacturers utilize Lauryl Alcohol for surfactant synthesis, cleaning product manufacturing, and detergent applications requiring superior cleaning performance and biodegradability. Chemical companies employ dodecanol for liquid detergents, powder detergents, fabric softeners, and cleaning formulations requiring excellent foaming and cleaning properties.

Anionic Surfactant Manufacturing Chemical manufacturers use Lauryl Alcohol for sodium lauryl sulfate production, surfactant synthesis, and industrial applications requiring high-performance anionic surfactants. Surfactant companies employ dodecanol for SLS manufacturing, SLES production, and specialty surfactant formulations requiring premium raw materials.

Non-ionic Surfactant Production Surfactant manufacturers utilize Lauryl Alcohol for ethoxylate production, non-ionic surfactant synthesis, and industrial applications requiring low-foaming surfactants. Chemical companies employ dodecanol for laureth production, alkoxylate manufacturing, and specialty surfactant applications.

Industrial Cleaning Products Industrial manufacturers use Lauryl Alcohol for industrial cleaners, degreasing formulations, and specialized cleaning applications requiring heavy-duty cleaning performance. Chemical companies employ dodecanol for automotive cleaners, metal cleaners, and industrial cleaning formulations.

Cosmetic Production Applications

Skincare Formulations Cosmetic companies utilize Lauryl Alcohol for skincare products, moisturizer production, and cosmetic applications requiring emulsification and texture enhancement. Beauty companies employ dodecanol for creams, lotions, serums, and skincare formulations requiring superior skin feel and stability.

Hair Care Products Personal care manufacturers use Lauryl Alcohol for shampoo production, conditioner manufacturing, and hair care applications requiring cleansing and conditioning properties. Cosmetic companies employ dodecanol for hair styling products, treatments, and hair care formulations requiring performance enhancement.

Makeup & Color Cosmetics Cosmetic manufacturers utilize Lauryl Alcohol for makeup production, color cosmetics, and beauty applications requiring texture improvement and product stability. Beauty companies employ dodecanol for foundations, lipsticks, eyeshadows, and color cosmetics requiring superior application properties.

Anti-aging Products Cosmetic companies use Lauryl Alcohol for anti-aging formulations, premium skincare, and cosmetic applications requiring advanced delivery systems and product performance. Personal care manufacturers employ dodecanol for serums, treatments, and anti-aging products requiring superior efficacy.

Personal Care Applications

Body Care Products Personal care manufacturers utilize Lauryl Alcohol for body wash production, soap manufacturing, and personal care applications requiring gentle cleansing and moisturizing properties. Consumer goods companies employ dodecanol for shower gels, body lotions, and personal cleansing products.

Baby Care Formulations Personal care companies use Lauryl Alcohol for baby care products, gentle formulations, and specialized applications requiring mild and safe ingredients. Consumer companies employ dodecanol for baby shampoos, lotions, and baby care products requiring exceptional gentleness.

Oral Care Products Oral care manufacturers utilize Lauryl Alcohol for toothpaste production, mouthwash manufacturing, and oral care applications requiring foaming and cleaning properties. Personal care companies employ dodecanol for dental products and oral hygiene formulations.

Deodorant & Antiperspirant Personal care manufacturers use Lauryl Alcohol for deodorant production, antiperspirant formulations, and personal care applications requiring stability and performance enhancement. Consumer goods companies employ dodecanol for roll-on deodorants and antiperspirant products.

Chemical Processing Applications

Plasticizer Manufacturing Chemical manufacturers utilize Lauryl Alcohol for plasticizer production, polymer additives, and chemical applications requiring specialty chemical intermediates. Plasticizer companies employ dodecanol for phthalate-free plasticizers and specialty polymer additives.

Lubricant Production Lubricant manufacturers use Lauryl Alcohol for synthetic lubricant production, metalworking fluids, and industrial applications requiring high-performance lubricating properties. Chemical companies employ dodecanol for specialty lubricants and metalworking applications.

Textile Processing Textile manufacturers utilize Lauryl Alcohol for fabric processing, textile auxiliaries, and textile applications requiring wetting agents and processing aids. Textile companies employ dodecanol for dyeing processes, finishing operations, and textile chemical formulations.

Paint & Coating Applications Paint manufacturers use Lauryl Alcohol for coating formulations, paint production, and industrial applications requiring emulsification and stability enhancement. Coating companies employ dodecanol for water-based paints, architectural coatings, and specialty paint formulations.

Agricultural Applications

Agricultural Adjuvants Agricultural companies utilize Lauryl Alcohol for adjuvant production, pesticide formulations, and agricultural applications requiring spray enhancement and coverage improvement. Agrochemical companies employ dodecanol for herbicide adjuvants, fungicide formulations, and agricultural spray applications.

Crop Protection Products Pesticide manufacturers use Lauryl Alcohol for crop protection formulations, agricultural chemicals, and specialty applications requiring enhanced biological activity. Agricultural companies employ dodecanol for insecticide formulations and crop protection products.

Fertilizer Manufacturing Fertilizer companies utilize Lauryl Alcohol for liquid fertilizer production, nutrient formulations, and agricultural applications requiring enhanced nutrient delivery. Agricultural manufacturers employ dodecanol for foliar fertilizers and specialty agricultural products.

Animal Health Products Veterinary companies use Lauryl Alcohol for animal health formulations, veterinary products, and specialized applications requiring safe and effective delivery systems. Animal health manufacturers employ dodecanol for topical treatments and veterinary care products.

Food Industry Applications

Food Processing Operations Food manufacturers utilize Lauryl Alcohol for food processing, manufacturing operations, and food applications requiring food-grade processing aids and emulsification properties. Food companies employ dodecanol for specialized food processing and manufacturing applications.

Food Additive Manufacturing Food additive companies use Lauryl Alcohol for additive production, food ingredient manufacturing, and food applications requiring emulsification and processing enhancement. Specialty food companies employ dodecanol for food-grade applications.

Beverage Production Beverage manufacturers utilize Lauryl Alcohol for beverage processing, production operations, and specialty applications requiring processing aids and quality enhancement. Beverage companies employ dodecanol for specialized beverage applications.

Confectionery Applications Confectionery manufacturers use Lauryl Alcohol for candy production, chocolate processing, and confectionery applications requiring texture enhancement and processing improvement. Food companies employ dodecanol for specialty confectionery applications.

Quality Control & Testing Procedures

Comprehensive Quality Assurance Every production batch undergoes extensive testing to ensure compliance with cosmetic standards, surfactant specifications, and international requirements. Our quality control laboratory employs advanced analytical techniques including GC-MS, HPLC, and spectroscopic analysis.

Quality assurance procedures include:

- Alcohol content determination using gas chromatography

- Purity analysis using GC-MS spectroscopy

- Moisture content testing using Karl Fischer titration

- Acid value determination using titration methods

- Hydroxyl value measurement using acetylation method

- Color measurement using APHA standards

- Heavy metals analysis using ICP-MS spectroscopy

- Odor evaluation using sensory analysis

- Surface tension measurement using tensiometry

- Cloud point determination using standard methods

- Viscosity measurement using rotational viscometry

- Melting point determination using DSC analysis

Application Guidelines & Best Practices

Surfactant Manufacturing Guidelines Establish proper processing procedures for Lauryl Alcohol including reaction optimization, temperature control, and quality monitoring for optimal surfactant production and performance characteristics.

Cosmetic Formulation Procedures Develop appropriate formulation procedures including emulsification techniques, stability testing, and compatibility assessment for cosmetic and personal care applications.

Storage & Handling Procedures Implement proper storage conditions including temperature control, moisture protection, and contamination prevention for maintaining lauryl alcohol quality and preventing oxidation.

Market Applications & Industry Trends

Personal Care Market Growth Expanding personal care consumption and growing beauty market demand drive continued growth in lauryl alcohol applications for cosmetic production, skincare formulations, and personal care manufacturing operations.

Surfactant Industry Development Growing detergent production, increasing cleaning product demand, and expanding industrial applications support increased adoption of lauryl alcohol for surfactant manufacturing and chemical processing.

Bio-based Product Demand Rising environmental awareness and sustainability requirements drive growth in bio-based lauryl alcohol for eco-friendly formulations and sustainable product development.

Environmental & Regulatory Compliance

Cosmetic Standards Lauryl Alcohol complies with cosmetic regulations, personal care guidelines, and international beauty standards ensuring safe and effective use in cosmetic and personal care applications.

Surfactant Regulations Compliance with detergent regulations, surfactant standards, and environmental guidelines ensures appropriate use in cleaning products and industrial applications.

Food Safety Standards Adherence to food safety regulations, FDA guidelines, and international food standards supports responsible use in food-grade and food contact applications.

Performance Advantages & Technical Benefits

✔ Multi-Functional Performance – Emulsifier, thickener, and stabilizer properties

✔ Excellent Surfactant Properties – Superior foaming and cleaning performance

✔ Multi-Industry Versatility – Suitable for surfactant, cosmetic, personal care, and food applications

✔ Biodegradability – Environmentally friendly and sustainable properties

✔ Skin Compatibility – Gentle and safe for personal care applications

✔ Processing Enhancement – Improved manufacturability and product quality

✔ Thermal Stability – Excellent temperature resistance and stability

✔ Cost-Effective Solution – Economical multi-functional ingredient

✔ Quality Consistency – Reliable composition with comprehensive quality control

✔ Regulatory Compliance – Meets cosmetic, surfactant, and food standards

✔ Storage Stability – Good shelf life with proper storage conditions

✔ Technical Support – Complete application guidance and optimization assistance

Our Lauryl Alcohol/Dodecanol products represent industry-leading standards in fatty alcohol technology and multi-industry solutions, specifically formulated for demanding surfactant manufacturing operations, cosmetic production, personal care formulations, and specialized chemical processing requirements. We provide comprehensive technical support, application guidance, and regulatory consultation to ensure optimal performance across your specialized surfactant, cosmetic, personal care, or chemical processing applications.

For detailed specifications, certificates of analysis, or application-specific recommendations, contact our specialized chemicals division. We offer complete support including application optimization, regulatory guidance, and technical assistance to maximize effectiveness in your surfactant manufacturing, cosmetic production, personal care, or chemical processing applications.

For more information about our products, feel free to Contact Us today.

Reviews

There are no reviews yet.